For High Voltage Motors

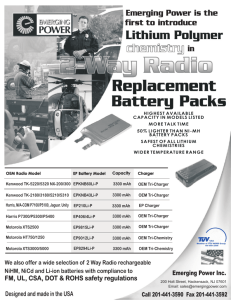

advertisement

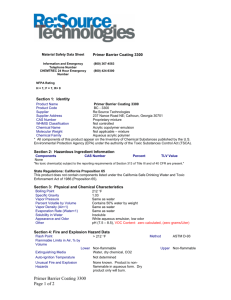

0/54 1. Introduction 1.1 CEO Greeting & Profile …………………………….. 1.2 CEO Profile …………………………………………… 1.3 HIGEN is …….…………..……………………………. 1.4 History …………………………………………………. 1.5 Overview ………………………………………………. 1.6 Product Portfolio ……………………………………. 1.7 Corporate Organization ……………………………. 1.8 HIGEN’s Customers ………………………………… 1.9 Key Clients …………………………………………… 1.10 Certificates ……….…………………………………. 1.11 Quality Assurance …………………………………. 1.12 Overseas Networks ……………………………….. 1/54 2 3 4 5 6 7 8 9 10 11 12 14 1.1 CEO Greeting Dear Customer, HIGEN MOTOR has been in motor manufacturing businesses since 1963 as a business unit of LG Group of Korea. In 2008, HIGEN MOTOR was spun off as an independent corporation specializing in motors and energy transfer solutions including products such as general AC induction motors, servo drives and servo motors, inverter motors, permanent magnet motors, spindle motors, and related products of industrial grade with power rating of 0.4 kW to 2500 kW. The main factory is located in Changwon Industrial Complex of Korea with a staff of about 270 engineers and technicians. HIGEN MOTOR is a leader of motor industry in Korea and has been supplying its products to Korea’s industrial companies, machinery manufacturers and robotics industry including POSCO, OTIS Elevator, WILO Pump , Samsung, LS and Dasa Robots. With aspiration to become a global player, we intend to step up our efforts to develop business opportunities with our prospective customers in the international market. With this aspiration we have begun to pursue our vision for Energy Transfer Solution Provider : transformation from a passive component supplier to an energy transfer solution provider specializing in the most energy efficient solution to turn electrical energy into mechanical energy for our customers in various industrial applications. We realize that achieving this aspiration is not an easy task, and yet not an impossible task if we continue to challenge with determination and spirit, the spirit of “Challenge to the World, Challenge to the Future.” In pursuit of our vision for Energy Transfer Solution Provider, we are presently expanding our export network and invite you to join our export initiative program as an importer, a distributor, a sales representative, and an end user in the industries you are familiar with. Looking back on 2013, HIGEN MOTOR was able to make significant progress in the business structure and technical capability. In the era of environment friendly electrical vehicle, the Korean government announced policy to support the Korean automobile industry to achieve annual production capacity of one million electrical vehicles by the year 2020. In pursuit of this aspiration, HIGEN MOTOR has played a pioneering role as an EV motor manufacturer carrying the ball in the power train sector of Korean electrical vehicles industry exporting EV motor to USA and Italy. We are currently participating in various EV projects in Korea. If you are interested in doing business with HIGEN MOTOR, please continue to review our homepage and contact the undersigned to discuss further details. For further information, please refer to www.higenmotor.com/eng. CEO JaeHak, Kim 2/54 1.2 CEO Profile Education : Professional Activities : Seoul National University, Korea, BS Massachusetts Institute of Technology, Cambridge, Massachusetts, MS University of California, Berkeley, California, Ph. D. Harvard University, Graduate School of Business Administration, Boston, Massachusetts, MBA Presidential Advisory Council for Science & Technology, Member of Energy Subcommittee Korea Engineers’ Club, Vice Chairman The Korean Society of Mechanical Engineers (KSME), Vice Chairman, Chairman of Pressure Vessel Committee National Academy of Engineering of Korea, Full Member Seoul National University Alumni Association, Director Korea Motion Control Association, Chairman Mechanical Engineering Alumni Association, Vice Chairman The Korean Society for New and Renewable Energy, Vice Chairman The Korea Association of Machinery Industry (KOAMI), Vice Chairman The Korea Electrical Manufacturers Association (KOEMA), Vice Chairman Korea Electrical Engineering & Science Research Institute, Director Korea Plant Industries Association, Vice Chairman The Korea Atomic Industrial Forum, Director Korea-U.S. Economic Council, Director Korea Electrical Association, Director Korea Management Association, Director Korea Energy Association, Director Work experience : HIGEN MOTORS CORPORATION (2008.1.1~ ) Chairman and Founder HYOSUNG CORPORATION (2001. 12 ~ 2007. 6) President / CEO, Representative Director Power & Industrial Systems Group Doosan Heavy Industries & Construction Co., Ltd. (1999~2001) (Formerly Korea Heavy Industries and Construction Co., Ltd.) Executive Vice President & Chief Operating Officer, Rep. Director POSCO Engineering and Construction (1995~1999) Executive Vice President & Head of Overseas Business Division, Member of Board of Directors The World Bank/IBRD (1992~1995) Task Manager in China and Mongolia Dept, managed industrial And Energy projects in China. Korea Heavy Industries and Construction Co., Ltd. (1977~1992) (Currently Doosan Heavy Industries and Construction Co., Ltd.) Executive Managing Director & Head of Corporate Planning and Control Division. Member of Board of Directors 3/54 1.3 HIGEN is … 4/54 1.4 History Years of Experience 50 years of the legacy of HIGEN in motor business under the brand names of LG and HIGEN showcases remarkable milestones as chronicled below as one of the big 3 motor manufacturers in Korea covering variety of industrial applications such as pumps, reducers, plastic extruders, hydraulic, cooling towers, elevators and air handling machinery markets. In the motion control industry, HIGEN is the first in Korea to obtain EtherCAT conformance certificate and pioneers the EtherCAT based servo control industry. - 1963 -1994 - 2003 - 2008 - 2009 - 2010 - 2011 - 2012 - 2012 Started motor production. Servo Motor and Drive developed for commercial production. Obtained High Efficiency certificates , launched HIGEN brand. Separated as a motor specialty independent company “HIGEN MOTOR”. Obtained ATEX certificates. Awarded the Presidential award in the National Quality Management Contest Obtained ISO/TS 16949 Passed EtherCAT Conformance Test for servo network. Delivered 2500kW induction motor to HITACHI, Japan. 