bit25825-sup-0001-SuppData

advertisement

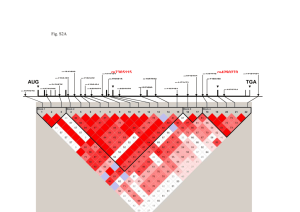

Supplementary Information: Arsenic remediation by formation of arsenic sulfide minerals in a continuous anaerobic bioreactor Lucia Rodriguez-Freirea#, Sarah E. Moorea, Reyes Sierra-Alvareza, Robert A. Rootb, Jon Choroverb, and James A. Fielda a Department of Chemical and Environmental Engineering, The University of Arizona P.O. Box 210011, Tucson, Arizona, USA b Department of Soil, Water and Environmental Science, The University of Arizona P.O. Box 210038, Tucson, Arizona, USA # Corresponding author: Department of Chemical and Environmental Engineering, University of Arizona, P.O. Box 210011, Tucson, Arizona Tel. 520-621-2591 Fax. 520-621-6048 E-mail: luciar@email.arizona.edu SI Table of Contents S1. Materials and methods................................................................................................... S1.1. Arsenic mass balance in the reactors....................................................................... S1.2. Analytical techniques............................................................................................... S2. Results.............................................................................................................................. S2.1.Endogenous activity of the inoculum....................................................................... S2.2. Sulfide loss during stage I in R1.............................................................................. S2.3. Solid phase characterization.................................................................................... Tables..................................................................................................................................... Table S1. Arsenic speciation by HPLC-ICP-MS.............................................................. Table S2. As K-edge EXAFS linear combination fits (LCF)........................................... Table S3. As K-edge EXAFS non-linear least squares fits (shell-by-shell)..................... Figures................................................................................................................................... Fig. S1. Schematic of bioreactors..................................................................................... Fig. S2. pH and retention time (HRT) for all three stages................................................ Fig. S3. Sloss/Asloss for reactor 1.................................................................................... Fig. S4. SEM Micrographs with EDS............................................................................... References.............................................................................................................................. 2 2 2 5 5 5 5 7 7 8 8 9 9 10 11 12 13 S1. Materials and methods S1.1. Arsenic mass balance in the reactors At the end of stage III, the bioreactors were sealed and transferred to an anaerobic chamber (Coy Laboratory Products, Inc., Grass Lake, MI). The reactors were emptied through a sieve to separate the liquid and the solid phases. The liquid phase was collected in a serum bottle. The solid phase was homogenized and samples were taken for acid extraction and for solid characterization. The acid extraction was performed in triplicate using 50 mg of solid in 4 mL of aqua regia (HCl:HNO3, 3:1) for total As content (AsTot). A mass balance analysis of the cumulative removal of As over the 176 d of operation (stages II and III) and the amount of As precipitated in the reactors was determined at the end of the experiment. The total cumulative As immobilized from the influent in reactor 1 was 7.59 g, which corresponded to a concentration of 915.8 mg As/g VSS of sludge. The As extracted from the solid phase was 898.1 ±2.4 mg As/g VSS, which corresponds to a 98.1% recovery of the total As immobilized in the sludge bed compared to that lost during the