role of the mineralogist/geologist in optimising the mining

advertisement

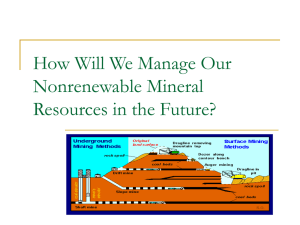

ROLE OF THE MINERALOGIST/GEOLOGIST IN OPTIMISING THE MINING VALUE CHAIN Dr. Johann Claassen February 2012 Content Future role of the mineralogist/geologist in the mining environment Holistic approach to optimising the mining value chain Impact of geology on the performance of the mining value chain Ore and mineral treatment processes Example Comments and questions Future role of the mineralogist/ geologist in the mining environment Current reality: > 95% of trained mineralogists/geologists work in the mining environment Geologists are more familiar with the ore and orebody characteristics than any other person at a mining operation Geologists tend to function in silos Remaining reserves are more complex and variable Shortage in skilled and experienced labour High volatility in labour market More intense regulation of natural resources Future role of the mineralogist/ geologist in the mining environment Future requirements: Sustainable exploitation of complex reserves(high variability) – find more effective and efficient ways to exploit mineral wealth System throughput driven focus Integration of ore and ore body knowledge with downstream processing requirements and the markets Integration of different functional groups at mining operations Integration of the strategical and operational environments at a tactical level More productive labour force Future role of the mineralogist/ geologist in the mining environment How to close the gap?: Geologists take the lead in: integration of knowledge and functional areas in the mining environment training in ore and ore body morphology and how it impacts the mining value chain training in mineral resource utilization principles (MRM) finding new ways to exploit complex mineral resources by working together with other disciplines (e.g.Geometallurgy) Geologists to: have a clear understanding of their role in optimising and STABILISING the mining value chain develop a better understanding of ore and mineral treatment processes develop a good understanding of MRM/material flow principles and how it affects the output of mining systems; TAKE A HOLISTIC APPROACH TOWARDS MANAGING THE MINING VALUE CHAIN Holistic approach towards optimising the mining value chain System focus: End-to-end process view It is the system that generates a final product and not the different departments/steps Align ore with the market requirements (pit to product principle) Manage throughput of the system: flow of material or information through the value chain (“Flow world” vs “mechanistic/accounting” approach) physical constraints and payable throughput attributes (impact of material characteristics on downstream processes and product value) Dependencies and inter-dependencies Stability of the system as a whole (very important due to variability in the ore and ore body morphology) Buffer levels Key value drivers (very often geology related, 80-20 principle) Future role of the mineralogist/ geologist in the mining environment Impact of geology on the performance of the mining value chain Ore morphology: Refers to the physical and chemical properties of an ore In the MRM context, the impact of ore morphology on the performance of downstream processes and the value of products produced are of interest The mineralogist/geologist is well positioned to advise a mining company on the physical and chemical characteristics of an orebody. Ore morphological characteristics and its impact: Micro texture – relationship between grain size and intergrowth irrespective of the mineral type: affects liberation potential of minerals and throughput Meso texture – relationship between mineral type and texture (massive, banded and disseminated ores): affects upgrading potential of ore and throughput Head grade: overlaps between different meso-textures may exist which could affect recovery if blending of ROM is not handled correctly. Grade-recovery conflict to be fully understood. Grindability: refer to the hardness of rock: affects recovery of valuable minerals when over/under grinded/liberated and throughput Deportment of valuable elements – refers to the way in which elements occur in the ore and it includes the genesis of the ore or mineral: affects mainly recovery of elements in hydro- and pyrometallurgical processes. Purity of the mineral crystal structure: displacement of elements in crystal structures/weathering effects, devolatilisation of coal: mainly affects mineral