Modeling for Drilling Bits Interaction in Drilling Simulator Musabikhin

advertisement

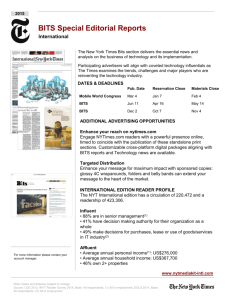

Modeling for Drilling Bits Interaction in Drilling Simulator Musabikhin#1 # Department of Electrical Engineering, School of Electrical Engineering and Informatics, Bandung Institute of Technology Bandung, West Java, Indonesia 1mbikhin@yahoo.co.id Abstract - Drilling Simulator is a computer application that was developed to describe the behavior and the process of drilling oil wells carried out in the field. This study aims to make design patterns of interaction between the drill bits with the rock formations in accordance with the suggested mathematical model. Designing the interaction model of the destruction of the rock formation using a different equation for soft to medium rock formations, and for the hard rock formations. While the interaction using the equation denudation bits added to the estimated age of bits after bits are used at certain depths. Performed on the data manipulation interaction model so obtained rate of penetration (ROP) in meters/hour, and the drilling depth as its output. In the interaction model was also conducted manipulation denudation bits, so we get bits denudation rate. The test results obtained describe the magnitude and speed of deforestation bits ROP models with field data, test results with the help of MATLAB software. Some quantities can still be derived from the interaction of other support systems are more complex. This condition can be used as a basis for further development of the simulator. Keywords: drilling simulator, rock formations, bits, rate of penetration, rate of deforestation bits. I. INTRODUCTION Based on this background, the research was conducted with the aim to design and implement interacting modeling bits with a layer of rock at the drilling simulator, the system development methodology in general through a needs analysis and review of literature, design, and implementation and testing. II. BASIS OF THEORY Computer simulation or a computational model is a computer program, or computer network, which tries to simulate an abstract model of a particular system. Simulation can be used to explore and gain new insights related to the understanding of a system that occurs [9]. Petroleum is a fossil fuel formed in the process of millions of years ago. Petroleum required to fuel the engine, motor vehicles, household fuels, as well as raw materials in chemical industry. To get the oil to do the exploration and exploitation of oil resources both onshore or offshore. A. Bits Classification The process of drilling the wells drilling include some important parts such as drilling rig, hoisting system, circulating system, rotary system, well control system, monitoring well system. The process of drilling is one of the important steps made in the petroleum industry, in addition to the exploitation stage. This process is costly, and a relatively long time, so it is lost if this process fails to do well. In the rotary system are an important component of the so-called drilling bits or drill bits. There are 2 types of rotary drilling bits, as follows. In studying the process of drilling needed to describe the process of media that can be designed in a simple and can be applied quickly, and describes all phases of the drilling process. Drilling Simulator is offered as a medium that can describe the drilling process. 1. Roller-cone bits[4] or rolling cutter bits[1]. Commonly used in drilling various types of formations, from the softest to the loudest, with a milled tooth type bits are commonly used in soft formations, and tungsten carbide inserts bits (TCI) which is used in a wider formations, including the formation of the loudest and highly abrasive formations. 2. Fixed-cutter bits[4] or drag bits[1]. Used in the drilling of the various types of formations at various depths. Drilling by drag bits are cutting the ground from the bottom of the borehole as a farmer plowing a field to make a water channel. Include polycrystalline diamond (PCD), impregnated bits and diamond bits. To classify the bits from many manufacturers, the International Association of Drilling Contractors (IADC) made good on the classification of rolling cutter bits and drag bits on. IADC makes the classification of rolling cutter bits by using a combination of three digit numbers, with the classification as detailed in the following table. Table 1. Type of bits in IADC standard. Digit 1 1 2 3 4 5 6 7 8 Digit 2 1 2 3 4 Digit 3 1 2 3 Type of bits Steel tooth bits 4 5 6 7 TCI 3. Gauge wear level. Gauge wear levels are also identified with the same gauge as tooth wear with the code G1 to G8. III. ANALISIS DAN PERANCANGAN INTERAKSI A. System Specifications Specification of a system built in the design of this study was to build a simulator application that is one of the media evaluation drilling activities in order to get the calculation of the performance of the system economically and efficiently. Here is a system and sub systems of drilling simulator applications. Information Soft medium hard Soft Soft-medium medium hard Very hard B. Destruction Stone Mechanism Interaction bits of rock formations causing the destruction of the formation so that the resulting hole with a certain depth. On the other hand these interactions also lead to the erosion of the teeth bits. 1. 