5/54 1.5 Overview South Korea Seoul Office : 2F, Korea Association of Machinery Industry Bldg., 13-6, Yeouido-Dong, Yeongdeungpo-Gu, Seoul, Korea Tel : +82-70-7708-8037 Fax : +82-2-369-8229 N W+E S Daegu Office Busan Office Landscape Site And Employees KwangJoo Office ChangWon Factory Head Office / Factory : 57 Gongdan-ro 473beon-gil, Seongsan-gu, Changwon-city, Gyeongsangnamdo, Korea Tel : +82-70-7708-8030 • 32,058 m² • 270 People Production Capacity 800,000 Sets/Year ANNUAL Turnover • 2010 : 68.7Mil. USD • 2011 : 74.9Mil. USD • 2012 : 66.4Mil. USD 6/54 Products • High Voltage Motors • Low Voltage Motors • Explosion Proof Motors • Vector Inverter Motors • Elevator Motors • Single Phase Motors • Electric Vehicle Motors • Spindle Motors • Servo Motors & Drives 1.6 Product Portfolio Products Application Output Range Production Capacity High Voltage Motors • 690~13,800V • TE, DP Power Plants, Water Supply Pulp/Paper, Petro-Chemical Mining, Other Industries 75~3,000kW 1,500 sets/year Low Voltage Motors • 200~690V • 1Φ, 3Φ • TE, DP General Industrial Use Pump, Fan/Blower, Compressor etc. 0.1~2,000kW 500,000 Sets/year Used in a location where explosive gas is present. 0.4~1,000kW Motors • 200~6,900V • Exd, Exe, Exn • T4/T5/T6 Elec.Vehicle Motors • InductionType • PMSM Type High speed Car Low speed Car Subway,Train 3~20kW 18~150kW 200~300kW Proto Producing Servo Motors & Drives • H.Inertia PMSM • L.Inertia PMSM Factory Auto. System CNC System Robot 0.05~75kW 40,000 sets/year Elevator Motors • Geared Type • Gearless Type Elevator Traction machine 5.5~75kW 30,000 Sets/year Explosion Proof 7/54 ATEX Certificate (LV 0.2~260kW) 5,000 Sets/year Outline picture 1.7 Corporate Organization Employees by occupation and career Career (Years) Design R&D ~5 5 ~ 10 10 ~15 15 ~ Total 7 1 8 7 23 4 2 3 6 15 MFG MFG Test tech 0 0 2 7 9 0 0 7 28 35 0 0 3 6 9 QC Etc. Total 0 0 3 4 7 32 23 65 52 172 43 26 91 110 270 High Voltage Business Unit Small Size Design Eng. Team H.G. Kim H.J. Kim Large Size Design Eng. Team T.I. Park CEO Dr. Jae Hak Kim CPO CMO R&D Center Jin Hong Kim Sun Yong Kim Dr. C. Choi USA Branch Office Export Sales Team Domestic Sales Team Domestic A/S Team Steve Hwang W.H. Moon Y.S. Joo M.S. Kim Production Management Team Material Logistics Team Purchasing Team Quality Assurance Team Production Team H.J. Paeng M.J. Park G.T. Noh H.T. Kim H.K. Kim 8/54 1.8 HIGEN’s Customers INDUSTRY CUSTOMERS Power Plant Iron & Steel Pump Compressor Fan 9/54 1.9 Key Clients POSCO KOREA ELECTRIC POWER Co. OTIS Elevator ( Seoul Yeouido SIFC ) Korea Zinc YoungPoong Precision 10/54 1.10 Certificates ISO QUALITY CERTIFICATIONS ISO 9001: Quality assurance in Design, Development, Production, Installation, Servicing - ATEX & IECEx - Construction and verification test of explosion proof enclosure of electrical apparatus International Automotive Task Force UNDERWRITERS LABORATORIES INC. (UL) - ISO/ TS 16949 : 2009 - Electric Vehicle Motors - Hydraulic Elevator Motors ( TEFC & ODP ) - UL Insulation System (F Class) CANADIAN STANDARDS ASSOCIATION (CSA) - Hydraulic Elevator Motors ( TEFC ) - Servo Drives ( COC ) - Induction Motors ( DOC ) 11/54 1.11 Quality Assurance HIGEN’s Quality Assurance System meets the demands of ISO 9001. As a global company, we are committed to comprehensive quality management system with focus on customer satisfaction. Customer Quality Policy QA Manual Procedure for Quality Control Instructions/Manuals & Standards for Working 12/54 1.11 Quality Assurance [Organization of Quality Assurance] Quality Assurance Team General Manager Quality Assurance, Acquisition of Certificates Standards Management, Post Management Manager Y. H. Lee Quality Assurance system Parts/Products Quality Control Inspection & Test Service Management Mngr S.R.Park Staff S.H.Choi Mngr I.S.Lee Mngr B.J.Choi Staff T.G.Yun Sfatt H.J.Park HV,EV,Traction - Construction of Quality Assurance System .Establishment & Amendment of Department Standards .Quality Review (Process, System) - Standards Management, Post Management - Acquisition of Certification (ATEX, KGS, UL, CE etc..) - Management for Measuring Instruments - Proposal Management H.T. Kim LV Motors Servo Motors - Inspection and Test - Witness Inspection - Facility Investment - Technical Consultation for Customers - Job Performance, Team Records LV/HV Motors Servo products - Site Service - Technical Assistant - Repair and Cause Analysis for Claimed Products - Service Parts control Inspection J.G. Park HV, LV Induction Motors Servo Products Receiving / Outgoing Inspection Receiving / Outgoing Inspection 13/54 1.12 Overseas Networks 14/54 2. High Voltage Motors 2.1 HIGEN HV Motors ……………………………………. 2.2 Strength Power ……………………………………… 2.3 Totally Enclosed Motors …………………………… 2.4 Open Drip Proof Motors ………………………….... 2.5 Polytight-T Insulation System ……………………. 2.6 Design Process ………………………………………. 2.7 Features ….……………………………………………. 2.8 New Products …….…………..………………………. 2.9 Manufacturing Facilities …….……………………… 2.10 Inspection & Test Facilities …...………………….. 2.11 Supply Records ….………………….………………. 15/54 16 17 18 19 20 23 25 29 30 34 35 2.1 HIGEN HV Motors HIGEN has supplied high voltage induction motors for power stations, pumping stations and many other kinds of industrial applications for decades. Through these years, reliability and quality of HV motors have greatly improved with experience accumulated on each stage of production from design, manufacturing, testing, and installation. Especially, HIGEN has successfully developed a high voltage insulation system of 15,000volts class for power plants. HIEGN’s HV motor employs class F excellent insulation systems, and its structure is designed and manufactured for low vibration and noise. Its deep slot or double cage rotor structure and special varnish finishing allows HIGEN HV motor to run perfectly under a wide variety of loading conditions for a wide spectrum of moment of inertia. HIGEN provides the motors either in cast iron frames or steel fabricated frames complying with IEC standards. HIGEN’s experience of half