Workplace Safety

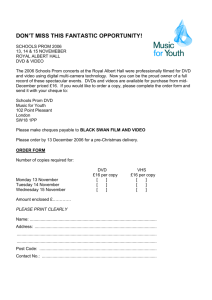

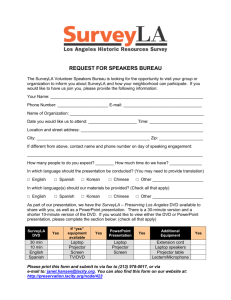

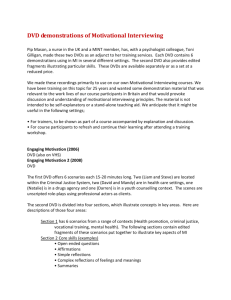

advertisement