Manufacture - Turbo Team

advertisement

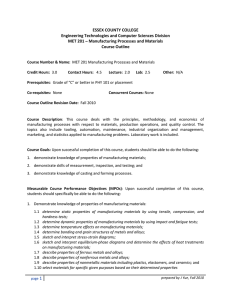

Chapter 1 General Introduction 1 DEPARTMENT OF INDUSTRIAL ENG. Manufacturing Process I FACULTY: Dr. Mazin Obaidat e-mail: mazin@hu.edu.jo, Room: 3079 Office Hours: 12:00-1:00 (Mo.,We.).. TEXTBOOKS: • Manufacturing Processes for Engineering Materials, Serope Kalpakjian and Steven R. Schmid, Prentice Hall, 5th Edition, 2008 • Fundamentals of Modern Manufacturing – materials, processes and systems, Mikell P. Groover, Wiley, 2nd Edition, 2002 References: 1. 2. 3. Materials and Processes in Manufacturing, E. Degarmo, J.T. Black and R.A. Kohser, Wiley, 9th Edition, 2002. Mechanical Metallurgy, G.E. Dieter, McGraw-Hill, 3rd Edition, 1986 Material Science and Engineering, W.D. Callister, 6th Edition, Wiley, 2002 Manufacturing Process I Handouts: are available at Moodle http://www.mlms.hu.edu.jo/ Assessment1: First Exam Second Exam Others Final Exams: Assessment3: Mid Exam Project Others Final Exams: Assessment2: 25 % First Exam 25 % Second Exam 10% Final Exams: 50 % 20% 20 % 20% 50 % 30 % 30 % 40 % Course Outline • Introduction to Mechanical Shaping •Review of Mechanical Properties • Annealing – Recrystallization • Forming Process Variables - hot, warm or cold forming • Bulk Deformation: Rolling, Forging, Extrusion, Drawing • Sheet metalworking: •Bending, •Shearing, •Deep drawing •Material Removal: Machining, Cutting Tools • Powder Metallurgy What is Manufacturing? Manufacture is derived from two Latin words manus (hand) and factus (make); the combination means “made by hand” “Manufacture” was first coined around 1567 A.D. Made by hand???!!! What about the Modern Manufacturing? For our purposes, manufacturing means production of hardware, which ranges from nuts and bolts to digital computers and military weapons, as well as plastic and ceramic products Manufacturing is Important Historically To a significant degree, the history of civilization is the history of humans' ability to make things Historically, the importance of manufacturing in the development of civilization is usually underestimated • Throughout history, human cultures that were better at making things were more successful • Making better tools meant better crafts & weapons – Better crafts allowed the people to live better – Better weapons allowed them to conquer other cultures in times of conflict Manufacturing Processes Manufacturing adds value to the material by changing its shape or properties, or by combining it with other materials that have been similarly altered So, a manufacturing plant consists of a set of processes and systems (and, of course, people) designed to transform a certain limited range of materials into products of increased value System Process Materials Modern Manufacturing There is a strong interdependency among these three building blocks. Manufacturing Manufacturing can be defined in two ways: Technologically Economically 8 Technologically? Technologically manufacturing means: is the application of physical and chemical processes to alter the geometry and appearance of the given starting material to make product or part 9 Economically Economically: manufacturing is the transformation of materials into items of greater value by means of one or more processing or assembly operations. Examples: 1.When iron core is converted into steel – value is added 2.When sand is transferred into glass-value added 3.When petroleum is refined into plastic-value is added 10 What is Manufacturing? It is the process of converting the raw materials into products. Also it involves activities in which the manufactured product itself is used to make other products. Products are: 1. Discrete: nails, gears, etc. 2. Continuous: sheet metal, tubes, hose, wire, etc. 11 Manufacturing capability Manufacturing capability refers to the technical and physical limitations of any manufacturing firm We can identify several dimensions of this capability: Technological processing capability Physical product limitations Production capacity. 12 Manufacturing capability Technological processing capability: it’s the available set of manufacturing process Examples: Certain plants or firm performing machining operations, others roll steel sheet, casting, forging…. Machine job can not produce car. 13 Manufacturing capability Physical product limitations: one of the most important thing that identify the capability of firm is the weight and size of product. Examples: Large and heavy products are difficult to move, to move these products the firm must be equipped with cranes of required load. Smaller parts and products made in large quantities can be moved by conveyer or other means. 14 Manufacturing capability Production capacity: is the production quantity that can be produced in a given time (e.g. month, or year). Plant capacity: maximum rate of production the company can a achieve under assumed operations conditions. Shift per hours Direct labors. 