properties, which in turn affects the efficiency of beneficiation-, hydro- and pyrometallurgical processes. Precipitation of unwanted elements could adversely affect the performance of these processes. Impact of geology on the performance of the mining value chain Ore morphology (cont): Competing species – non-valuable minerals such as graphite, pyrite, carbonaceous materials interact with reagents: affects process efficiencies and the overall cost of operations Effect of phyllosilicates: consume reagents: affects process efficiencies and the overall cost of operations Non-recoverable valuable minerals or elements – unliberated grains and elements in oxides or carbonates cannot be recovered during beneficiation (zinc in dolomite, reaction products coating particles during hydro- and pyrometallurgical processes): affects recovery and throughput Mineralogical transformation during leaching: secondary product formation that requires an adjustment of conditions to ensure optimal extraction of valuable elements Devolatilisation effects – coal devolatilised because of dolerite activity: increased weathering and coal porosity that could influence recovery and reagent consumption (floatation) Weathering effects – oxidation and hydration of minerals that affects mineral surface composition: affects mainly recovery of minerals and elements Variation in RD – in-situ ore density variations: high levels of near-dense material will affect plant efficiency and throughput. MATERIAL COMPATIBILITY in dense medium separation processes could play a significant role in the performance of these processes and final product quality Hardness and porosity: porosity may reduce the SG of ores to such an extend that waste material become near density material; difficult to separate ore and waste Superfines – particles less than about 500micron: affects viscosity of dense media which in turn impacts recovery of minerals/ores Impact of variable mineralogy on downstream processes Complex mineralogy (what is the impact on downstream processes?) Paragenic sequence tennantite through chalcopyrite, bornite and chalcocite (Mascott Mine, Drake, NSW) Pseudo-eutectic intergrowth between bornite and carrollite (Mascott Mine, Drake, NSW) Bornite (Cu5FeS4) Chalcocite (Cu2S) Djurlite (Cu1.96S) Stannite (Cu2SnFeS4) Chalcopyrite (CuFeS2) Carrollite Co2CuS4) Tennantite (Cu12As4S13) Tennantite (Cu12As4S13) Paragenic sequence tennantite/bornite/ chalcopyrite and gold (Mascott Mine, Drake, NSW) Bornite (Cu5FeS4) Gold Covellite (CuS) Chalcopyrite (CuFeS2) Tennantite (Cu12As4S13) Bornite (Cu5FeS4) Impact of geology on the performance of the mining value chain Ore body morphology (geometry): Ore body geometry is a result of deposit style, host rock distribution and subsequent deformation. It impacts MINING CONDITIONS directly. Mining equipment selection and mining infrastructure development are to a large extend influenced by the ore body geometry. VARIABILITY in ore body morphology disrupts mining operations The use of average norms and standards to plan and measure mining performance destabilises the mining value chain where variability in ore body geometry is present Geologists need to: ensure that adequate data is gathered that not only describes the quality of an ore body but also the geometry (geophysics) ensure that mining standards developed (load tempo, drill tempo, etc) are conditionally driven (CDS) be wary of changes in ore body morphology from one area to the next (do not extrapolate data or logic to new areas) understand the impact that composite sampling may have on the quality of the data and geological model generated closely interact with mining operations during mining of complex ore bodies/seams (coal, iron ore, gold, Merensky reef) be wary of the impact that BLENDS may have on the performance of plant processes Impact of geology on the performance of the mining value chain Ore body morphology (cont.): Ore body morphological characteristics and its impact: Gradient/dip of an ore body/seams (incl. hanging and footwalls): mining equipment functions optimally in a horizontal plane and mining at gradients in excess of 8˚ cause DILUTION and lower THROUGHPUT (be wary of the use of average norms and standards for planning and equipment selection) Thickness of seams (ore and watse): variability in seam thickness leads to DILUTION, poor ORE EXTRACTION EFFICIENCIES and a reduction in mining TEMPOS Texture – joints, faults and fractures (areas of discontinuity): influences competence and position of material/seams that may lead