operation of the reactor. These results demonstrate a great capacity of the anaerobic sludge to retain the ASM precipitated in the reactor. The amount of As retained in reactor 2 (R2) was below the detectable limit. S.1.2.Analytical techniques Total As concentration was measured by using an inductively coupled plasma-optical emission spectrometry (ICP-OES) system model Optima 2100 DV from Perkin–Elmer TM (Shelton, CT, USA) monitored at wavelength 193.7 nm. Arsenate and SO42- were analyzed by suppressed conductivity ion chromatography using a Dionex IC-3000 system (Sunnyvale, CA, USA) fitted 2 with a Dionex IonPac AS11 analytical column (4 mm x 250 mm) and AG11 guard column (4 mm x 50 mm). The injection eluent (KOH) was 23 mM for 10 min. Selected samples were sent for As speciation to detect AsIII, AsV, methylarsonic acid (MMAV) and dimethylarsonious acid (DMAV) using a high pressure liquid chromatography system (Agilent 1100 HPLC, Agilent Technologies, Inc.) with a reverse-phase C18 column (Gemini 5µ C18 110A, 150 mm x 4.60 mm, Phenomenex, Torrance, CA) and guard cartridge. The mobile phase (pH 5.85) contained 4.7 mM tetrabutylammonium hydroxide, 2 mM malonic acid, and 4% (v/v) methanol at a flow rate of 1.2 ml min-1. The column temperature was maintained at 50oC and samples are kept at 4oC in a thermally controlled autosampler. Following HPLC separation, As species were detected using an ICP-mass spectrometer (ICP-MS) (Agilent 7500ce) with a conical nebulizer (Glass Expansion). The operating parameters were as follows: RF power 1500 watts, plasma gas flow 15 L/min, carrier flow ~ 0.9 L/min, makeup gas 0.15 L/min, and arsenic monitored at mass 75. Detection limits for the measured species were (all in µg/L): 0.03 AsIII, 0.17 AsV, 0.11 DMAV, 0.15 MMAV, and 0.05 total As. In reactor 2, AsV and total As concentrations were measured once every other day, with AsIII calculated by difference. In order to validate the previous assumption, seven sets of samples, evenly distributed over the operation time of the reactors, were sent to an external lab for As speciation. The concentrations of organoarsenicals, methylarsonic acid (MMAV) and dimethylarsonious acid (DMAV) were below detection limits in all samples (Table S1). Dissolved sulfide ( = H2S(aq) + HS- + S2-) was determined using the methylene blue method (Truper, 1964) and measured using a UV-visible spectrophotometer (Agilent 8453, Palo Alto, CA, USA). Hereafter dissolved sulfide is referred to as H2S(aq). Ethanol and acetate were measured using an Agilent Technologies 7890A gas chromatography system. Ethanol and acetate 3 were monitored using a Restek Stabilwax®-DA Column (30 m x 0.35 mm, ID 0.25 µm) with flame ionization detector, and He used as a carried gas. Scanning electron microscopy (SEM) was performed in a Hitachi S-4800N Type II with a cold field emission electron gun and an accelerant voltage of 20 kV. The SEM was combined with a ThermoNORAN microanalyzer for energy dispersive spectroscopy (EDS). The samples were vacuum dry and crushed to a powder material. Then, the samples were adhered to a metallic base and coated with platinum. Arsenic K-edge X-ray absorption spectra (XAS) were acquired at the Stanford Synchrotron Radiation Lightsource (SSRL) on beamline 11-2 under dedicated conditions (3 GeV, 300 mA) using an unfocused beam detuned 40% to remove high energy harmonics calibrated to Au foil edge jump inflection defined as 11919 eV. Solid samples were characterized by XAS with X-ray absorption near-edge structure (XANES) and extended x-ray absorption finestructure (EXAFS). Samples were loaded as wet pastes into 0.5 mm thick aluminum sample holders and sealed with kapton tape in an anaerobic glovebag (Coy, MI). To avoid X-ray beam induced redox changes, all samples were collected in a LN2 cryostat sample holder (77 K), with the sample position moved at least 1 mm (always greater than the X-ray beam size) between scans to expose a fresh