15 Type of Production Mass Production: the manufacturing of large quantities of standardized products utilizing assembly line technology such as mass production of airline and automobile using special purpose machines. The concepts of mass production are applied to various kinds of products to assemblies of such parts such automobile . (over 100,000 piece/year) Batch Production: refer to a method of manufacturing where several of the same item are put together at the same time. [ is a technique used in manufacturing, in which the object in question is created stage by stage over a series of workstations, and different batches of products are made] Batch production is most common in bakeries and in the manufacture of sports shoes, pharmaceutical 16 ingredients 100-5000 piece/year Type of Production Job Shop Production: sometimes called jobbing or one-off production, involves producing custom work, such as a one-off product for a specific customer using general purpose machines (making railings for a specific house, building/repairing a computer for a specific customer, making flower arrangements for a specific wedding etc.) (10-100 piece/year) 17 Product Design Process It is the process where the product is passing through many steps, from the first step (conceptual design) till its manufacturing (product) 18 Product Design Process Figure I.4 (a) Chart showing the various steps involved in design and manufacturing a product. Depending on the complexity of the product and the type of materials used, the time span between the original concept and the marketing of the product may range from a few months to many years. 19 Important Considerations Product Design Process Flexible production methods Computer integration Productivity 20 Important Considerations Product Design Process Design requirements, Ex: baseball bat Bat less 1.5 bound Made out of approved material Able to hit baseball without breaking Manufactured by environmentally friendly and economical methods Quality inspection at each stage. 21 Important Considerations-Product Design Process Manufactured by environmentally friendly and economical methods. Consider the effects of water and air pollution, acid rain, ozone depletion, hazardous waste, and global warming. The adverse effects of these activities, their damage to our environment and to earth ecosystem, ultimately, their effect on the quality of human life are now well recognized by the public as well as by the governments. In response, a wide range of laws and regulations have been promulgated by governments. These regulations are generally stringent, and their implementation can have a major impact on the economic operation of manufacturing . These efforts have been most successful when there is value added, such as in reducing energy requirements ( associated cost) that have both cost and environmental design benefits. 22 Important Considerations Product Design Process Much progress has also taken place regarding 1. Design for recycling 2. Design for environment (DFE) or green design These comprehensive approaches anticipate the possible negative environmental impact of materials, products, and process so that they can be considered at the earliest stages of design and production. 23 Important Considerations-Product Design Process Other developments such as sustainable manufacturing and cardleto-cardle philosophy. 1. Sustainable manufacturing : which refers to the realization that natural resources are vital to become economic activity, to ensure that resources are available for future generations. 2. cardle-to-cardle philosophy. A philosophy that encourages the use of environmentally friendly materials and design Environmentally friendly materials can be: Part of a biological cycle, where usually organic materials (such as wood, and polymers) are used in the design, function probably for their intended life and can then be disposed of. Such materials degrade (dissolve) naturally, and in the simple version, lead to new soil that can sustain life Part of industrial cycle, such as aluminum in beverage containers that serve an intended purpose and are then recycled, so that the same material is reused continuously. 24 Design Principles for Economic Production 1. Designs should be as simple as possible to manufacture, assemble, disassemble, service, and recycle. 2. Appropriate Material [ material should be chosen for their appropriate design and manufacturing characteristics as well as for their service life]. 3. Dimensional accuracy. 4. Finishing should be avoided or minimized.