century has designed, produced and built to provide a highly versatile, easy-to-maintain range of drives suitable for the most power applications. - Output range : 75~2500kW, 2~28P - Time Rating : Continuous - Rated Voltage : 3000V/50Hz, 3300V/60Hz, 6000V/50Hz, 6600V/60Hz, 10kV/50Hz, 13kV/60Hz - Insulation, Temperature rise : Class F insulation, 80K rise - Ambient Temperature : -20 ~ +40℃ - Bearings : Regreasable ball or roller bearings, Sleeve bearings - Types and Starting Torques : .Type HEA ; Squirrel-cage, starting torque 50% or above of full-load torque. .Type FEK, HEK ; Squirrel-cage, starting torque 100% or above of full-load torque. .Type FEF ; Squirrel-cage, starting torque 150% or above of full-load torque. - Connection to Load : Direct drive or V-belt drive (for Cast Iron Frame Motor only) - Direction of Rotation : Counterclockwise viewed from drive end. - Finish in munsell Notation : 5PB 8 / 2.5(Blue) - Applicable Standards : IEC60034, NEMA MG1 16/54 750kw 4P 6kV 50Hz HV Motor 2.2 Strength Power -Superior Performance ; Standard construction utilizes copper bars, end rings and high grade, low loss silicon steel laminations to minimize eddy current losses and provide large thermal reserves, resulting in improvement of efficiency. High efficiency and low starting current achieve an outstanding reduction of operating costs. -New Polytight-T Insulation System ; High reliability and an effective insulation system go hand-in-hand. Fabrication Frame motors employ a newly developed insulation system called Polytight. Since Polytight is highly resistant to moisture and chemicals such as acid, alkali and salt water, Fabrication Frame motors are especially suited for applications under adverse operating conditions. -Ease of Maintenance ; Easily removed cooling unit, mounted on top of the motor frame, and wide utilization of antifriction bearings facilitate inspection and maintenance. Oil lubricated motors are also manufactured as standard. -Light Weight, Compact, Rugged ; Based upon extensive analyses of structural characteristics, ventilation systems and thermal properties, fabrication frame motors have been made more compact, lighter in weight, yet more rugged than their conventional counterparts. -Quiet Operation ; Optimized slot designs plus aerodynamic fans assure low noise. In addition, employment of tight fit and precisely balanced rotating parts minimize vibration and the improvement of the silencer diminishes running noise. 17/54 Sectional view of typical MV Motor 2.3 Totally Enclosed Motors TEFC IEC IP44, IC411/Rib Cooled, IC611/With Air-to-Air Heat Exchanger… For dusty, damp, or corrosive gas environments Type FE or NFE ; In a cast iron frame motor, fresh air comes from the opposite drive end bracket, is circulated inside the motor, and exhausted through the drive end. Type HE ; A heat exchanger is mounted on top of the motor top to replace the hot inside air with the cool outside air. Features a closed ventilation system utilizing a heat exchanger, which can be cleaned by simply removing a bolted cover. [Type FE ; Cast Iron Frame] [Type NFE ® ; Cast Iron Frame] 18/54 [General Ass’y of Type HE] [Type HE ; Steel Fabricated Frame] 2.4 Open Drip Proof Motors ODP (NEMA WP-I/II), IP23/IPW24, IC01/IC05 ODP motors are best suited for indoor applications and applications not exposed to extreme ambient conditions. The cooling-air paths are arranged to effectively cool the electric parts of a motor by weaving through the coils and core by agitation fan and air baffles. Suitable sound baffles and sound absorbing lining inside the cooling unit minimize noise levels. NEMA WPII on outdoor use motors also can be supplied by customer’s request. [General Ass’y of Type BDA] [BDA ; Steel Fabricated Frame] [BDA ; Outdoor Use, Sleeve BRG] 19/54 [BDF ; Cast iron Frame] 2.5 Polytight-T Insulation System “Polytight T” Insulation system is based on full vacuum pressure impregnation(shortly VPI) with epoxy resin varnish and mica. The system guarantees excellent heat-resistance and power-durability. FEATURES [Stator Assembly after VPI] HIGEN Motors TYPICAL Megger (MΩ) 1000 HIGEN Motors Cycle Life (h) BreakDownVoltage (KV) - Thermal class F, but can be extended for use in 180℃(class H) - Insulation Life is about 2 times of the polyesterimide resin system. - High adhesion of epoxy impregnating with assembly of core and coil recovers the insulation resistance in submersion within 1 day. -The motor with Polytight-T Insulation System may be used in humidity of over 90%. Leave in air 100 TYPICAL 10 Submersion 15 Life (h) [Cycle Life for BDV ] Temp (℃) [Cycle Life for heat] 20/54 24 Time (h) [Excellent for external environment] Vibration, Humidity and Chemical 2.5 Polytight-T Insulation System [Process of Coil making] [Coil winding] [Consolidation] [Spreading] [Coils after insulation] [Straight Part Insulation/Auto] [Coil End Insulation/Manual] 21/54 2.5 Polytight-T Insulation System [Process of Coil Assembly and Varnich Treatment(VPI)] [Preparing of Core] [Inserting/Connection] Vacuum 0.08 torr 3hr [Insulation Diagnosis] Pressure 6.5bar 5hr Curing 175℃ 10hr [VPI Processing] 22/54 [After Coil Assembly] [VPI Facility(Φ3000)] 2.6 Design Process HIGEN improves and optimizes products through MAXWELL/ANSYS to calculate magnetic fields, structural stresses and inertia. Through these analytical tools, an optimal solution to customers’ requirements are met. Magnetic field analysis Heat flow analysis(CFD) Structural analysis(ANSYS) Preliminary Decisions Preprocessing Solution Postprocessing 23/54 2.6 Design Process [Typical Design Process] Review SPEC Elec. Design Applicable STD. Checking Quality Req’d Checking Operat’g condition Mech. Design IEC,NEMA,IEEE… Customer’s Req’d Applicable Software Electrical Calculation Program (HIGEN) Maxwell, Flux 2D Check Shaft Check BRG Check Cooling Drawing Design Review 24/54 Applicable Software AUTOCAD, ANSYS HIGEN’s STD 2.7 Features Structures are designed for sufficient safety margin to ensure reliable operation of HIGEN HV motors. HIGEN standard products offer cast iron frames for FE/NFE type(TEFC) and steel fabricated steel frames for HE type(CACA) respectively, and they have high structural strengths, corrosive resistance and durability. Especially cast iron frames from 250Fr