cross-sectional area of sample to the X-ray beam. Collected spectra (3-5 scans) were averaged in SixPack and background subtracted using a linear fit through the pre-edge region, spectra were normalized to unity about the average height of the post-edge absorbance oscillation, and a cubic spline was fit through the EXAFS region above the absorption edge using EXAFSPAK software packages. Normalized EXAFS spectra were fit by linear combination least squares fits to model spectra of orpiment and realgar using the Athena, and shell by shell fits were performed with the OPT package within EXAFPAK. S2. Results 4 S2.1.Endogenous activity of the inoculum The endogenous substrate decay of the anaerobic biofilm was obtained by measuring the CH4 produced by 50 mg wet wt of sludge incubated with 10 ml of mineral medium over a 7 d period. The experiment was performed in 25 mL culture tubes, closed with butyl rubber septum and aluminum seals, and flushed with N2/CO2 to ensure anaerobic conditions. 0.21±0.04 mM of CH4 were produced after 7 d, which corresponded to 8 e- meq/g VSS. The endogenous decay rate was as high as 2.57 e- meq/(g VSS∙d) during the first two days of incubation and then it stabilized at 0.57 e- meq/(g VSS∙d) for the rest of the experiment. S2.2. Sulfide loss during stage I in R1 The presence of metals (Fe, Co and Mn) in the medium (as trace elements) could account for 15.5% of the observed Sloss by precipitating H2S(aq) as metal sulfides, H2S stripping due to low levels of biogas production could only account for an additional 2.7% of this Sloss. Therefore, the bulk of the loss is attributed to low levels of dissolved oxygen (DO) inadvertently entering reactor with the influent. As an example, a DO in the influent of 2 mg/L (25% saturation with air) would account for up to 50% of the observed Sloss in stage I by oxidizing H2S(aq) to elemental S. S2.3. Solid phase characterization The solid phase was analyzed using SEM-EDS. The precipitated mineral formed compositeaggregates with the biofilm in the reactor of approximately 20 μm diameter (Fig. S4). A closer look to one of the aggregate shows small particles of minerals (less than 100 nm) surrounding or coating the different bacteria. At two distinct points, at a mineral surface (point 1) and at a 5 bacterium (point 2), EDS was collected. The EDS confirmed the presence of an ASM. The counts for As and S were similar for both points indicating the bulk extracellular precipitate had a similar elemental composition as the mineral precipitates associated with the bacteria. 6 Table S1. Actual values of the samples send for As speciation. Reactor 1 Influent DMA MMA AsIII AsV (mM) (mM) (mM) (mM) below LODa 1.16 below LOD 1.02 below LOD 1.03 below LOD 0.93 below LOD 1.08 below LOD 0.95 below LOD 1.00 V Date 1/10/2013 2/1/2014 3/7/2014 4/5/2014 5/1/2013 6/5/2013 6/26/2014 Reactor 2 1/10/2013 2/1/2014 3/7/2014 4/5/2014 5/1/2013 6/5/2013 6/26/2014 a V below LOD below LOD below LOD below LOD below LOD below LOD below LOD 1.13 1.02 1.05 1.00 1.15 1.01 0.96 Total As (mM) 1.10 1.00 1.01 0.92 1.05 0.92 1.01 1.10 0.99 1.03 0.95 1.15 0.96 0.92 V DMA (mM) V MMA (mM) below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD below LOD Effluent AsIII AsV (mM) (mM) 0.12 0.11 0.12 0.09 0.16 0.16 0.12 0.72 1.00 0.98 1.00 0.84 0.81 0.87 0.10 0.04 0.09 0.08 0.19 0.15 0.12 Total As (mM) 0.14 0.12 0.12 0.08 0.16 0.16 0.12 0.76 0.99 1.02 1.01 1.02 1.00 0.97 LOD, limit of detection, 0.03 ppb AsIII, 0.17 ppb AsV, 0.11 ppb DMAV, 0.15 ppb MMAV, 0.05 ppb total As, shaded regions were below the respective detection limit. 