[because they can add significantly to 25 the cost] Redesign of Parts Figure I.5 Redesign of parts to facilitate assembly. Source: Reprinted from G. Boothroyd and P. Dewhurst, Product Design for Assembly, 1989. Courtesy of Marcel Dekker, Inc. 26 Selecting Materials A wide variety of materials is now a available, each having its own characteristics Composition Applications Costs Advantages And limitations 27 Selecting Materials Many factors have to be considered when selecting possible materials to fit a design and manufacturing requirement: Dose the material posses the necessary mechanical, electrical and thermal properties? Can the material be formed to the desired shape? Will the properties of the material alter with time during service? Will the material adversely affected by the environmental conditions and resist corrosion and other forms of attack? Will the material be acceptable on aesthetic grounds? Will the material give sufficient degree of reliability and quality? And, of course: Can the product be made at an acceptable cost? 28 Classification of engineering materials Engineering materials can be classified into two or three classifications: 1. Metallic: Ferrous: (iron, steel, cast iron, wrought iron) Non ferrous(Al its alloys, Cu its alloys, Mg its alloys 2. Non Metallic. Organic (polymers, wood) Inorganic(ceramic, glasses) Matrix polymer Reinforcement fiber glass 3. Composite materials ????? Metal matrix composite Ceramic matrix composite Polymer matrix composite 29 Composite materials 30 Alloys versus composite • Composite materials: concrete Matrix consists of two materials or more, each material has a surface that separate it from the other materials • Alloys: is a mixture of two materials or more showing metallic properties such as Brass (Cu+Zn), Bronze (Cu+Sn) Reinforcement iron bar A+B material Grain boundaries 31 Classes of Materials There are 3 major classes: 1. Metals Usually alloys, which are composed of two or more elements, at least one of which is metallic Two basic groups: a. Ferrous metals - based on iron, comprise 75% of metal tonnage in the world: • Steel = iron-carbon alloy with 0.02 to 2.11% C • Cast iron = alloy with 2% to 4% C b. Nonferrous metals - all other metallic elements and their alloys: aluminum, copper, gold, magnesium, nickel, silver, tin, titanium, etc. Classification of engineering materials • Steel : is iron and carbon, theoretically the % of carbon in steel less than 2%, practically the % of carbon in steel no more than 1.6% • Type of steel High carbon steel( doesn't exceed =1.6%) Mild carbon steel( 1.3% < Carbon% <1.6%) Low carbon steel(= 1.3% of carbon). • We add carbon to iron to become steel in order to increase hardness 33 Classes of Materials 2. Polymers A compound formed of repeating structural units called mers, whose atoms share electrons to form very large molecules Three categories: 1. Thermoplastic polymers - can be subjected to multiple heating and cooling cycles without altering their molecular structure 2. Thermosetting polymers - molecules chemically transform (cure) into a rigid structure upon cooling from a heated plastic condition 3. Elastomers - exhibit significant elastic behavior Classes of Materials 3. Ceramics A ceramic is an inorganic, nonmetallic solid material comprising metal, nonmetal or metalloid atoms primarily held in ionic and covalent bonds. The crystallinity of ceramic materials ranges from highly oriented to semi-crystalline, and often completely amorphous (e.g.,glasses) - Molecules based on bonding between metallic and non-metallic elements (including oxides, nitrides, carbides) - Typically insulating and refractory Sub-Classes of Materials metalloid is a chemical element with properties in between,of metals and nonmetals Such Si and B Semiconductors (ceramics) Intermediate electrical properties Composites (all three classes) Combinations Bio Materials (all three major classes) Materials compatible with body tissue Selecting Materials Why do we study materials? Many engineers, whether mechanical, civil, chemical, electrical or mechatronics will be exposed to design problem, and the reason for this design problem is selecting the material. Ex: transmission gear, the superstructure for building or an integrated circuit board. Always the problem is not selecting the right material for the right application. 36 Criteria to select the proper material Service conditions must be characterized. In rare occasions dose the material posses the ideal combination of properties- trade off one characteristic for another. Ex: a material having a high strength will have a limited ductility. In such case a reasonable compromise between two or more properties may be necessary. 37 Criteria to select the proper material Deterioration of material properties that may occur during operation service. A significant reduction in mechanical strength may result from exposure to elevated temperature. The economics. What will the finished product cost? A material may be found that has the ideal set of properties, but still expensive compromise is still necessary. 38 Important Considerations selecting materials Very many properties of materials have to be considered when choosing a material to meet a design requirement. These include a wide range of physical, chemical and mechanical properties together with forming, or manufacturing characteristics, cost and availability and, in addition, more subjective aesthetic qualities such as appearance and texture. 