to DILUTION, a reduction in loading TEMPOS and an increased SAFETY RISK Dolerite sills and dykes: lead to DILUTION and a reduction in loading TEMPOS Impact of variable ore body geometry on downstream processes Orebody morphological factors Dolerite dyke X Shale Contact Low Vol <13% Lean Coal 13%< Vol <18% Low Vol Contact Med Vol >18% Lean Coal Contact 8m Section 2 18 m Eskom O Shale Ore and mineral treatment processes Ore body Market Geology Mining Beneficiation & Processing Logistics Drilling Blasting Loading Hauling Physical processes Aqueous processes Hydrometallurgical processes High temp. processes Pyrometallurgical processes Ore and mineral treatment processes Physical processing: Size reduction: Crushing Grinding Milling MAG. SEP FILTER PRESS Plant Feed PRE-WASH SCREEN DRUM PROD DISC ROLL CRUSHER SPIRALS CC FC PPS PROD DISC PROD DISC PROD DISC PPS Disc Conv CC Prod. Conv Particle selection: Based on size (screening) Based on density (aqueous, dense medium, pneumatic) Based on magnetic properties (magnetic separation) Based on electrical properties (electrostatic precipitation) Based on surface chemistry properties (floatation) FC Prod. Conv SPIRAL PROD CONV CM DIL Bulk materials handling (conveyance and storage) Waste treatment Solid-liquid separation (thickening, filtration) CM DIL CM DIL THICKENER Ore and mineral treatment processes Aqueous solution processing Small Cathodes Separation processes: Leaching Precipitation Ion exchange Compound formation: Crystallisation Chemical precipitation Metal production: Cementation Gaseous reduction Chemical precipitation Electrowinning Manual Stripping Neutral Leach Zinc Dust Calcine Concs STORAGE `` ROASTER Pure solution Impure solution ELECTROLYSIS PURIFICATION LEACH 2 Units total 540t/d Cathodes Double Contact Residue 2 Stage Hot Acid SO ACID 2 Paragoethite Solution PLANT INDUCTION LEACH Sulphuric Acid MELTING 2 Linear Machines 25kg Pb/Ag Residue IRON REMOVAL 2 Membrane Paragoethite CASTING Jumbo caster (1 &2 tons) Pb/Ag ACID DRUM FILTER FILTER PRESS HG, SHG & ALLOYS STORAGE RAIL ACID FOR SALE RESIDUE STORAGE Cd, Cu & Co CAKE STOCKPILE Metal purification: Aqueous metal purification rarely done, focus is on upstream processes to purify solutions and compounds METAL FOR SALE Ore and mineral treatment processes High temperature processing Separation processes Vapour phase separation Chemical changes in the solid state Liquid/gas separation Compound formation Metal production From metal oxides From metal sulphides From metal halides Metal purification Compound formation Vacuum refining Zone refining Example: Zn metal production from Zn/Pb sulphide deposit CONCENTRATE PRODUCTION Zn METAL PRODUCTION Zn concentrate (54% Zn) Run-of-mine Crushing Milling As2O3 PbS flotation Pb concentrate Zn dust Zn dust ZnS flotation Tailings Zn concentrate (54% Zn) Zn metal Example: Zn metal production from Zn/Pb sulphide deposit Processing step Geological variables Potential impact 1. Crushing (3-stage) Hardness/grindability Throughput, cost (liner plates) 2. Milling Mineral associations, element replacement, particle size, hardness/grindability Under- and over milling, recovery losses, throughput, cost 3. PbS flotation Competing species (phyllosilicates) Reagent consumption, low recovery 4. ZnS flotation ZnCO3 in dolomite, competing species Low recovery, over-milling (fines losses, increased cost) 5. Roasting Element replacement - Fe in Zn structure leads to Zn ferrite (spinel) formation); sulphates in concentrate Sulphates increase electrolyte acidity – require neutralisation which leads to Zn losses and increased cost (neutralisation agents) 6. Leaching Fe impurities in Zn concentrate due to process efficiency and mineral associations Fe precipitates cover ZnO particles, Zn-ferrites are difficult to leach, recovery losses, production losses 7. Solution purification Co and Cd impurities in Zn concentrate (solid solution and intergrowth), SiO2 , Fe Reagent consumption (arsenic oxide), production loss if Co ends up in cell house, Silica gels blind filters – throughput and recovery losses, amorphous Fe phases leads to Zn recovery losses 8. Zn electrowinning Co and Cd affects adherence of Zn metal to cathode plates, Mg and Mn levels in concentrate affect solution density, current efficiency and cathode quality Production loss of up to 1 week, high running cost 9. Melting and casting Impurities in concentrates due to process efficiency, mineral associations and element replacement Reagent consumption, final product out of specification Comments and Questions