2. 3. 4. 5. 2. Bearing wear level. Bearing wear levels are also identified with the same bearing as tooth wear with the code B1 to B8. Includes destruction of the basic bits [1]: wedging scraping and grinding erosion by fluid jet action percussion or crushing torsion or twisting C. Selection and Evaluation of Bits Bits that have been used can be selected and evaluated by three categories[1]. 1. Tooth wear levels. Identified with the level of T1 to T8 as shown in Figure 1 shows the calculated reduction in the use jagged bits eighths. Eg bit with T4 means the use of achieve 4/8 or 0.5. Figure 1. Tooth wear level. Drilling Simulator Formation Simulation Bits Simulation Fluid Simulation Figure 2. Drilling application system simulator. In order to produce a good application and system specifications, first made a list of requirements that need to be met by this application. Needs basis determined by reference to the following. Usability Functionally, namely to support the process of drilling in the field, these simulations must be able to provide additional information about the activity in the hole drilling bits for the user. The user experience This simulator is expected to provide a special experience for the user when to use it as a medium of learning, or performance evaluation in the field. With interactivity on simulation capability is expected to meet those needs. Under field conditions, requirements in the design of mathematical models to simulate the situation. It takes manipulation variable, and constant variables to get a response variable. The terms of the required related to these variables is as follows. 1. Data of rock formations to be explored. Data on the rock formations are distinguished 3 kinds of soil layers based on the uniaxial compressive strength (UCS), and the value of factor of rock (RF), namely a. layer of soft soil, in the form of shale rock with UCS 70 MPa, and RF 135. C. Reference Model on the Interaction of Mathematics and Rock Bits b. soil medium, a limestone rock with UCS 125 MPa, and RF 100. Influence on the destruction of rock bits are usually expressed in terms of penetration rate, rate of penetration (ROP), drilling rate or other terms relating to the progress of drilling. Some researchers try to connect the penetration rate with some rock properties are easily measured. c. hard rock, a sandstone rock with UCS 200 MPa, and RF 80. 2. Type the required bits. Bits are used according to the rock formations to be explored is the rolling cutter bits specified in the standard specification IADC code, namely the type 4-1-2, 5-1-2, and 6-1-2. 3. Rotational speed of bits. Rotational speed of bits can be set between 0 to 150 rpm. 4. Bits weight. Bits weight, or bits on weight (BOW) is set on two alternative input for 4x103 lb / in and 6x103 lb / in or equal to 71.43 kg / mm and 107.15 kg / mm. 5. Rate of tooth wear (average age of the jagged bits). Age of bits expressed in units of time (hours) according to the type bits are used in certain rock layers. 6. Penetration rate or Rate of Penetration (ROP) which is an average penetration of bits of the formation. ROP obtained from equation Calder and Workman for drilling in soft and medium layer, and the similarities Bauer on the hard layer. B. Flow Chart of Drilling Simulator Model Bits groove interaction model can be described as in Figure 3 below. Bauer equation Bauer modify equation penetration rate (ROP) as follows 𝑊 𝑁 𝑑 300 𝑃 = (61 − 28𝑙𝑜𝑔𝑆𝑐 ) ( ) ( ) … (1) with 𝑃 = Penetration rate (ft/hr) 𝑁 = rotation speed (RPM) 𝑆𝑐 = UCS (uniaxial compressive strength) in 1000 lb/in2 𝑊 = bits weight in 1000 lb. 𝑑 = bits diameter (in) Above equation can describe good results when drilling conducted on the hard rock, but it will happen aberration results when used in the drilling of rocks with a small value of UCS 2. Calder and Workman equation 𝑃 = 5,7𝑥10−5 (𝑅𝐹 − 28 log(0,145 𝑆𝑐 ))𝑊𝑁 … (2) with 𝑃 = penetration rate (m/hr) 𝑅𝐹 = rock penetration factor 𝑆𝑐 = UCS (MPa) 𝑊 = bits weight (kg/mm) N = rotation speed bits (RPM) Mulai Input: t, BOW, RPM, tipe bits T ROP Calder Workman D. Destruction Testing of Rock Y ROP Bauer Input data in accordance with the needs analysis, ROP obtained on three different rock layers as follows. Hitung kedalaman pengeboran T 1. Calder dan Workman[3] recommends penetration rate equations in a layer of rock with low UCS values as follows 7. Constants associated with the drilling. Apakah lapisan batuan keras? In the interaction model used estimates of drilling simulator ROP measurements using multiple equations as follows. Apakah penggundulan bits > 6/8? Y Selesai Figure 3. Flowchart model. Table 2. ROP in several layers of rock conditions. Type of formation W/d (kg/mm) N (rpm) ROP (m/hr) Shale 71.43 80 34.79 100 Limestone 80 Sandstone 80 107,15 80 80 Testing the influence of the length of the serrations of the denudation rate relative to the results of testing bits in the range of values 0.1 to 0.5 (the jagged bits long) produces the graph shown in Figure 5 below. 