39 Important Considerations selecting materials Properties of Materials – – – – Mechanical properties Physical properties Chemical properties Manufacturing properties Cost versus availability Service life and recycling Operational cost : Fixed cost : overhead cost (oil, water, electric..) Variable cost: cost of material, this cost vary according to how much product is produced. 40 Properties of materials Mechanical properties [strength, ductility, toughness, hardness, elasticity, and creep….] • These properties can significantly modified by various heat treatment methods. • So the mechanical properties should be appropriate for the conditions under which the product is expected to function. Physical properties [density, melting point, thermal expansion, thermal conductivity and electrical and magnetic properties, also need to be considered]. 41 Properties of materials Chemical properties [ resistance to corrosion, resistance to oxidation] Also can play a significant role in hostile as well as normal environment. Oxidation, corrosion and flammability of the materials are among the important factors to be considered, as is toxicity (lead-free solders) Manufacturing properties determine weather the material can be processed [ machinability, formability, castability, weldability] with relative ease. The methods used to process materials to the desired shapes should not adversely affect the product’s final properties and service life 42 Machinability versus formability Machinability : the operation where certain a mount of the material is removed from the surface as chips. Or the ability of the material to be shaped by removing a certain a mount from the surface to reach the desired shape. Formability: it is an operation of forming the material but without removing a certain a mount from the surface, it can be done by knocking on or pulling the material and delivering in another shape [ the mass of the material before and after the process will be the same]. 43 Properties of materials Cost versus availability If raw materials are not commercially available in the desired quantities and shape, additional processing may be required; these steps can contribute significantly to product cost For example, if we need a small round bar of a certain diameter and it is not commercially available, then we have to purchase a large diameter bar and reduce its diameter, by processes such as drawing through a die or machining 44 Properties of materials Service life and recycling Time-and service are dependent phenomena such as wear, fatigue, creep, corrosion, and dimensional stability are important considerations as they can significantly affect a product's performance, and if not controlled, can lead to failure of product. The corrosion caused by compatibility of different materials used in a product is also important; an example is galvanic action between mating parts made of dissimilar metals. Recycling or proper disposal of the individual components in a product or the whole product at the end of its useful life is important as we become increasingly aware to live in clean and health environment. Toxic wastes is a also a crucial consideration and need to have 45 proper treatment and disposal Factors affecting the cost of the materials 1. Availability in the nature. 2. Concentration of the material in the ore. 3. The cost of extracting the material from the ore. 4. By products [ through extracting the material, other material can be so benefit, example extracting petroleum we have methane gas] 46 Manufacturing Characteristics of Alloys 47 Factors influencing properties and (Manufacturing) Behavior of Metals • Atomic Structures – Crystal structures: bcc, fcc, hcp – Slip, slip planes:b/a ratio, anisotropy • Imperfections – Line: dislocations (strain hardening) – Point: vacancy, interstitial (alloys, e.g. Fe-C), impurity (alloys, e.g., Al, Cu) – Volume: voids, inclusions (e.g. oxides, carbides, sulfides) – Planar: grain boundaries • Grains – Properties depend on size, large grains are softer (why?) lower strength, hardness, & high ductility and produce rough surface after stretching (orange peel example) Important Considerations: Selecting Manufacturing Processes A wide range of manufacturing processes are used to produce a variety of parts, shapes and sizes. There is usually more than one method of manufacturing a part from a given material. Each of these processes has its own advantages, limitations, production rates and cost Casting, Forming , Machining, Joining, Nanofabrication Selection of a particular manufacturing process depends not only on the component or part shape to be produced, but also on many factors such as properties of the martials. Brittle and hard materials, can not easily be shaped whereas they can be cast or machined by various method 49 Solidification Processes • Starting material is heated sufficiently to transform it