Chapter 11 Supplement

Transportation and

Transshipment Models

Just how do you make decisions?

•

•

•

•

•

Emotional direction

Intuition

Analytic thinking

Are you an intuit, an analytic, what???

How many of you use models to make

decisions??

Supplement 10-2

Problems

• Arise whenever there is a perceived difference

between what is desired and what is in

actuality.

• Problems serve as motivators for doing

something

• Problems lead to decisions

42

How many of you have used a model

before?

• Any kind of model??

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-4

Supplement 10-5

Model Classification Criteria

• Purpose

• Perspective

• Use the perspective of the targeted decision-maker

•

•

•

•

Degree of Abstraction

Content and Form

Decision Environment

{This is what you should start any modeling

facilitation meeting with}

Supplement 10-6

Purpose

•

•

•

•

Planning

Forecasting

Training

Behavioral research

Supplement 10-7

Perspective

• Descriptive

• “Telling it like it is”

• Most simulation models are of this type

• Prescriptive

• “Telling it like it should be”

• Most optimization models are of this type

Supplement 10-8

Degree of Abstraction

• Isomorphic

• One-to-one

• Homomorphic

• One-to-many

Supplement 10-9

Content and Form

•

•

•

•

•

verbal descriptions

mathematical constructs

simulations

mental models

physical prototypes

Supplement 10-10

Decision Environment

• Decision Making Under Certainty

• TOOL: all of mathematical programming—supplements

to Chapters 11 and 14

• Decision Making under Risk and Uncertainty

• TOOL: Decision analysis--tables, trees, Bayesian

revision—supplement to Chapter 1

• Decision Making Under Change and Complexity

• TOOL: Structural models, simulation models—

supplement to Chapter 13

Supplement 10-11

We will cover parts of….

•

•

•

•

The supplements to Chapters 11, 14 and 13

In that order

Network programming—suppl to Chap 11 today

Linear programming—suppl to Chap 14

tomorrow

• Simulation—suppl to Chap 13 Friday

• And test you on this on July 30

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-12

Mathematical Programming

• Linear programming

• Integer linear programming

• some or all of the variables are integer variables

• Network programming (produces all integer

solutions)

•

•

•

•

Nonlinear programming

Dynamic programming

Goal programming

The list goes on and on

• Geometric Programming

Supplement 10-13

Network Programming

•

•

•

•

•

•

•

Transportation model

Transhipment model

Shortest Route model (not covered)

Minimal Spanning Tree (not covered)

Maximal Flow model (not covered)

Assignment model (not covered)

Many other models

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-14

A Model of this class

• What would we include in it?

Supplement 10-15

Management Science Models: A Definition

• A QUANTITATIVE REPRESENTATION OF A

PROCESS THAT CONSISTS OF THOSE

COMPONENTS THAT ARE SIGNIFICANT FOR

THE ________ BEING CONSIDERED

Supplement 10-16

Mathematical programming models covered

in Ch 11, Supplement

• Transportation Model

• Transshipment Model

Not included are:

Shortest Route

Minimal Spanning Tree

Maximal flow

Assignment problem

many others

Supplement 10-17

Transportation Model

• A model formulated for a class of problems

with the following characteristics

• items are transported from a number of sources to

a number of destinations at minimum cost

• each source supplies a fixed number of units

• each destination has a fixed demand for units

• Solution Methods

• stepping-stone (by hand—a heuristic algorithm)

• modified distribution

• Excel’s Solver (uses Dantzig’s Simplex

optimization algorithm)

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-18

Transportation Method Example

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-19

Transportation Method

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-20

Problem Formulation with Excel

1. Click on “Data”

2. Solver

=C5+D5+E5

=E5+E6+E7

Total cost formula for all

potato shipments in cell C10

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-21

Solver Parameters

Total cost

Click to “solve”

Decision variables

representing

shipment routes

Constraints specifying

that supply at the

distribution centers

equals demand

at the plants

Click on “Options”

to activate “Assume

Linear Models”

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-22

Solution

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-23

The Underlying Network

Supplement 10-24

Copyright 2006 John Wiley & Sons, Inc.

Modified Problem Solution

High cost prohibits

route C5

Copyright 2011 John Wiley & Sons, Inc.

Column “H” added

for excess supply

Supplement 11-25

Modified Problem Settings

Constraint changed

to ≤ to reflect

supply > demand

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-26

OM Tools

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-27

Transshipment Model

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-28

Transshipment Model Solution

=SUM(B6:B7)

=SUM(B6:D6)

=SUM(C13:E13)

=SUM(C13:C15)

=C8-F14

Copyright 2011 John Wiley & Sons, Inc.

