Final Presentation (Apr. 13, 2004)

University of Pittsburgh

Senior Design - BIOE 1161

April 13, 2004

Design of a More Efficient Heat

Exchanger for Inducing Hypothermia in Neonatal ECMO Cases

Adam Abdulally

Erin Aghamehdi

Kim Albrecht

Rebecca Hrutkay

Outline

• Background

• ECMO & Hypothermia

• Overview

• Re-design

• Audience

• Device Description

• Features & Benefits

• Project Objectives

• Spring 04

• Future

• Project Management

• Design Alternatives

• Quality Systems

• Experimental Design

• SA calculations

• Technologies

• Competitive Analysis

• Testing Requirements

• Projected Methods

ECMO Background

• Provides temporary cardiac and/or pulmonary support for patients with potentially reversible cardiac and/or respiratory failure

• ECMO Stats:

• 8000 neonatal patients over the last

8 years

Hypothermia Background

• Patient core body temperature : 32 - 34°C

• Helps to counteract a decrease in oxygenation by reducing the brain’s oxygen requirements.

• Neurological protection for patients with:

• Sever head trauma

• Cardiac/pulmonary distress

• Other pathologies

• Current methods:

• Medications

• Ice water baths

• Cooling blankets

• IV of 4°C crystalloid

Overview

• Cooling offers a way to provide neurological protection for a patient on ECMO.

• Current heat exchangers used on ECMO are not capable of rapidly inducing patient hypothermic conditions.

• Solution:

• Design of a more efficient heat exchanger that will work in conjunction with an ECMO circuit.

Overview

• Users:

• Neonatal ECMO patients

• Customers:

• Hospitals

• Perfusionists

• Customer Requirements:

• More efficient means of inducing

Hypothermia

Overview

• Current Re-design:

• Heat exchanger is compatible with existing water bath in circuit

• Modeled similar to an oxygenator

• Increased surface area for exchange – nonporous hollow polypropylene fibers

• Priming volume maintained (60mL vs. ~65-70mL)

Features & Benefits

• Needs/requirements of end-user:

• Rapidly and accurately cools patient to desired hypothermic temperature (32-34 °C)

• Gradual rewarming of the patient’s blood <1°C/

15mins

• No clot or thromboemboli formation

• Pressure sensor on outlet of heat exchanger

• Safety of end-user:

• No significant increase in required patient priming volume

• Biocompatibility

Project Objectives – Spring 04

• Establish project objective:

• Research efficient means of cooling

• Project documents:

• DHF, scientific paper, presentation

• Heat transfer calculations:

• Energy balance equations

• Calculation of overall heat transfer coefficient (U)

• Calculation of surface area (SA)

• Calculate the number of fibers and priming volume

• Development of fiber bundles in heat exchanger

• Design of outer shell

Project Objectives –

Future Direction

• Fabrication and assembly of device

• Wet-lab testing

• Analysis

• Possible redesign of device to fulfill any unmet requirements from previous device

Project Management

•

Individual Responsibilities:

K

E

B

A

Heat Transfer

SA

Priming

Volume

Heat

Exchanger

Re-Design

Testing Analysis Paper Docs.

Accomplishments

Remaining Tasks

Device Description

• Non-porous polypropylene microfibers encased in a clear PVC housing

• Efficient heat transfer (Thermal conductivity estimated at 11.7 W/mK from the Polymer

Handbook)

• Increased SA for exchange

• Counter-current flow maximizes heat transfer

• Blood flows within the fibers

• Decrease priming volume requirement at the expense of heat transfer

Design Alternatives

• Fall 2003:

• Cooling Block

• Reasons for Rejection:

• Surface area requirement

• Spring 2004:

• Hollow 3003 anodized aluminum tubing

• Reasons for Rejection:

• Could not achieve required surface area with a reasonable amount of tubes

• Large priming volume

• Manufacturing restraints

Quality System Considerations

• Manufacturability:

• Materials:

• Polypropylene microfibers

• PVC shell

• Polyurethane epoxy

• Methods:

• Ension manufacture of fibers

• Rapid prototyping or hand machining of PVC shell

• Human Factors:

• Ensures the safety and needs/requirements of the end user are met

• Regulatory:

• Class II

• Predicate devices: All companies producing blood heat exchangers

Experimental Design

• Heat transfer within patient can be correlated by the Pennes equation:

• Mathematical modeling was used to find the desired surface area (SA)

• Incorporation of SA into heat exchanger design

• Subsequent fiber and priming volume calculations

Engineering

Technologies/Methodologies

• Solidworks

7.5 in.

Competitive Analysis

• Competitors:

• Non-invasive surface cooling

• Other heat exchanger manufacturers (Medtronic,

Gish Biomedical, etc)

• Strengths:

• More efficient heat exchange

• No additional infused liquids

• Weaknesses:

• Requires constant monitoring of patient temperature

• Requires extra pressure sensor

Constraints

• Economic:

• Costly manufacture

• Small market (~1000/year)

• Regulatory:

• Priming volume

• Biocompatible materials

Testing Requirements

• FDA Requirements:

• Preparation for Testing

• Biological Compatibility

Tests

• Physical Integrity Tests

• Performance

Characterization

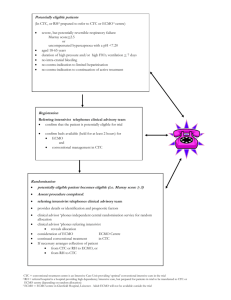

Projected Methods

• Simulate a patient using a 2.5 - 5.0 L carboy

• Utilizing a full ECMO circuit

• Additional heat exchanger used for metabolic effects

• Temperature set at 37 °C

• Record heat exchange, water and blood-side pressure drops

• Perform several 6 hour trials at various water and blood flow rates

• Also test for blood damage

Acknowledgements

• Dr. Carcillo

• Mark

• Children’s perfusionists