to 560Fr are kept in stock to respond to customers’ short delivery schedules. HIGEN designs its shaft diameter comparatively larger than its competitors to ensure that the rotor’s critical speed is sufficiently outside of the operating speed range. Designs with the use of analysis programs and prototype tests leads HV motors to achieve low vibration and high operational stability. The rotor end brazing is done by technicians with over 20 years experience, which further assures the rotor safety & stability during its operation. [Structure analysis] [Cast iron Frames in Stock ] 25/54 [Brazing Job on Rotor] 2.7 Features Cooling fans are optimally designed through repeated tests to reach a low level of temperature and noise. For example, heat dissipation of TEFC motor(fin cooled) is maximized through higher fin heights of cast frames and precision machining of outside of stator cores and the resulting maximum contact between stator cores and their frames. A internal fan is assembled to a rotor shaft to force hot air inside the motor to circulate and the inside temperature to cool down effectively. HIGEN’s thermal analysis(Computational Fluid Dynamics) of the motor and rich experience delivers efficient cooling system, reduction in machine losses and low level noise. Cooling fans and fan covers are chosen to adequately meet rotational speeds and motor sizes that minimize noises. Further, noise absorbing materials may be used in accordance with customers’ specific requests. Magnetic noise level is reduced by using optimal slot combination and the other technics. [High cooling fins, Machined Stator] [Circulation Internal fan] 26/54 [Low Noise Fan cover and axial fan] 2.7 Features The ball and roller bearings can be greased while the motor is running. Waste grease is collected in a grease trap mounted on each end bracket. The used grease is removed with a single stroke of the discharge handle, simplifying inspection and . maintenance. In frame sizes 450 or above, roller bearings at each end absorb radial load, and ball bearings at the drive end absorb thrust load. This design assures stability and a longer life. Sleeve bearings employ efficient sealing between shaft and bearing to prevent lubricants from leaking either into the motor housing or outside the housing. The sleeve bearings are split into two halves. Removing the upper half exposes the bearing interior. Basically opposite side bracket should be insulated for HV Motors. [Ball/Roller BRG] [Sleeve GRG] BRG SHAFT [Single BRG type] [Double BRG type] 27/54 [Waste grease trap] [Insulated, opp side BRG] 2.7 Features HIGEN customizes designs to satisfy customers’ convenience and easy maintenance. HIGEN Motor responds to various specific requirement of customers with design variations. Terminal boxes could be attached on top or sides of a motor. Protective instruments such as space heaters, temperature sensors or vibration measuring devices could be attached [Forced air cooling, Explosion proof models and Flange types. ] by customers’ requests. Various Kinds of Customized models [Terminal boxes on top and sides of a motor ] [For Replacement, Sun cover for outdoor use] [Temp. Sensors] 28/54 2.8 New Products Motor integrated with a deep sea water pump was successfully developed by HIGEN Motor. FPSO is a floating production platform for deep sea oil drilling, and requires a lot of sea water as coolant of production facility and also for desalination facility for workers living on the platform. A sea water pump with capacity of 1,000㎥ was replaced by a new pump of 3,000 m3 capacity by a Korean shipbuilder and HIGEN Motor developed and supplied the first set of motors of 1250kW 4P 3300V to that Korean pump developer. This motor uses oil as coolant for motor inside and sea water for motor outside with a perfect sealing in between. This structure ensures cooling motor inside and bearing lubricant as well in an environmentally friendly manner. FPSO [Floating Production Storage and Offloading] 29/54 2.9 Manufacturing Facilities Process Name of Facility Q'ty Authorized Capacity Maker Date Remarks Casting - Outsourcing - - Castec Korea : 750-1 Hakjang-dong, Sasang-gu, Busan / 051-310-1141 LT,HT Core Punching & Laminating - Outsourcing - - Hangnam : 539-1 An-dong, Kimhae-city, Gyeongnam / 055-324-1074 LT,HT - Frame Machining (MIFEL) 1 - 80~180Fr Frame Machining - Bracket Machining 1 - Turning M/C (FRAME Machining) 1 - Turning M/C (BRACKET Machining) 1 - RADIAL DRILL 1 - Winding & Inserting M/C (Automatic Line) 1 - Winding & Inserting M/C (P16-1S,GSW2RS) 1 - Winding M/C (#1) 1 - Winding M/C (#2) 1 - COIL HEATER PRESS M/C 1 - 80~180Fr Bracket Machining - Swing:1,600mm - Table Capacity:3,000kg - Table Outside diameter:1250mm - Table revolution: Max 312rpm - Swing:1,100mm - Table Capacity:3,000kg - Table Outside diameter:800mm - Table revolution: Max 500rpm - Applicable size: Max M30 - Table:1000L*500W - Head stroke:300MM - External Diameter:110~170mm - Internal Diameter:50~85mm - Slot No.:16~36 - External Diameter:195~260mm - Internal Diameter:120~185mm - Slot No.:36~72 - M type:max1500ML, F type:max1580ML - 3p, 220V, 10Kw - Vertical moving device - M/F type:max1720ML - 3p, 220V, 15Kw - Vertical moving device - Max Temp:200˚C - Pressure:Side 6TON, Down 9TON - Capa:L=~1200mm, W=~150mm Machining Mush Winding Form Winding 30/54 MITSUBISHI 1990.6 LT NISHIDA 1990.6 LT HOMMA 1989.8 LT,HT HOMMA 1989.8 LT,HT JeongKongSa 1978.10 LT,HT ODAWARA 1989.6 LT SANKO KIKI 1987.6 LT YASKAWA 1989.4 HT OTIS 2009.6 HT SSEDA 2012.7 HT 2.9 Manufacturing Facilities Process Form Winding Varnish Impregnation (Low Voltage) Curing Varnish Impregnation (VPI for High voltage) Curing Name of Facility Q'ty Authorized Capacity - COIL weight:MAX 6kg - COIL length:400~1400mm - COIL cross section:Max 30*15mm - COIL weight:MAX 25kg - COIL length:600~2000mm - COIL cross section:Max 60*25mm - COIL weight:MAX 6kg - COIL length:300~1300mm - COIL cross section:Max 30*15mm - COIL weight:MAX 25kg - COIL length:300~2200mm - COIL cross section:Max 60*25mm - Output Voltage:Max. 30kV Impulse - Pulse speed:10counts/sec - Rising Time:Approx. 