= B8-F13, the amount shipped

into KC equals the amount

shipped out

Supplement 11-29

Transshipment Settings

Transshipment constraints

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-30

For problems in which there is an

underlying network:

• There are easy (fast) solutions

• An exception is the traveling salesman problem

• The solutions are always integer ones

• {How about solving a 50,000 node problem in

less than a minute on a laptop??}

Supplement 10-31

CARLTON PHARMACEUTICALS

• Carlton Pharmaceuticals supplies drugs and other

medical supplies.

• It has three plants in: Cleveland, Detroit,

Greensboro.

• It has four distribution centers in:

Boston, Richmond, Atlanta, St. Louis.

• Management at Carlton would like to ship cases

of a certain vaccine as economically as possible.

Supplement 10-32

• Data

• Unit shipping cost, supply, and demand

From

From

Cleveland

Cleveland

Detroit

Detroit

Greensboro

Greensboro

Demand

Demand

Boston

Boston

$35

$35

37

37

40

40

1100

1100

• Assumptions

Richmond

Richmond

30

30

40

40

15

15

400

400

To

To

Atlanta

Atlanta

40

40

42

42

20

20

750

750

St.

St.Louis

Louis

32

32

25

25

28

28

750

750

Supply

Supply

1200

1200

1000

1000

800

800

• Unit shipping cost is constant.

• All the shipping occurs simultaneously.

• The only transportation considered is between sources

and destinations.

• Total supply equals total demand.

Supplement 10-33

Sources

NETWORK

REPRESENTATION

Destinations

D1=1100

Boston

Cleveland

Richmond

S1=1200

D2=400

Detroit

S2=1000

Atlanta

D3=750

Greensboro

S3= 800

Supplement 10-34

St.Louis

D4=750

• The Associated Linear Programming Model

• The structure of the model is:

Minimize <Total Shipping Cost>

ST

[Amount shipped from a source] = [Supply at that source]

[Amount received at a destination] = [Demand at that

destination]

• Decision variables

Xij = amount shipped from source i to destination j.

where: i=1 (Cleveland), 2 (Detroit), 3 (Greensboro)

j=1 (Boston), 2 (Richmond), 3 (Atlanta),

4(St.Louis)

Supplement 10-35

Supply from Cleveland X11+X12+X13+X14 = 1200

Supply from Detroit X21+X22+X23+X24

= 1000

Supply from Greensboro X31+X32+X33+X34 = 800

The supply constraints

Boston

D1=1100

X11

Cleveland

S1=1200

X12

X13

X21

X31

Richmond

X14

X22

Detroit

D2=400

X32

X23

S2=1000

X24

Atlanta

X33

St.Louis

Greensboro

S3= 800

X34

Supplement 10-36

D3=750

D4=750

• The complete mathematical programming

model

Minimize 35X11+30X12+40X13+ 32X14 +37X21+40X22+42X23+25X24+

40X31+15X32+20X33+38X34

ST

Supply constrraints:

X11+ X12+ X13+ X14

X21+ X22+ X23+ X24

X31+ X32+ X33+ X34

Demand constraints:

X11+

X12+

X13+

X21+

X31

X22+

X32

X23+

X14+

All Xij are

Supplement 10-37

X33

X24+

nonnegative

X34

= 1200

= 1000

= 800

= 1000

= 400

= 750

= 750

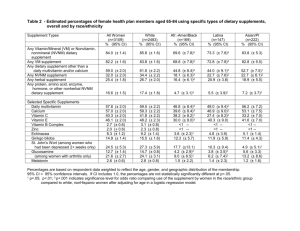

Excel Optimal Solution

CARLTON PHARMACEUTICALS

UNIT COSTS

BOSTON RICHMOND ATLANTA ST.LOUIS

CLEVELAND

$

35.00 $

30.00 $

40.00 $

32.00

DETROIT

$

37.00 $

40.00 $

42.00 $

25.00

GREENSBORO $

40.00 $

15.00 $

20.00 $

28.00

DEMANDS

1100

400

750

750

SHIPMENTS (CASES)

BOSTON RICHMOND ATLANTA ST.LOUIS

CLEVELAND

850

350

0

0

DETROIT

250

0

0

750

GREENSBORO

0

50

750

0

TOTAL

1100

400

SUPPLIES

1200

1000

800

750

TOTAL

1200

1000

800

750

TOTAL COST =

Supplement 10-38

84000

WINQSB Sensitivity Analysis

If this path is used, the total cost

will increase by $5 per unit

shipped along it

Supplement 10-39

Shadow prices for warehouses - the cost resulting from 1 extra case of vaccine

demanded at the warehouse

Shadow prices for plants - the savings incurred for each extra case of vaccine available at

the plant

Supplement 10-40

Transshipment

Model

Supplement 10-41

Transshipment Model: Solution

Supplement 10-42

DEPOT MAX

A General Network Problem

• Depot Max has six stores.

