Auger electrons

advertisement

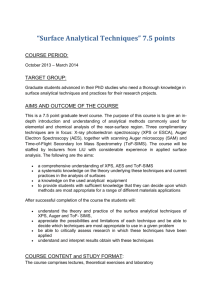

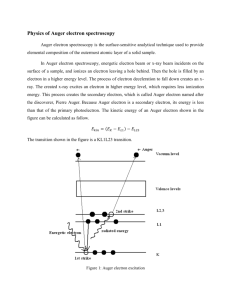

Methods and Tehniques in Surface Science Prof. Dumitru LUCA “Alexandru Ion Cuza” University, Iasi, Romania Outline • Auger Electron Spectroscopy (AES) – short historic and physical background, • How AES measurements are performed, • Information derived from Auger spectra: • Methodology • Data analysis • Experimental considerations Short historic of the Auger spectroscopy • Pierre Auger, in 1925 observed (at first in the cloud chamber, then in photographic plates) the occurrence of electrons with precisely determined energies. These electrons have been later named Auger electrons) may serve to identify their parent atoms. 1953 J. J. Lander – the idea of using the Auger electrons in surface analysis.. Pierre Auger • The AES has been implemented as an analytic tool in 1967 (Larry Harris), after increasing the method sensitivity by using differential spectra to discriminate the tiny Auger peaks in the electronic spectra. • 1968 – Auger spectrometer with CMA in modern configuration. • Beam current as low as 1 nA • Probing depth: 0.5 - 10 nm, and < 10 nm lateral resolution(!!!) Nowadays: • Covering a wide range of elements which can be detected (except for H and He). • High sensitivity: 100 ppm for most of the elements. Auger spectra. Expanation of the Auger effect in free atoms 1. The occurrence of an electron vacancy in a core level (K, L) (core level), by incident electron, X – ray photons, or ions. Little information is available for the energy of the primary and ejected electrons, due to complex cascade of successive collisions with the matrix. Therefore the complex picture in Fig. 1 2. The vacancy is filled by a second electron coming from an upper energy level. 3. The energy of the emitted electron can serve for: - the emission of a X photon (Z > 30) - ejection of a 3-rd (Auger) electron via a non-radiative process. 4. The net result: an atom in a double-ionized state + 2 emitted electrons emisi (the K core level electron and the Auger electron). Auger transition nomenclature Auger electron Labelling: KL1L2 AVV Incident electron The 3 letters specify the energy levels implied in the process of emission of the Auger electrons KE = EK-EL1-E*L2- j, EK, EL1, and EL2 – the energy levels mentioned in the labeling (generally different from the neutral atom, due to the presence of electron vacancies). Factors influencing the Auger peak area 3keV incident 1. Ionisation cross section electron beam LMM KLL 10 keV incident electron beam MNN Factors influencing the Auger peak area (cont’d) 2. The Auger yield • Competition between the Auger process and the X-ray fluorescence. • The probability of occurrence of the Auger electrons increases with the decreasing of the differences between the energy levels involved in such transitions. 3. Backscattering Auger electron spectra 1. Direct spectrum Electrons in the Auger spectra have energy values between 280 eV (KLL, Zn) si 2100 eV (S). Example: The KL1L2 transtion of Si occurs at the energy of 1600 eV (since the difference between the energies of L1 and K levels for Si is1690 eV, while the difference between L1 and L2 levels is 90 eV). Auger spectrum Kinetic Energy The tiny Auger peaks are difficult to process. They become visible after 10 x magnification. After L1 → K de-excitation either an X-ray photon (Ka of Si), or an Auger electron may be emitted having energy of approx. 1690 – 90 = 1600 eV. Auger electron spectra 2. Differential spectrum More features of the spectra occur clearly in the dN(E)/dE vs. K.E. Even more features occur in the d[E*N(E)]/dE vs. KE plots. This is the most used kind of Auger electron spectrum. Auger spectra of light elements (the y-axis differs for different elements) AES sensitivity • Electrons emitted in the solid will “escape” in vacuum if they are not inelastically scattered. • The scattered electrons vill have energies less energy than Auger electrons, thus they will occur in the “tail” of the spectrum, towards smaller KE values, along with secondary electrons. • Many electrons will fully lose their energy via inelatic collisions in the solid. • Therefore, only Auger electrons originating in the surface region (which did not experience inelastic scattering) will be collected by the analyser. I out I 0 e d MNN 3 0 0 Background Auger electrons x e dx x e dx 1 e3 0.95 1 95% of the electrons leaving the surface originate in a layer 3 depth. Experimental arrangement Instrumentation Electron gun Electron detector Cylindrical mirror analyser (CMA) • UHV