0.2~0.5us - Capacitor:20nF, ± 10 % - Size:1800(H)*750(D)*600(W), 100Kg - Preheating ~ Dry - 100~200℃ Auto Temp Controlled - Spreading M/C(#1) Hydroric control 1 - Spreading M/C(#2) Full automatic servo control 1 - Auto TAPING M/C Hydroric control 1 - Auto TAPING M/C Full automatic servo control 1 - INDING SURGE TESTER 1 - Automatic Varnish Line 1 - Manual Impregnation Device 3 - Impregnation Device(3sets) - Drying Furnace 3 - Drying Furnace(5sets) - Vacuum Pressure Impregnation(VPI) Facility 1 - Drying Oven 1 - Size:Φ3000*H3000 - Vacuum:0.05mbar - Pressure:7bar - Temperature:30~60℃ - Electricity:3P,380V,45Kw - Size:W3000*H3000*L4000 (inner effective 2700*2500*3700) - Temp:Max.200˚C(normal 0~180˚C) - Heater type:Aerofin 3Kw (12EA/36Kw) 31/54 Maker Date Remarks YASKAWA 1997.12 HT SFA 2010.11 HT YASKAWA 1997.12 HT SSEDA 2013.3 HT KAST 2013.12 HT Donghae ENG 1989.8 LT BooSeong 1991.7 LT ShinShin 1987.4 LT GUOJI Vacuum 2013.10 HT PNP 2013.10 HT 2.9 Manufacturing Facilities Process Die-Casting Rotor assembly Rotor gap Machining Balancing Name of Facility Q'ty Authorized Capacity Maker Date Remarks T.H.T 1991.2 LT,HT - Die-Casting M/C 1 - Shot Force :300ton - Clamp Force :300ton - Shot Sleeve Diameter:254~406.4mm - Shot Standard Sleeve:406.4mm - Max Shot Weight :45.4kg - TIG Welder 1 - Electricity:220V 12KVA, 4~300A - Wire dia: 0.9~1.2mm ACE 2011.8 HT - CO2 Welder 1 - Electricity:220V 15.8KW, 0~350A - Wire dia: 0.9~1.2mm HS 2011.11 HT - PRESS for Rotor assembly 1 - Electricity:220V 10Kw - Pressure: Max 60ton - Height: 2100mm Seill 1989.4 HT - Rotor external diameter (PAN-20) 1 - Bed Swing:520mm - Center Distance:1500mm DAEWOO 1983.12 LT - Rotor external diameter (PROTEC-710) 1 - Bed Swing:710mm - Center Distance:3000mm Hankook Machine Tools 1997.8 LT,HT - Lathe 1 - Bed Swing:1000mm - Center Distance:4000mm SEIBU 2004.5 HT - Rotor Balancing M/C (HM-19.1) 1 - External Diameter:600↓ - Weight:450Kg↓ - Length Capacity:1900mm HOFFMAN 1989.1 LT - Rotor Balancing M/C (SCHENCK) 1 - External Diameter:30~600 - Weight:1500Kg↓ - Whole Length:2000 NAGAYAMA 1997.8 LT,HT - Rotor Balancing M/C (JCH-3000HB) 1 - External Diameter:~1200 - Weight:3000Kg↓ - Whole Length:3000 JinWon 2009.3 HT 32/54 2.9 Manufacturing Facilities Process Name of Facility Q'ty Authorized Capacity Maker Date Remarks - Hydraulic Press (Stator Forcer) 1 - Pressure:30ton, Stroke:800 - Hydraulic Motor:7.5Hp 4P HoWon Hydrolic 1989.4 LT - Hydraulic Press (Bearing Forcer) 1 - Pressure:10ton, Stroke:500 - Hydraulic Motor:7.5Hp 4P HoWon Hydrolic 1989.4 LT - Oven for FRAME assembly 1 - Electricity:3P,380V,60Kw - Size:2450*3200*2300 (inner effective 1370*1450*1960) - Temp:Max.200˚C(normal 0~150˚C) - Heater type:Aerofin (51Kw) HANSUNG 2004.6 HT - Oven for BEARING assembly 1 - Electricity:3P,220V,6Kw - Size:1500*1500*1500H NAMBU Heater 1997.2 HT - Paint Booth & Dry Oven 1 - Booth Type:WaterScreen - Wind Speed:1.0~1.6M/Sec - Dry Oven Temperature:50~150 - Drying Time:10~20분 - Heater Type:Far Infrared Lighting HanSung 1989.4 LT - Paint Booth 1 - Booth Type:Dry type - Size:4500*4500* Φ600 ISU 2008.9 HT Assembly Painting 33/54 2.10 Inspection & Test Facilities [For High Voltage Motors] NO Formal Name 1 Electric Dynamometer 2 Temperature rise resting device (equivalent loading and superposition method) 3 High Voltage Tester 4 Authorized Capacity Q'ty Maker Date Remarks - Power : 1000kW - Voltage/Frequency : 0~6600V, 0~70Hz 1 Leepoong Dynamomemter 1998.08 - - Power : 2500kW - Voltage : (LV) 380/440/460/660/690 (MV) 3300/6600 (HV) 10000/11000/13200/13800 1 Namil engineering 2003.07 - - Voltage : 30kV - Leakage Current : 1A 1 Taeyang engineering 1998.08 - Insulation Tester - Range : 1000 GΩ - Voltage : 5kV 1 MEGGER 2012.03 - 5 Milli-Ohm Meter - Range : 20kΩ 1 LUTRON 1998.02 - 6 Digital Power Meter - Voltage/Frequency : 600V, 2~200Hz - Current : 20A 2 YOKOGAWA 2002.01 - 7 Sound Level Meter - 24~130dB(A) 1 SVANTEK 2006.05 - 8 Vibration Meter 1 RION 1997.01 - 9 Stroboscope - 40~35,000 rpm 1 SHIMPO 1998.05 - 10 Thermometer - (-)200~(+)400℃ 1 YOKOGAWA 2004.03 - 11 Vernier Calipers - 0~300mm/0.01 - 0~1,000mm/0.01 - 0~600mm/0.01 - 0~2,000mm/0.01 35 Mitutoyo 1997.11 - 12 Micrometer - 25~50mm/0.001 - 75~100mm/0.001 - 50~75mm/0.001 - 100~125mm/0.001 30 Mitutoyo 1997.11 - 13 Height Gauge - 0~600mm/0.01 - 0~1000mm/0.01 3 Mitutoyo 1998.04 - 14 Dial Gauge - 0.01mm - 0.002mm 10 Mitutoyo 1995.05 - 15 Film Thickness Gauge 2 Mitutoyo 1998.03 - - Frequency : 3~3kHz - Disp / Vel / Acc - Range : 1000μm 34/54 2.11 Supply Records HIGEN has supplied various kinds of HV Motors for Korean/overseas power stations, iron works, water supply stations and other industrial sites proving excellent performance and reliability. 35/54 2.11 Supply Records TEFC Outdoor Use_350kW, 4P ,6.6kV, Fr.315 TEFC Scalar Inverter Use 220kW, 8P, 440V, Fr.315 TEFC Sleeve BRG_135HP, 10P, 6.6kV, Fr..315 TEFC Vector Inverter Use 600kW, 4P, 440V, Fr.400 36/54 Flame Proof (Ex-d)_375kW, 4P, 380V, Fr.355 For Harbour Crane (Vector control) 1100kW, 6P, 690V, Fr.500 2.11 Supply Records Date of Supply 08-Jan 08-Feb 08-Feb 08-Feb 08-Mar 08-Mar 08-Mar 08-Apr 08-Apr 08-Apr 08-Apr 08-Apr 08-Apr 08-Apr 08-May 08-May 08-Jun 08-Jun 08-Jun 08-Jun 08-Jun 08-Jun 08-Jun 08-Jun 08-Jun 08-Aug 08-Aug 08-Aug 08-Aug Type & Capacity Type kW P V TEFC 945 2 6600 ODP 410 2 6600 ODP 215 4 6600 ODP 175 6 3300 TEFC 160 4 3300 TEFC 520 2 6600 TEFC 217 4 3300 TEFC 160 6 6600 TEFC 110 4 6600 TEFC 185 6 3300 TEFC 450 4 3300 TEFC 75 6 6600 TEFC 220 6 6600 TEFC 160 6 6600 TEFC 185 4 6600 TEFC 90 6 3300 TEFC 150 4 3300 TEFC 175 4 3300 TEFC 75 6 3300 TEFC 110 6 3300 TEFC 132 4 3300 TEFC 132 4 3300 TEFC 150 6 3300 TEFC 180 6 3300 TEFC 185 6 3300 TEFC 90 8 3300 ODP 185 4 3300 ODP 220 4 3300 TEFC 95 4 3300 Customer Q'ty Date of Supply HITACHI HITACHI Hanshin Machinery POONGSAN Corp. HYUNDAI Motor ( China ) Micom Korea / Champre Co. POSCO POSCO POSCO POSCO WILO POSCO POSCO POSCO WILO HYUNDAI Motor ( China ) Korea Rural Community Corp. POSCO HYUNDAI Motor ( China ) HYUNDAI Motor ( China ) HYUNDAI Motor ( China ) HYUNDAI Motor ( China ) POSCO POSCO POSCO KOREA ZINC Co., Ltd SeoRyung Engineering SeoRyung Engineering Sheraton Grande Walkerhill 1 2 1 2 1 2 3 1 1 1 10 1 4 2 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 08-Aug 08-Aug 08-Sep 08-Sep 08-Sep 08-Sep 08-Oct 08-Oct 08-Oct 08-Oct 08-Nov 08-Nov 08-Nov 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 08-Dec 09-Jan 09-Jan 37/54 Type & Capacity Type kW