• Stores 5 and 6 are running low on the model

65A Arcadia workstation, and need a total of 25

additional units.

• Stores 1 and 2 are ordered to ship a total of 25

units to stores 5 and 6.

• Stores 3 and 4 are transshipment nodes with no

demand or supply of their own.

Supplement 10-43

• Other restrictions

• There is a maximum limit for quantities shipped on

various routes.

• There are different unit transportation costs for

different routes.

• Depot Max wishes to transport the available

workstations at minimum total cost.

Supplement 10-44

• DATA:

20

10

1

7

3

5

Arcs: Upper bound and lower bound constraints:

6

5

12

0 X ij U ij

2

15

4

11

7

15

–Supply nodes:

Network

presentation

6

Net flow out

of the node] nodes:

= [Supply at the node]

–Intermediate

transshipment

Transportation

X12

X15node]

- X21= =[Total

10 flow into the

(Node

1)

[Total

flow+ X13

out of+ the

node]

–Demand

nodes:

unit cost

X21

- X12

= 15

(Node

[Net flow

into +the

node]

= [Demand

for the node]

X34+X35

=X24

X13

(Node

3) 2)

X15 +X46

X35= +X65

X56 = 12

(Node 5)

X24 +- X34

(Node 4)

Supplement 10-45

X46

- X65

13

(Node 6)

Copyright

2006+X56

John Wiley

& Sons,=Inc.

• The Complete mathematical model

Minimize 5X12 10X13 20X15 6X21 15X24 12X34 7X35 15X46 11X56 7X65

ST

X12 + X13 + X15 - X21

- X12

= 10

+ X21 + X24

- X13

= 15

+ X34 + X35

- X24

- X15

- X34

= 0

+ X46

- X35

= 0

+ X56 - X65 = -12

- X46

- X56 + X65 = -13

0 X12 3; 0 X13 12; 0 X15 6; 0 X21 7; 0 X24 10; 0 X34 8; 0 X35 8;

0 X46 17; 0 X56 7; 0 X65 5

Supplement 10-46

WINQSB Input Data

Supplement 10-47

Copyright 2006 John Wiley & Sons, Inc.

WINQSB Optimal Solution

Supplement 10-48

Copyright 2006 John Wiley & Sons, Inc.

MONTPELIER SKI COMPANY

Using a Transportation model for production

scheduling

• Montpelier is planning its production of skis for the months

of

July, August, and September.

• Production capacity and unit production cost will change

from

month to month.

• The company can use both regular time and overtime to

produce skis.

• Production levels should meet both demand forecasts and

end-of-quarter inventory requirement.

• Management would like to schedule production to minimize

its costs for the quarter.

Supplement 10-49

• Data:

• Initial inventory = 200 pairs

• Ending inventory required =1200 pairs

• Production capacity for the next quarter = 400 pairs in

regular time.

= 200 pairs in

overtime.

• Holding cost rate is 3% per month per ski.

• ProductionForecasted

capacity, and

forecasted

demand

for this

Production

Production

Costs

Forecasted

Production

Production Costs

quarter

Month

Demand

Capacity

Month

Demand

Capacity Regular

RegularTime

Time Overtime

Overtime

July

400

1000

25

30

(in

cost

Julypairs of skis),

400 and production

1000

25 per unit

30 (by

August

600

800

26

32

August

600

800

26

32

months)

September

1000

400

29

37

September

Supplement 10-50

1000

400

29

37

• Analysis of demand:

• Net demand to satisfy in July = 400 - 200 = 200 pairs

•

Initial inventory

of Unit

costs= 600

•Analysis

Net demand

in August

Unitdemand

cost = [Unit

production =cost]

+ + 1200 = 2200 pairs

• Net

in September

1000

[Unit holding cost per month][the number of months stays in

Forecasted demand In house inventory

inventory]of Supplies:

• Analysis

•Example:

Production

capacities

thought

of as supplies.

A unit

producedare

in July

in Regular

time and sold in

•September

There arecosts

two sets

“supplies”:

25+ of

(3%)(25)(2

months) = $26.50

• Set 1- Regular time supply (production capacity)

• Set 2 - Overtime supply

Supplement 10-51

Network representation

Production

Month/period

1000

800

July

O/T

Aug.

R/T

25

25.75

26.50

0

30

30.90

31.80 +M

0

26

26.78

400

Aug.