chamber • Specimen import unit • Electronics • Computer and software Specimen Scanning Auger Microscopy (SAM) AES Auger Electron Spectroscopy SAM Scanning Auger Microscopy: Same instrument can provide SEM imaging, Auger spectra and chemical Auger mapping. Applications • 1keV incident electron beam → penetration depth of about 15 Å. Focussing & scanning system of the incident e-beam • Verification of surface contamination freshly prepared in UHV. • Investigation of the thin film growth process + elemental analysis. • Depth profiling of concentration of chemical elements. Specimen Qualitative analysis Elemental identification procedure 1. First, the main Auger peak positions are identified. 2. These values are correlated with the listed values in the Auger spectra book or standard tables. The main chemical elements are thus identified. 3. The identified element and transition are labelled in the spectrum (close to the negative jump in the differential spectrum). 4. The procedure is repeated for so-far unidentified peaks. E0 = 3keV The Auger spectrum of a sample under investigation Qualitative analysis Example: From the differential AES spectrum Ni, Fe and Cr have been identified. Ni Fe Cr Information concerning chemical composition • Peak shape and the energy values, corresponding to maxima contain information on the nature of the environment, due to addition relaxation effects during the Auger process • A full theoretical model is difficult to construct. • In practice, Auger spectra of standard samples are used and the results are drawn from spectra comparison. SAM SEM surface image SAM image: red =Al; blue = F; magenta = Al + F Al+F+O Red = Al; green = O red =Al; blue = F; green = O SEM and Auger images of an aluminium oxide surface, in absence and presence of fluorine contramination. Quntitative analysis dEN(E)/dE vs. E 1. Measuring the peak-to-peak height N(E) vs. E 2. Measuring the peak area (after background subtraction) Factors affecting the peak intensity For a homogeneous sample, the Auger peak intensity is given by: I i I P Ni i i (1 r ) cos F T D R Ii: Intensity of the detected current, due to the ABC Auger transition of the i element, IP: Incident beam current, Ni: Concentration of the element i in the surafce, i: Ionization cross-section on the A-level of the element i by the electrons from the incident beam, i: Probability of the Auger ABC transition of the element i, r: ionization cross-section on the A-level of the element i by the electrons scattered in previous processes, : mean free path for inelastic collisions, : incidence angle of the primary beam, F: Correction factor, dependent on the entrance solid angle in the analyzer, T: Transfer function of the analyzer, D: Detection efficiency, R: Roughness factor of the surface. Remarks 1. Deriving Ni from the previous equation is rather difficult, due to large number of implied parameters, 2. In applications, empirical methods are used, which leave from: (a) utilization of standard specimens; (b) utilization of sensitivity factors. Quantitative analysis using standard specimens Advantages: No need to know “obscure” physical quantities: • ionization cross-section, i on the A-level of the element i by the electrons in the primary beam, • the Auger yield, • backscattering cross-section and electron escape depth values. Drawbacks: • Necessity to prepare standard samples, • Valid only for homogeneous samples, • Quite low accuracy. Quantitative analysis using sensitivity factors • Measurements are done under the same conditions on standard samples to cancel the correction factors, associated to the set-up particularities: I pur Ix N x S x N pur S pur Sensitivity factors, Si, have been measured for certain energy values of the electrons in the primary beam. They are tabulated for all the chemical elements. • The atomic concentration of the elment a in the sample with N elements can be derived using the equation: Xa Na Ni i 1.. N I a / Sa I i / Si () i 1.. N The method is semi-quantitative, since the back-scattering effects and the escape depth of the electrons are negliged. Drawbacks of empirical methods They do not include the so-called matrix effect of the sample: the inelastic mean free path (), the back-scattering factor (r), chemical effects on the peak shape in the Auger spectra, effect of the surface roughness. All these drawbacks result in errors of about 15%. The errors can be diminished to 1% by using standard samples with the same matrix, to derive Si. Fe Example Cr Ni Peak-to-peak height: Fe Cr @ 529eV: Fe @ 703eV: Ni @ 848eV: 4.7 10.1 1.5 Si 0.32 0.20 0.27