P V ODP 150 4 3300 TEFC 200 4 6600 TEFC 95 4 3300 TEFC 185 4 6000 TEFC 380 4 3300 TEFC 220 4 6000 TEFC 200 6 6600 ODP 270 2 6600 ODP 220 4 6600 ODP 280 2 3300 TEFC 260 6 3300 TEFC 500 6 6600 TEFC 700 ` 3300 TEFC 200 4 6600 TEFC 250 6 6600 TEFC 280 6 6600 TEFC 360 6 6600 TEFC 450 6 6600 ODP 650 4 6600 ODP 650 4 6600 ODP 400 2 3300 ODP 150 2 3300 TEFC 260 6 3300 TEFC 260 4 3300 ODP 300 6 3300 TEFC 110 6 3300 ODP 375 4 6600 ODP 390 4 3300 ODP 250 4 3300 Customer Q'ty WILO Shin Shin Machinery WILO WILO KOREA ZINC Co., Ltd WILO POSCO Hanshin Machinery Micom Korea / Champre Co. Micom Korea / Champre Co. Pohang Yukang Filtration Works Dongbu Steel Pyeongsan Metal (PSM) 1 2 3 4 1 4 1 1 1 2 1 8 4 2 1 3 1 1 2 2 2 3 4 10 1 1 2 3 2 Korea Midland Power / Bukjeju TPP POSCO POSCO POSCO POSCO WILO WILO Samjeong Turbine Samjeong Turbine Pyeongsan Metal (PSM) BANWOL Co., Ltd. Gumi Water Works POSCO WILO Andong Water Works Andong Water Works 2.11 Supply Records Date of Supply 09-Jan 09-Jan 09-Jan 09-Jan 09-Jan 09-Jan 09-Jan 09-Jan 09-Feb 09-Feb 09-Feb 09-Feb 09-Feb 09-Feb 09-Feb 09-Mar 09-Mar 09-Mar 09-Mar 09-Mar 09-Mar 09-Mar 09-Apr 09-Apr 09-Apr 09-Apr 09-Apr 09-Apr 09-Apr Type & Capacity Type kW P V TEFC 200 6 3300 TEFC 315 6 3300 TEFC 400 6 3300 ODP 260 6 3300 TEFC 110 6 3300 ODP 1050 6 6600 ODP 1050 6 6600 TEFC 160 6 3300 TEFC 1100 6 6600 TEFC 1300 6 6600 TEFC 700 6 3300 TEFC 650 6 3300 TEFC 185 4 6600 ODP 200 4 3300 ODP 370 6 3300 ODP 130 2 3300 ODP 150 4 3300 ODP 150 4 3300 TEFC 160 6 3300 TEFC 185 6 3300 TEFC 150 6 3300 ODP 671 2 3300 ODP 160 12 3300 ODP 75 4 3300 TEFC 160 2 6600 TEFC 185 4 3300 ODP 410 10 3300 TEFC 90 6 3300 ODP 370 6 3300 Customer Q'ty Date of Supply POSCO POSCO POSCO WeMi NongHyup ( Jeju ) POSCO WILO WILO POSCO Dongbu Steel Dongbu Steel Pyeongsan Metal (PSM) Pyeongsan Metal (PSM) LG Display ( China ) Seobong Pumping Station Seobong Pumping Station Micom Korea / Champre Co. Micom Korea / Champre Co. Okchun Water & Sewage Works POSCO POSCO POSCO POSCO Seongju Seongju Hanshin Machinery Korea Coal Corporation Gochang POSCO Seobong Pumping Station 1 1 4 1 2 4 4 6 2 6 1 1 2 2 2 1 1 1 4 1 1 1 6 2 2 1 3 1 2 09-Apr 09-May 09-May 09-May 09-May 09-May 09-May 09-May 09-May 09-May 09-Jun 09-Jun 09-Jun 09-Jun 09-Jun 09-Jun 09-Jun 09-Jun 09-Jul 09-Jul 09-Jul 09-Jul 09-Jul 09-Jul 09-Aug 09-Aug 09-Aug 09-Aug 09-Sep 38/54 Type & Capacity Type kW P V ODP 130 4 3300 TEFC 160 4 3300 TEFC 360 6 6600 TEFC 200 6 6600 TEFC 260 6 6600 ODP 300 6 3300 ODP 260 6 3300 ODP 150 4 3300 TEFC 380 4 3300 TEFC 200 6 3300 TEFC 280 4 4160 ODP 370 6 3300 TEFC 400 6 3300 TEFC 315 6 3300 TEFC 160 6 3300 TEFC 315 6 3300 TEFC 300 6 6600 TEFC 450 6 3300 ODP 160 2 3300 ODP 132 4 3300 ODP 150 4 3300 ODP 160 2 3300 ODP 220 4 3300 ODP 75 8 3300 ODP 335 4 3300 ODP 335 4 3300 ODP 220 4 3300 ODP 75 8 3300 TEFC 300 4 6600 Customer Q'ty WILO Sechon Booster Pump Station POSCO POSCO POSCO Korea Water Resources Corp. Hyosung EBARA Hyosung EBARA KOREA ZINC Co., Ltd Pohang Yukang Filtration Works LHE Seobong Pumping Station POSCO POSCO POSCO POSCO POSCO POSCO Samjeong Turbine HwaSeong Pump HwaSeong Pump Samjeong Turbine 2 2 1 1 1 1 1 1 1 2 1 1 6 1 4 1 1 1 2 1 1 2 1 1 1 1 1 1 1 Korea Rural Corporation (DasSeong) Korea Rural Corporation (DasSeong) Korea Rural Corporation (BooYeo) Korea Rural Corporation (BooYeo) Korea Rural Corporation (DasSeong) Korea Rural Corporation (DasSeong) STOCK 2.11 Supply Records Type & Capacity Type kW P V TEFC 315 6 3300 TEFC 400 6 3300 TEFC 400 6 3300 ODP 185 6 3300 09-Oct ODP 185 6 3300 09-Oct 09-Nov 09-Nov 09-Dec 09-Dec 09-Dec 10-Jan 10-Jan 10-Jan 10-Feb 10-Feb 10-Feb 10-Feb 10-Feb 10-Mar 10-Mar 10-Mar 10-Mar 10-Mar 10-Mar 10-Apr 10-Apr 10-Apr 10-May TEFC TEPC TEFC TEFC TEFC TEFC TEFC TEFC TEFC TEFC TEFC TEFC TEFC TEFC ODP ODP TEFC TEFC TEFC ODP TEFC TEFC TEFC WP1 450 240 300 261 261 110 190 250 160 190 255 260 280 160 320 320 315 315 110 320 450 440 630 224 6 6 4 2 2 6 2 4 6 2 2 4 4 6 16 16 6 6 4 2 4 2 2 4 Date of Supply 09-Sep 09-Sep 09-Sep 09-Oct Customer Q'ty POSCO POSCO POSCO Korea Rural Corporation (JangSeong) 5 10 4 1 Korea Rural Corporation (JangSeong) 1 3300 POSCO 3300 PoHang Sewage Treatment Plant 6600 DaeJoo Machinery 6600 Korea Midland Power / BoRyeong TPP 6600 Boryeong Power Plant 3300 Suewon 3300 KOREA ZINC Co., Ltd 3300 KOREA ZINC Co., Ltd 3300 POSCO 3300 KOREA ZINC Co., Ltd 3300 KOREA ZINC Co., Ltd 3300 KOREA ZINC Co., Ltd 4160 LHE 3300 POSCO 3300 HANSUNG Industry 3300 HANSUNG Industry 3300 POSCO 3300 POSCO 3300 Young Poong 3300 Hanshin Machinery 3300 FKMT 3300 Micom Korea 3300 Micom Korea 4160 Korea Hydro & Nuclear Power 1 1 3 1 1 1 1 3 2 1 1 2 1 5 1 1 3 5 1 1 2 1 1 1 39/54 Date of Supply 10-Jun 10-Jun 10-Jun 10-Jun 10-Jul 10-Aug 10-Aug 10-Aug 10-Sep 10-Sep 10-Oct 10-Oct 10-Oct 10-Oct 10-Nov 10-Nov 10-Nov 10-Nov 10-Nov 10-Nov 10-Dec 10-Dec 10-Dec 10-Dec 10-Dec 10-Dec 10-Dec 11-Jan 11-Jan Type & Capacity Customer Type kW P V TEFC 250 2 3300 KOREA ZINC Co., Ltd TEFC 300 4 3300 KOREA ZINC Co., Ltd TEFC 325 4 3300 KOREA ZINC Co., Ltd TEFC 175 6 3300 POSCO TEFC 600 4 3300 KOREA ZINC Co., Ltd ODP 135 6 3300 Korea Rural Corporation (AnSeong) ODP 320 2 6600 Hanshin Machinery ODP 180 4 6600 Hanshin Machinery ODP 75 4 3300 Hapcheon County Office ODP 75 4 3300 Hapcheon County Office TEFC 400 6 6600 POSCO TEFC 375 4 3300 UlSan Water Works TEFC 225 8 3300 Hanshin Engineering TEFC 110 8 3300 Hanshin Engineering ODP 160 2 3300 Hanshin Machinery TEFC 200 4 6600 WILO TEFC 200 4 6600 WILO TEFC 110 4 6600 WILO TEFC 110 4 6600 WILO TEFC 160 4 6600 WILO TEFC 110 4 6600 WILO TEFC 160 4 6600 WILO TEPC 160 4 6600 Devi Mahinery TEFC 600 4 3300 POSCO TEPC 160 4 6600 Devi Mahinery TEFC 580 4 6600 POSCO TEPC 110 4 6600 Devi Mahinery ODP 320 2 3300 Hanshin Machinery ODP 75 4 3300 Hanshin Machinery Q'ty 2 2 2 6 1 1 2 1 1 1 1 1 1 1 1 3 2 2 2 1 1 1 1 1 3 1 4 1 1 2.11 Supply Records Date of Supply 11-Feb 11-Feb 11-Feb 11-Feb 11-Feb 11-Mar 11-Mar 11-Mar 11-Mar 11-Mar 11-Mar 11-Mar 11-Mar 11-Mar 11-Apr 11-Apr 11-May 11-May 11-May 11-May 11-May 11-May 11-Jun 11-Jul 11-Jul 11-Jul 11-Aug 11-Aug 11-Sep Type & Capacity Customer Type kW P V TEFC 132 6 3300 POSCO ODP 360 6 3300 HANSUNG Industry TEFC 235 4 6600 POSCO TEFC 132 12 3300 Korea Rural Corporation (GooMi) TEFC 132 12 3300 Korea Rural Corporation (GooMi) TEFC 250 4 3300 