O/T

Month

sold

July

+M

+M

32.96

200

Sept.

R/T

Sept.

O/T

Supplement 10-52

0

0

Aug.

600

Sept.

2200

Dummy

300

+M

0

29

400

+M

+M

32

200

Demand

Production Capacity

500

July

July

R/T

R/T

37

0

Source: July production in R/T

Source: Aug. production in O/T

Destination: July‘s demand.

Destination: Sept.’s demand

Unit cost= $25 (production)

32+(.03)(32)=$32.96

Unit cost =Production+one month holding cost

Supplement 10-53

Copyright 2006 John Wiley & Sons, Inc.

Supplement 10-54

Copyright 2006 John Wiley & Sons, Inc.

• Summary of the optimal solution

• In July produce at capacity (1000 pairs in R/T, and 500

pairs in O/T). Store 1500-200 = 1300 at the end of July.

• In August, produce 800 pairs in R/T, and 300 in O/T.

Store additional 800 + 300 - 600 = 500 pairs.

• In September, produce 400 pairs (clearly in R/T). With

1000 pairs

retail demand, there will be

(1300 + 500) + 400 - 1000 = 1200 pairs available for

shipment to

Ski Chalet.

Inventory +

Production Supplement 10-55

Demand

Problem 4-25

Supplement 10-56

Copyright 2006 John Wiley & Sons, Inc.

Supplement 10-57

Copyright 2006 John Wiley & Sons, Inc.

Supplement 10-58

Copyright 2006 John Wiley & Sons, Inc.

Supplement 10-59

Copyright 2006 John Wiley & Sons, Inc.

Supplement 10-60

Copyright 2006 John Wiley & Sons, Inc.

6.3 The Assignment Problem

• Problem definition

• m workers are to be assigned to m jobs

• A unit cost (or profit) Cij is associated with worker i

performing job j.

• Minimize the total cost (or maximize the total

profit) of assigning workers to job so that each

worker is assigned a job, and each job is

performed.

Supplement 10-61

BALLSTON ELECTRONICS

• Five different electrical devices produced on five

production lines, are needed to be inspected.

• The travel time of finished goods to inspection

areas depends on both the production line and the

inspection area.

• Management wishes to designate a separate

inspection area to inspect the products such that

the total travel time is minimized.

Supplement 10-62

• Data: Travel time in minutes from assembly

lines to inspection areas.

Assembly

Assembly

Lines

Lines

11

22

33

44

55

Supplement 10-63

AA

10

10

11

11

13

13

14

14

19

19

BB

44

77

88

16

16

17

17

Inspection

Inspection Area

Area

CC

66

77

12

12

13

13

11

11

DD

10

10

99

14

14

17

17

20

20

EE

12

12

14

14

15

15

17

17

19

19

NETWORK REPRESENTATION

Assembly Line

S1=1

1

Inspection Areas

A D1=1

S2=1

2

B

S3=1

3

C D3=1

S4=1

4

D

D4=1

S5=1

5

E

D5=1

Supplement 10-64

D2=1

• Assumptions and restrictions

• The number of workers equals the number of jobs.

• Given a balanced problem, each worker is assigned

exactly once, and each job is performed by exactly one

worker.

• For an unbalanced problem “dummy” workers (in case

there are more jobs than workers), or “dummy” jobs (in

case there are more workers than jobs) are added to

balance the problem.

Supplement 10-65

• Computer solutions

• A complete enumeration is not efficient even for

moderately large problems (with m=8, m! > 40,000

is the number of assignments to enumerate).

• The Hungarian method provides an efficient

solution procedure.

• Special cases

• A worker is unable to perform a particular job.

• A worker can be assigned to more than one job.

• A maximization assignment problem.

Supplement 10-66

6.5 The Shortest Path Problem

• For a given network find the path of minimum

distance, time, or cost from a starting point,

the start node, to a destination, the terminal

node.

• Problem definition

• There are n nodes, beginning with start node 1 and

ending with terminal node n.

• Bi-directional arcs connect connected nodes i and j

with nonnegative distances, d i j.

• Find the path of minimum total distance that connects

node 1 to node n.

Supplement 10-67

Fairway Van Lines

Determine the shortest route from Seattle to El Paso

over the following network highways.

Supplement 10-68

Seattle

1

497

180

3

432

Portland

Sac.

Reno

6

691

420

345

Bakersfield

114

13

Los Angeles

440

7

526

11

621

Denver 9

Las Vegas

108

155

Barstow

14

469

15

Albuque.