8,13 65,24 31,65 100 Sandstone 26,37 52,19 100 Limestone E. Destruction of Bits 6,50 100 Shale 43,49 21.10 100 From the graph Figure 4 above, can be interpreted to mean that the value of ROP decreases exponentially increasing in line with UCS. This means that the rocks have high compressiv longer be penetrated and destroyed by the bits of rock that is more than soft. 80 39,56 9,75 100 12,19 If we assume the thickness of each layer of rock is 40 m, the drilling time required are listed in Table 3 below Figure 5. Charts the influence of jagged bits long Table 3. Time of drilling at a depth of 40m. Type of rock Shale ROP (m/jam) 34.79 43,49 Limestone 21.10 Sandstone 6,50 Shale 52,19 26,37 8,13 65,24 Limestone 31,65 Sandstone 9,75 39,56 12,19 Drilling time (jam) 1,15 0,92 1,90 1,52 6,15 4,92 0,77 0,61 1,26 1,01 4,10 3,28 Penetration rate (ROP) on the type of formation is very different depending on the specific value of the uniaxial compressive rock strength (UCS), which influences the magnitude of the ROP UCS can be described on a graph as in Figure 4 below. Figure 4. Charts the influence of UCS on ROP. From Figure 5 it can be concluded that the rate of deforestation relative bits decreases with the initial length jagged bits. The longer the initial size of the jagged bits, the smaller the relative speed of the denudation bits. Testing the influence of weight bits of bits denudation rate relative to the results of testing on a range of values 1 through 9 produces the graph shown in Figure 6 below Figure 6. Charts the influence of weight per-diameter bits. Testing the influence of rotation speed to the speed of deforestation bits bits represented by the test results relative to the range of values of 70 rpm to 120 rpm produces a graph as shown in Figure 7 below. Figure 7. Charts the influence of rotation speed bits. From the test results on the mathematical model, it shows the same results with the simulation on the simulator, and together with the results of field data with the same conditions. IV. CONCLUSIONS AND RECOMMENDATIONS A. Conclusion 1. The simulator can model the destruction of rocks by a mathematical model equations Calder and Workman on a rock with low UCS, and Bauer equations on a high rock with UCS. 2. Interaction also leads to bits of rock bits that are affected by desertification have long jagged bits at first, bits weight, round bits. B. Suggestion 1. Test patterns of interaction with rock bits can be closer to real conditions in the field, if there is data drilling results are more specific and detailed. So it takes the actual data that can only be obtained from the drilling field. 2. Applications can be further related to the setting pipe, drill colar, and the connection that exists in the drill stem, and other parameters related to drilling, so that the simulator generates a more complex and closer to the actual conditions. REFERENSI [1] Bourgoyne, Adam T. Jr, Applied Drilling Engineering, Society of Petroleum Engineers Richardson, TX, 1991 [2] Darley, H.C.H, Gray George R., Composition and Properties of Drilling and Completion Fluids, Fifth Edition, Gulf Publishing Company, Houston, 1988. [3] Gokhale, Bhalchandra V., Rotary Drilling and Blasting in Large Surface Mines, Taylor & Francis Group, London, UK, 2011. [4] Lake, Larry W., Petroleum Engineering Handbook, Society of Petroleum Engineers USA, 2006. [5] Lyons, William C., Standard handbook of petroleum and natural gas engineering, Gulf Publishing Company, Houston, Texas ,1996. [6] Lyons, William C., Working Guide to Drilling Equipment and Operations, Gulf Publishing, Burlington, 2010. [7] Moore, Preston L, Driling Practice Manual, Penn Well Publishing Company, Second edition, Oklahoma, 1986. [8] Prassl Wolfgang F. Drilling Engineering, Departement of Petroleum Engineering, Curtin University of Technology. [9] Robinson Stewart, Simulation: The Practise of Model Development and Use, John Wiley & Sons Ltd, West Sussex, 2004. [10] Selley Richard C., Elements of Petroleum Geology, Academic Press An Imprint of Elsevier, Second Edition, California, 1998. [11] Sridadi, Bambang, Pemodelan dan Simulasi Sistem. Teori, Aplikasi, dan Contoh Program dalam Bahasa C, Informatika Bandung, 2009.