KOREA ZINC Co., Ltd TEPC 160 4 3300 DAEYOUNG Power Pump TEPC 90 4 3300 DAEYOUNG Power Pump TEFC 200 6 6600 POSCO TEFC 400 6 3300 POSCO TEFC 260 6 3300 POSCO TEFC 315 6 3300 POSCO TEFC 450 6 3300 POSCO ODP 75 14 3300 Korea Rural Corporation (CheonSuMan) TEFC 315 6 3300 POSCO TEFC 260 6 3300 POSCO TEFC 260 6 3300 POSCO TEFC 75 6 3300 POSCO TEFC 400 6 3300 POSCO TEFC 315 6 3300 POSCO TEFC 75 4 3300 Flutek Kawasaki TEFC 150 6 3300 Flutek Kawasaki TEFC 380 6 3300 KOREA ZINC Co., Ltd ODP 160 4 3300 Hanshin Machinery TEFC 150 4 3300 Hanshin Engineering TEFC 150 6 3300 Hanshin Engineering TEFC 400 6 3300 POSCO TEFC 200 6 3300 POSCO ODP 150 4 3300 Namil Q'ty Date of Supply 3 4 1 1 1 4 1 2 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 11-Sep 11-Oct 11-Oct 11-Oct 11-Oct 11-Oct 11-Oct 11-Oct 11-Nov 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 11-Dec 12-Jan 12-Jan 12-Jan 12-Jan 40/54 Type & Capacity Type kW P V ODP 160 4 3300 TEFC 200 6 6600 TEFC 75 6 3300 TEFC 90 6 3300 TEFC 160 6 3300 TEFC 260 6 3300 TEFC 315 6 3300 TEFC 400 6 3300 ODP 360 6 3300 TEFC 90 6 3300 TEFC 90 6 3300 ODP 200 4 3300 ODP 210 12 3300 ODP 180 12 3300 ODP 120 10 3300 ODP 110 2 6600 ODP 170 2 6600 ODP 210 2 6600 ODP 220 2 6600 ODP 250 2 6600 ODP 290 2 6600 ODP 420 2 6600 ODP 470 2 6600 ODP 480 2 6600 ODP 580 2 6600 TEFC 600 4 440 ODP 160 2 3300 TEFC 175 6 3300 ODP 150 4 3300 Customer Q'ty Hanshin Machinery POSCO POSCO POSCO POSCO POSCO POSCO POSCO HANSUNG Industry POSCO POSCO GoSan Water Purification Plant Korea Rural Corporation (GooMi) Korea Rural Corporation (GooMi) Korea Rural Corporation (GooMi) Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea Micom Korea POSCO Hanshin Machinery POSCO Kwangshin Machine 1 1 1 1 1 1 2 1 8 5 2 1 1 1 1 1 1 2 3 1 2 3 1 1 1 8 2 1 1 2.11 Supply Records Date of Supply 12-Jan 12-Mar 12-May 12-Jun 12-Jul 12-Aug 12-Aug 12-Aug 12-Sep 12-Sep 12-Sep 12-Sep 12-Sep 12-Sep 12-Nov 12-Nov 12-Nov 12-Dec 12-Dec 12-Dec 12-Dec 12-Dec 12-Dec 12-Dec 13-Jan 13-Jan 13-Mar 13-Mar 13-Apr Type & Capacity Customer Type kW P V ODP 150 2 3300 Hanshin Machinery TEFC 710 4 6600 DEWA(Dubai Electricity & Water Auth), UAE TEFC 337 4 6600 Korea Southern Power / Hadong TPP ODP 400 2 3300 Namil TEFC 400 6 6600 Shinil Eng TEFC 370 8 380 Changwon Engineering TEFC 450 6 6600 Shinil Eng ODP 450 2 380 Kwangshin Machine ODP 525 12 6600 HANSUNG Industry TEFC 1295 6 6600 Dongbu Steel ODP 950 8 6600 HANSUNG Industry ODP 950 8 6600 HANSUNG Industry TEFC 1270 2 6600 ICL (Bromine Compounds), Israel ODP 2500 4 6000 HITACHI Setsubi TEFC 450 8 6900 Korea Midland Power / BoRyeong TPP ODP 390 14 3300 HANSUNG Industry ODP 390 14 3300 HANSUNG Industry ODP 410 2 380 Micom Korea ODP 500 2 380 Micom Korea ODP 410 2 380 Micom Korea ODP 500 2 380 Micom Korea TEFC 1120 6 690 POSCO ODP 630 2 3300 Micom Korea ODP 400 2 380 Micom Korea TEFC 600 4 440 POSCO ODP 400 2 380 Micom Korea TEFC 450 4 3300 WILO EnerGreen Technology TEFC 450 6 6600 POSCO TEFC 370 4 380 Kwangshin Machine Q'ty Date of Supply 1 1 1 1 1 2 2 1 1 1 2 2 1 1 1 1 1 1 1 1 1 1 1 1 8 1 3 1 1 13-May 13-Jun 13-Jun 13-Jul 13-Jul 13-Jul 13-Aug 13-Aug 13-Aug 13-Aug 13-Aug 13-Aug 13-Sep 13-Sep 13-Sep 13-Sep 13-Sep 13-Oct 13-Oct 13-Oct 13-Oct 13-Oct 13-Oct 13-Oct 13-Oct 13-Nov 13-Dec 13-Dec 13-Dec 41/54 Type & Capacity Type kW P V WP2 635 6 6600 WP2 700 2 6900 ODP 1195 8 3300 WP2 630 6 6600 TEFC 450 8 6600 WP2 500 8 6600 TEFC 220 4 6000 TE 335 4 380 DP 500 8 6600 TE 500 6 6600 ODP 1200 8 3300 TE 320 4 6600 TEFC 185 6 3300 TE 200 4 6600 TE 200 4 6600 ODP 420 2 3300 ODP 440 2 3300 TEFC 460 4 6000 TE 300 6 380 TE 335 4 380 DP 300 4 3300 DP 500 8 6600 DP 500 8 6600 DP 590 6 6600 DP 590 6 6600 DP 1715 6 6600 TEFC 600 2 6600 TEFC 450 4 3300 TEFC 300 6 3300 Customer Q'ty Korea Western Power Co., LTd. 1 1 2 1 1 1 1 1 1 1 2 2 2 2 2 1 1 1 1 2 1 1 1 2 1 1 1 1 1 Korea Midland Power / BoRyeong TPP Korea Water Resources Corp. Korea South East Power / Samchunpo TPP Korea South East Power / Samchunpo TPP Korea Southern Power / Busan N.Gas P/P Menzel Korea Energy JangSeong Korea Southern Power / Busan N.Gas P/P Dongbu Steel Dangjin K Water DongYang/Plant Division/POSCO Namil JangSeong DongYang/Plant Division/POSCO DongYang/Plant Division/POSCO Mycom Korea Mycom Korea Menzel Korea Energy JangSeong Korea Energy JangSeong Hanshin Machinery HANSUNG Industry Paju HANSUNG Industry Paju HANSUNG Industry Hapcheon HANSUNG Industry Hapcheon Busan Purification Plant Mycom Korea Korea Coal Corporation Korea Coal Corporation 2.11 Supply Records 14-1 14-1 Type & Capacity Type kW P V TEFC 450 4 3300 TEFC 185 2 3300 14-1 TEFC 373 4 3300 14-3 TEFC 132 4 3300 14-4 TEFC 720 2 6600 14-4 TEFC 335 6 6600 14-5 TEFC 420 4 6000 14-5 TEFC 750 4 11000 14-6 TEFC 515 8 6600 Date of Supply Customer Q'ty Korea Coal Corporation 1 2 YPP BanWol Korea South East Power Corp Samchunpo Thermal Power Plant Korea Agriculture & Fishery Corporation Korea Midland Power Corp. Boyung Thermal Power Plant Han Sung Heavy Industry SeoWon Poongryuk Machinery Co. Ltd MENZEL, Germany Korea East West Power.Corp Dangjin Thermal Power Plant 1 2 1 5 2 1 2 42/54 Date of Supply Type & Capacity Type kW P V Customer Q'ty 3. Low Voltage Motors 3.1 HIGEN LV Motors ………………….…………………. 3.2 General Purpose Motors …………………………… 3.3 Motors for Pumps ………….………………………… 3.4 Explosion Proof Motors ……..……………………… 3.5 Electric Vehicle Motors ………………….……..…… 3.6 Special Purpose Motors …………………….………. 43/54 43 44 45 46 47 48 3.1 HIGEN LV Motors HIGEN based on high technology accumulated since 1963 in producing General Purpose LV Motors through modern equipment. Standard motors meet requirements of IEC, NEMA and are recognized by CSA, UL, CE, ATEX and ISO 9001. To satisfy customer’s needs, HIGEN is also producing various Special Purpose Motors. FEATURES - STATOR AND WINDINGS . Used high quality silicon steel with low core loss. . Secured high insulation by high class varnish treatment. - ROTOR . Made through aluminum die casting with end rings and cooling blades. . Reliable operation with low vibration ensured with CNC balancing machines. - COOLING FAN & FAN COVER . Low noise and wind loss minimized through optimum air circulation. . Optimum size selection for each frame sizes. . Steel fan cover is designed for adequate air circulation and strength - FRAME & END BRACKET . Precision machining to ensure center for accurate combination of bearing and durability of structure. - BEARINGS . High quality double shielded, pre lubricated ball bearings. . Open bearings for easy maintenance. - CONDUIT BOX . Rotates 90 degrees. . Gasket is installed to prevent damages to lead wires and for easy mounting on the frame. - NAME PLATE & FINISHING . Each component is finished with high quality corrosion resistant paint. 