into a liquid or highly plastic state • Examples: Casting for metals, molding for plastics Deformation Processes • Starting workpart is shaped by application of forces that exceed the yield strength of the material • Examples: (a) forging, (b) extrusion Material Removal Processes • Excess material removed from the starting workpiece so what remains is the desired geometry • Examples: machining such as turning, drilling, and milling; also grinding and nontraditional machining processes Particulate Processing • Starting materials are powders of metals or ceramics • Usually involves pressing and sintering, in which powders are first squeezed in a die cavity and then heated to bond the individual particles Waste in manufacturing Processes It is desirable to minimize waste and scrap in part shaping – Material removal processes tend to be wasteful in the unit operation, simply by the way they work – Casting and molding usually waste little material The Materials Selection Process Pick Application: Determine required Properties : mechanical, electrical, thermal, magnetic, optical, deteriorative. Properties: Identify candidate Material: alloys, composition. Material : Identify required Processing Processing: changes structure and overall shape ex: casting, forming, joining. 55 Near Net-shape manufacturing Because not all manufacturing operations produce finished products or products to desired specifications, additional finishing operations may be necessary. For example, a forged part may not have the desired dimensional accuracy; thus additional operations such as machining may be necessary. Likewise, it may be difficult to produce a product using only one manufacturing process, a part that, by design, has a number of holes in it, necessitating additional process such as drilling. Also, the holes produced by drilling process may not have the proper roundness, dimensional accuracy, or surface finish, thus necessitating the need for additional operations, such as honing. These additional operations can contribute significantly to the cost of a product Net-shape manufacturing Consequently, net-shape or near-net-shape manufacturing has become an important concept in which the part is made also close to the final desired dimensions, tolerances, and specifications. Terminology: Net shape processes - when most of the starting material is used and no subsequent machining is required to achieve final part geometry Near net shape processes - when minimum amount of machining is required Typical examples of near-net shape manufacturing Near-net-shape forging or casting or metal injection molding Computer Integrated Manufacturing CIM: software and hardware are integrated from product concept through product distribution in the marketplace. It has the capability of: 1. Improved responsiveness to rapid changes in market demand and product modification. 2. Better use of materials, machinery and reduction in inventory. 3. Better control of production. 4. Manufacturing high quality products at low cost. 58 Lean Production and Agile Manufacturing Lean Production Minimizing the waste in production process. Dealing with problems as soon as they appear. Agile manufacturing (flexibility): Ensuring flexibility. Respond to changes in product demand. Benchmarking: A measurement of the quality of an organization’s polices, products, strategies..., and their comparison with standard measurement. 59 The objectives of benchmarking 1. Determine what and where improvements are called 2. Analyze how other organizations achieve their high level performance. 3. Use this information to improve performance. 60 Quality Assurance and Total Quality Management QA: is a systematic process of checking to see whether the product or service developed is meeting specified requirements. Product integrity: is a term that is generally used to define the degree to which a product: is suitable for its intended purpose, responds to a real market demand, functions reliably during its life expectancy. 61 Quality Assurance and Total Quality Management TQM : A comprehensive and a structured approach that seeks to improve quality of products or service through ongoing refinement in response to continuous feed back. It must be the responsibility of everybody involved in designing, manufacturing, and marketing of a product. Experimental Design: A technique in which the factors involved in a manufacturing process and their interactions are studied simultaneously. 62 Quality Assurance and Total Quality Management Product liability: The consequences of product failure, including failures during possible misuse of products, must be fully understood by those involved with product design, manufacturing, and marketing. Human-factors engineering and ergonomics: Deals with human versus machine interactions and thus are important aspects of design and manufacture of safe products. 63 General Trends in Manufacturing: World-class Matrix High Quality Low Cost Minimum Time 64