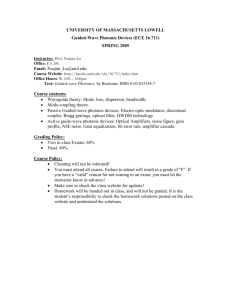

Photonic Crystals & fibres • Fundamentals of Photonic Crystals

advertisement

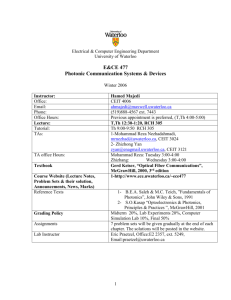

The LaRC Fiber Draw Tower Presented by Stan DeHaven Draw Tower Research • FOSS (Fiber Optic Sensing System) strain sensors. Use Bragg grating in fiber core. • Holey Fiber – Multi-core hollow fiber. Tens of Micron hole spacing. NUPERC activity. • PCF (Photonic Crystal Fiber) – Micron scale hole spacing. NUPERC activity. • Draw Tower Capabilities Fiber Optic Strain Sensor (FOSS) Bragg Gratings Bragg Grating Reflection Spectrum lb = center reflection wavelength of Bragg grating (lb) = center reflection wavenumber -1 reflection(%) 0.1 0 0.1 nm wavelength(nm) Bragg Grating as 2nd Reflector in an Interferometer L output reflector 1 7% Bragg grating < 0.1 % power Dw = -(2nL)-1 L = -(2nDw)-1 (lb) -1 decreasing wavenumber (increasing wavelength) Multiple Gratings, Multiple Interferometers L1 output reflector 1 7% L2 L3 Bragg gratings Dw1 = -(2nL1) -1 Dw2 = -(2nL2) -1 Dw3 = -(2nL3) power -1 -1 (cm) decreasing wavenumber (increasing wavelength) power FFT To Separate Gratings -1 (cm) power FFT cm L1 L2 L3 wavelength Typical Laser Sweep time FOSS Required Configuration reference signal Lref L1 data signal reflector (distance 0) L2 L3 Bragg gratings Electronics: reference signal c data signal A/D data signal sampled according to reference length fringes FFT To Separate Gratings power sampled set with -1 Dw=-(2nLref) spacing between samples number of samples = Nsam -1 (cm) FFT power “Spatial” set with -1 ((Nsam-1)Dw) between points cm L1 L2 L3 -1 FFT To Find Grating Spectra power “Spatial” set with -1 Dspat=((Nsam-1)Dw) point spacing L1 L2 L3 cm -1 FFT power “Spectral” set with -1 Dspec=((Nspec-1)Dspat) point spacing (lb) -1 -1 (cm) Bragg Grating Reflection Spectrum lb = center reflection wavelength of Bragg grating (lb) = center reflection wavenumber -1 reflection(%) 0.1 0 0.1 nm wavelength(nm) FOSS Draw Tower Operation Draw Tower Preform in Furnace Bragg Grating Optics Draw Tower View Excimer Laser (248 nm, 500mJ) Photonic Crystals & Fibers • Fundamentals of Photonic Crystals - What are photonic crystals? - Theory of Photonic Crystals • Photonic Crystal Fibers (PCF) • Fabrication of PCF • Advantages and Challenges Photonic Crystals & fibers What are photonic crystals? Features of a photonic crystal: • Made of low-loss periodic dielectric medium • Optical analog to the electrical semiconductors • Able to localize light in specified areas by preventing light from propagating in certain directions – optical bandgap. Theory of photonic crystals Theory of photonic crystals, con’t Theory of photonic crystals, con’t In 2D photonic crystal structures it is possible to confine light within a cavity. Photonic band gaps appear in the plane of periodicity and in 2D we can achieve linear localization. By introducing a defect, i.e. removing one column, we may obtain a peak in the density of states localized in the photonic band gap – similar to semiconductors. The defect mode cannot penetrate the crystal in the xyplane because of the band gap but extends in the zdirection Photonic crystal fibers By making a suitable geometry of the periodic dielectric medium, a phonic crystal can be used as an optical fiber. PCF Fabrication •PCF Preform Construction •PCF Drawing -similar to drawing capillary tubes Preform Construction Tubes are packed in a hexagonal shape with hollow, solid, birefringent, doped or tubular core elements. Multi-Core Preform Drawing PCF Preform of packed tubes is drawn in a draw tower furnace Preform drawing down in furnace Single tube drawing characteristics SEM Image of Multicore Fiber Multi-core Drop with drawn fiber Advantages: •PCF with high-index core is more flexible than conventional fiber: - Possible to make very large core area to send high power - Possible to make core very small compared to conventional fibers. Designer wavelengths possible. •Air-guiding PCF (hollow core of fiber): - Possible to send high power - No entrance or exit reflectance Challenges: •PCF is difficult to fabricate •PCF is limited to specific frequencies Draw Tower Capabilities • • • • • • Graphite Furnace Multiple heat zone furnace elements Fiber diameter feedback control IR and UV thermal fiber coating capability Excimer Laser Ability to write gratings while drawing fiber for increased fiber strength