44/54 3.2 General Purpose Motors GENERAL SPEC. - MOUNTING TYPE Horizontal, Vertical - RATING Continuous - AMBIENT TEMPERATURE -10℃ ~ 40℃ - SITE ALTITUDE Below 1000m TEFC FOOT-MOUNTED (B3) - ROTATION CCW from the view of shaft extension - INSTALLATION Indoor/Outdoor - SERVICE FACTOR 1.0, 1.15 - DEGREE OF PROTECTION IP44/IP55, IP22(ODP) TEFC FOOTLESS-MOUNTED (B5) ODP FOOT-MOUNTED HIGH EFFICIENCY MOTORS HIGEN High Efficiency Motors are designed with CAD and FEA(Finite Element Analysis) to minimize losses and reduce energy costs. The motors have been tested by IEEE 112 Method B and the Efficiency values are greater than EPACT’s. PERFORMANCE AND CONSTRUCTION FEATURES 1. Stainless steel nameplate. 2. High grade, insulated electromagnetic steel laminations. 3. Class F non-hygroscopic insulation with low temperature rise. 4. Fully tested and documented per IEEE 122, Method B or CSA standard 390. 45/54 HIGH EFFICIENCY MOTORS 3.3 Motors for Pumps The heritage of our solid market leadership in motor/pump industry in Korea dates back to 1969 when LG started pump production. WILO acquired pump business from LG in 2000, and HIGEN supplies 90% of WILO’s motor needs. Besides, Young Poong, KSB, Armstrong and other leading pump manufacturer selected HIGEN brand. 46/54 3.4 Explosion Proof Motors If internal explosion happens by the explosive gas that has penetrated into the inside of an airtight container, explosion structure should bear the explosion pressure and prevent the flame from spreading to the external explosive surroundings. Identification Code 0575 is the identification number of DNV responsible for the approval Exd 71~250M 0.2~90kW 4P 280M~315M 110~160kW 4P Exd 355Fr. 260kW 4P 47/54 [ATEX Certificate] 3.5 Electric Vehicle Motors In 2009, then President Myung Bak Lee, Republic of Korea, hosted a Presidential panel of the National Economic Committee to review the policy for the promotion of electrical vehicle (EV) as a strategic industry for Korea’s future economy. Dr. JAE-HAK KIM, CEO of HIGEN MOTOR (seated next to President M.B. Lee) and Hyun-Soon Lee, then Vice Chairman of HYUNDAI Motor Company were invited to brief on current industrial issues to high ranking government economic policy makers. Dr. JAE-HAK KIM CEO of HIGEN MOTOR PRESIDENT M.B.LEE At the close of the policy session held at HYUNDAI Motor R&D center, M.B. Lee took a test ride on a HYUNDAI’s prototype EV model powered by a water cooled AC motor designed and made by HIGEN Motor. Beside the HYUNDAI models, HIGEN Motor is currently exporting other types of EV motors abroad. HIGEN plans to launch additional heavy duty EV motor units of various applications such as bus, truck and yacht for the domestic and export markets. FEATURES - Securing structural stability at high speed - Spline Shaft Driving Method -Reinforcement of Insulation Performance for Inverter Voltage Surge 30kW EV Motor - Minimize the size and weight through High Power Density (kW/kg) . Application of High Quality Silicon Steel with Low Core-Loss and High Permissible Magnetic Flux. . Maximize Cooling Efficiency by High Current Density of Winding through the use of Aluminum Frame and Water Cooling System. 48/54 3.6 Special Purpose Motors HIGEN is producing many kind of Special Purpose Motors. VECTOR INVERTER MOTOR ALUMINUM FRAME MOTORS SINGLE PHASE IND. MOTORS SPINDLE MOTORS 49/54 HYDRAULIC UNIT MOTORS TE AIR OVER MOTORS (COOLING TOWER TYPE) ELEVATOR MOTORS HYDRAULIC ELEVATOR MOTORS 4. Servo Products 5.1 Servo System …………………….………..…………. 5.2 Network Based System ……..……………………… 5.3 MDA7000 …………………….………………………… 5.4 XGT Network Servo ……….....…………………….... 5.5 Application Area ………….……………….……..…… 50/54 50 51 52 53 54 5.1 Servo System HIGEN MOTOR is the first company in Korea whose servo drive passed EtherCAT Confermance Test assuring compatibilities with EtherCAT based network systems. HIGEN EDA 7000 Series opens a new horizon unfolding the era of EtherCAT based Motion Network application. FDA7000 Series Book-Type FEATURES 1Axis Motion Servo USAGE • Output : 0.05 ~ 37 kW(1/15HP ~ 50HP) • High Speed(32 bit) DSP Technology • Rapid Position & Speed Control • Low Noise by IGBT-IPM • Feed-forward Compensation Function • Low Inertia - Robot, Chip Mount, Factory - Automation • High Inertia - CNC System , Transfer Machine 51/54 Network-Type 5.2 Network Based System RS232, RS485 & Network communication. RS232 / USB RS232 / RS485 EtherCAT TOP 1 1 axis 2 axis 52/54 3 axis 8 axis 5.3 MDA7000 1 Axis Motion Controller Integrated Servo [ Servo ] [ 1Axis Motion Controller ] FEATURES [ Integrated Servo] SPEC. . Real time communication control by integrating servo and motion . Single position operation by DPRAM communication . Network connection by EtherNet . Simple Wiring by directing connection . Position, Speed and Torque Control . Linear, Limited/Unlimited Rotation Operation . Output : 50[W] ~ 3[kW] . Encoder : 17bit Serial ABS ENC. . Control Mode : Speed, Position, Torque, Sync, I-Mark . Program : Motion & PLC (Ladder) Program . Communication : EtherNet(100Mbps), RS422/485(1Ch), RS232C(1Ch) . Position Point : 7000 . Operating Mode : Single or Network (Max. 255) 53/54 5.4 XGT Network Servo 8 Axes Synchronous Network Servo Features - 100Mbps High Speed Network EtherCAT. - High-Speed, High-Accuracy Positioning by Real Time - Communication between Servo and PLC. - 8 Axes Synchronous Control by High-Speed Communication. - Exclusive Motion Software Provide for Multi-Axis Control - Simple Wiring by Network Communication. - Advanced Efficiency with Absolute Control. - High Performance & Low Price. [ Internal Type ] [ External Type ] 54/54 5.5 Application Area Articulated Robots LED Line Wafer Handling Robots 8 Axes Synchronous Control Servo System Pick and Place Robots 64 Axes Control Servo System SMT Take-Out Robots Machine Tool Auto Inspection Equipments 55/54 56/54