7 Table S2. Arsenic K-edge linear combination fits Orpimenta Realgarb Re c red 2 d 1.0 0.65 0.35 0.78 0.102 0.42 0.58 1.0 2.88 0.526 Sample 1 Sample 2 est. errorf 0.04 0.05 Fit from 2 to 12.5 k(Å-1) with a b from O'Day et al., (2004); c total of the component fits; dReduced chi-square 1 𝑑𝑎𝑡𝑎 𝑟𝑒𝑑 𝜒 2 = ( ∑𝑁 − 𝑦𝑖𝑚𝑜𝑑𝑒𝑙 𝑥) /(𝑁𝑖𝑛𝑑 − 𝑁𝑓𝑖𝑡 𝑝𝑎𝑟 ), N is the number of independent and fit variables, yi 𝑖 [𝑦𝑖 𝑁 = experimental data and simulated model; eR-value = ∑[(𝑑𝑎𝑡𝑎 − 𝑓𝑖𝑡)2 /(𝑑𝑎𝑡𝑎)2 ] ; festimated error on the contribution of each component. Table S3. Arsenic K-edge EXAFS shell by shell fit results Sample Orpimentb Realgarb Sample 1c 65% orpiment 35% realgar Sample 2d 40% orpiment 60% realgar Atoma N S As S As As S As As As S S As As S As AS S S As As S As AS S 3.0 1.0 1.0 1.0 1.0 2.0 1.0 2.5 1.5 2.5 2.7 0.4 0.7 0.7 0.9 1.2 1.5 2.4 0.6 0.4 0.4 1.5 1.3 1.9 R (Å) 2.27 3.17 3.20 3.55 3.69 2.24 2.57 3.42 3.53 3.67 2.27 2.56 3.12 3.21 3.42 3.52 3.67 2.27 2.56 3.13 3.34 3.37 3.57 3.74 2 (Å2) 0.005 0.005 0.005 0.004 0.010 0.004 0.005 0.005 0.004 0.051 0.004 0.004 0.005 0.004 0.048 0.011 0.019 0.005 0.005 4 0.004 0.004 0.005 0.009 0.009 E0 (eV) -8.9 2 F 0.44 0.24 -12.1 0.38 0.26 -10.34 0.69 0.30 -11.1 1.4 0.53 a Atom is the As-near neighbor ligand (S, As), N is the number of backscattering atoms at distance R (Å); 2, the Debye-Waller term, is the absorber-backscatterer mean-square relative displacement; E0 is the threshold energy difference; 2 is a reduced least-squares goodness-of-fit parameter (=F-factor/(# of points - # of variables) and F = [Σk6(χexptl-χcalcd)2/Σk6χexptl2]1/2), Scale factor (S02) = 1. b N was fixed, R and 2 were allowed to adjust for reference minerals, cThe realgar and orpiment components were allowed to vary as a weighted group in the fit. dSpectrum fit with defined scattering paths from realgar and orpiment, overlapping shells, e.g. the first scattering path As-S was fit as a single shell of the weighted sum of As-S. 8 Fig. S1 Schematic of the bioreactors used in this study. 9 Fig. S2. Actual pH and hydraulic retention time (HRT) of the reactor 1 (A) and reactor 2 (B). (♦) HRT; (●) pH of the influent; (○) pH on the effluent. The vertical dashed lines indicate the separation between the three stages in the reactor. The shaded area designates the stage II of operation, right after the addition of AsV. The horizontal grey lines represent the theoretical target values of pH and HRT. 10 I II Fig. S3. Calculated Sloss/Asloss ratio over the operation in reactor 1. The vertical dashed line indicates the separation between stages II and III in the reactor. The shaded area designates the stage II of operation, right after the addition of AsV. The horizontal grey lines represent the theoretical stoichiometric values for the precipitation of AsS (1) and for the precipitation of As2S3 (1.5). 11 A B C Fig. S4. SEM – EDS analysis of the precipitate from reactor 1. Sample was taken 170 d after the addition of AsV. (A) The image on the top left shows the granules packed with bacteria and precipitate (scale bar = 20 μm). (B) The image on the top right is a zoom in on one of the granules, where it can be notice the different shapes of bacteria and the precipitate (scale bar = 5 μm). (C) Finally, the bottom left shows the image of the bacterium and precipitate that were used for the EDS analysis (scale bar = 5 μm). EDS shows unambiguous As and S peaks, confirmed with > 10 keV peak; the small Al and Pt are from the sample prep. 12 References O'Day PA, Vlassopoulos D, Root R, Rivera N. 2004. The influence of sulfur and iron on dissolved arsenic concentrations in the shallow subsurface under changing redox conditions. P Natl Acad Sci USA 101(38):13703-13708. Omil F, Lens P, Visser A, Pol LWH, Lettinga G. 1998. Long-term competition between sulfate reducing and methanogenic bacteria in UASB reactors treating volatile fatty acids. Biotechnol and Bioeng 57(6):676-685. Truper HG. 1964. Sulphur metabolism in Thiorhodaceae .2. Stoichiometric relationship of CO2 fixation to oxidation of hydrogen sulphide and intracellular sulphur in Chromatium okenii. A Van Leeew J Microb Serol 30(4):385-394. Weijma J, Gubbels F, Pol LWH, Stams AJM, Lens P, Lettinga G. 2002. Competition for H-2 between sulfate reducers, methanogens and homoacetogens in a gas-lift reactor. Water Sci Technol 45(10):75-80. 13