Production of Biodiesel

advertisement

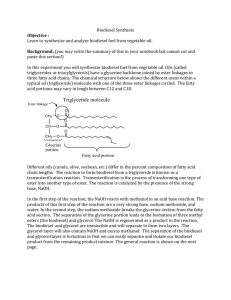

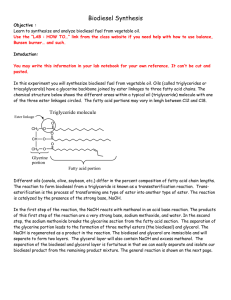

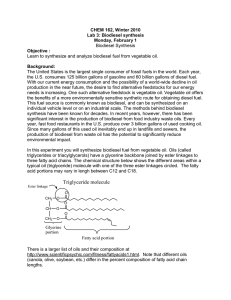

Production of Biodiesel Diesel versus Biodiesel Diesel • Petroleum product (Petra = rock; oleum = oil) • Made from crude oil which takes millions of years to form • Non-renewable resource Biodiesel • Can be made from vegetable oils and animal fats • Most commonly made from soybean and canola oil, vegetable crops that can be grown annually • Can be made from waste oils and greases (from fryers of restaurants and factories) • Renewable resource How is biodiesel made? • Primary source of biodiesel is vegetable oil • Most plant oils and animal fats are triglycerides How is biodiesel made? continued • Reaction of transesterification Other name: methyl alcohol Base catalyst is a strong base potassium hydroxide which is reacted to methanol to form methoxide. How is biodiesel made? continued • Heat is also necessary to speed up the reaction • The fatty acid tails are removed from the glycerol in the oils • They are converted into esters (biodiesel) Lab Objectives • Perform a transesterification on a triglyceride (oil) to separate glycerol and fatty acids. • Use a two phase process to increase conversion of vegetable oil to biodiesel • Observe the differences in burning properties between biodiesel and vegetable oil. Safety First • Gloves • Goggles • Lab apron CHEMICALS ARE CORROSIVE (CAN CAUSE BURN). CAUTION AROUND HOT PLATES PART OF YOUR GRADE WILL BE ON HOW YOU CAN FOLLOW SAFETY. Materials • 2 100 ml beakers • Graduated cylinder 100 ml • graduated cylinder 10 ml • Thermometer • Transfer pipettes • Stirring rod • 12.5 ml Methyl alcohol • timer Materials shared • • • • vegetable oil potassium hydroxide Electronic balance Hot plate Making crude biodiesel – two phase process • Methoxide preparation: mixing methanol with potassium hydroxide (steps 1 to 7) • Phase 1 transesterification: react the oil with methoxide while heating to produce biodiesel esters and glycerol (steps 8 to 16) • Phase 2 transesterification: convert any remaining triglycerides (oil) into biodiesel (steps 17 to 21) Pre-lab: Procedure reading comprehension • While reading the procedures 1 to 21: – Put a box around amounts/ grams or volumes/ml of chemicals. – Underline action verbs/phrase – Put a circle around times and temperature. – Draw the safety triangle symbol whenever there is safety issue. Example: 1. using an electronic balance, weigh out 0.6 g of potassium hydroxide. Continue shaking in 60 seconds increments. Heat the oil to 55-60°C. Pre-lab: procedure flowchart • Take the underlined, boxed, and circled information and put it into a flowchart. • Add illustrations to your flowchart