Phoenix

425

12

403

16

118

San Diego

Supplement 10-69

452

Kingman

207

386

17

8

102

432

280

Cheyenne

Salt Lake City

291

10

Butte

2

Boise

4

138

5

599

Tucson

18

314

19

El Paso

• Solution - a linear programming approach

Decision variables

1 if a truck travels on the highway from city i to city j

X ij

0 otherwise

Objective = Minimize S dijXij

Supplement 10-70

Subject to the following constraints:

1

Seattle

180

497

3

432

Portland

Butte

599

2

Boise

4

345

Salt Lake City

7

[The number of highways traveled out of Seattle (the start node)] = 1

X12 + X13 + X14 = 1

In a similar manner:

[The number of highways traveled into El Paso (terminal node)] = 1

X12,19 + X16,19 + X18,19 = 1

Supplement 10-71

Nonnegativity

constraints

[The number of highways used to travel into a city] =

[The number of highways traveled leaving the city].

For example, in Boise (City 4):

X14 + X34 +X74 = X41 + X43 + X47.

WINQSB Optimal Solution

Supplement 10-72

Copyright 2006 John Wiley & Sons, Inc.

• Solution - a network approach

The Dijkstra’s algorithm:

• Find the shortest distance from the “START” node to every

other node in the network, in the order of the closet nodes to

the “START”.

• Once the shortest route to the m closest node is determined,

the shortest route to the (m+1) closest node can be easily

determined.

• This algorithm finds the shortest route from the start to all the

nodes in the network.

Supplement 10-73

An illustration of the Dijkstra’s algorithm

+ 420

SLC.=

SLC

599

BUT.

BUT

691

+

CHY.

=

345 =

+ SLC

SLC.

SLC

497

SEA.

BOI

BOI

BOI.

Seattle

1

497

180

3

599

2

691

Boise

420

432

Portland

138

4

Reno

345

POR.

POR

180

180

Sac.

Salt Lake City

6

102

621

291

10

Bakersfield

Denver 9

… and so on

until the

Kingman

Barstow

whole network

15

12

14

Albuque.

isPheonix

covered.

11

280

Las Vegas

108

452

155

469

207

Supplement 10-74

8

432

114

+ 602 =

SACSAC.

Cheyene

440

7

526

5

+ 432 =

BOIBOI

Butte

13

Los Angeles

386

San Diego

403

16

118

17

425

Tucson

18

19

314

El Paso

6.6 The Minimal Spanning Tree

• This problem arises when all the nodes of a

given network must be connected to one

another, without any loop.

• The minimal spanning tree approach is

appropriate for problems for which redundancy

is expensive, or the flow along the arcs is

considered instantaneous.

Supplement 10-75

THE METROPOLITAN TRANSIT DISTRICT

• The City of Vancouver is planning the development of a

new light rail transportation system.

• The system should link 8 residential and commercial

centers.

• The Metropolitan transit district needs to select the set

of lines that will connect all the centers at a minimum

total cost.

• The network describes:

• feasible lines that have been drafted,

• minimum possible cost for taxpayers per line.

Supplement 10-76

SPANNING TREE

NETWORK

North Side

PRESENTATION

3

34

University

50

5

Business

District

39

4

West Side

45

1

8

35

2

City

Center

41

7

Supplement 10-77

6

South Side

Shopping

Center

East Side

• Solution - a network approach

• The algorithm that solves this problem is a very easy

(“trivial”) procedure.

• It belongs to a class of “greedy” algorithms.

• The algorithm:

• Start by selecting the arc with the smallest arc

length.

• At each iteration, add the next smallest arc length to

the set

of arcs already selected (provided no loop is

constructed).

• Finish when all nodes are connected.

• Computer solution

• Input consists of the number of nodes, the arc length,

and the network description.

Supplement 10-78

WINQSB Optimal Solution

Supplement 10-79

Copyright 2006 John Wiley & Sons, Inc.

OPTIMAL SOLUTION

NETWORK

REPRESENTATION

3

North Side

34

West Side

University

50

5

Business

District

39

4

45

Loop

1

8

35

2

City

Center

41

6

Total Cost = $236 million

7

Supplement 10-80

South Side

Shopping

Center

East Side

Copyright 2011 John Wiley & Sons, Inc.

All rights reserved. Reproduction or translation of this

work beyond that permitted in section 117 of the 1976

United States Copyright Act without express permission

of the copyright owner is unlawful. Request for further

information should be addressed to the Permission

Department, John Wiley & Sons, Inc. The purchaser

may make back-up copies for his/her own use only and

not for distribution or resale. The Publisher assumes no

responsibility for errors, omissions, or damages caused

by the use of these programs or from the use of the

information herein.

Copyright 2011 John Wiley & Sons, Inc.

Supplement 11-81