"Concrete" Canoe Designers and Further Info

advertisement

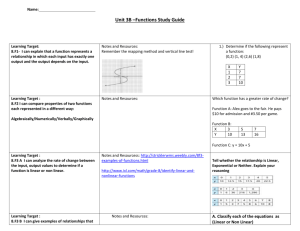

Who we are & some blurb “L g n W g n” by Seth Mathers and Martin Scott Seth This canoe is not made of concrete, but from a special set of ingredients which makes it a Geopolymer concrete. We didn’t realise it was a Concrete project. This type of special concrete replaces the traditional cement (Ordinary Portland Cement) in standard concrete with a more sustainable cementitious material such as industrial by product from Steel industry (Ground Granulated Blast Furnace Slag) in an effort to reduce the overall embodied carbon of the concrete. 70% of the aggregate in this concrete canoe mix has been replaced with a lightweight aggregate made up of small polystyrene white beads. In addition steel fibres have also been added to the mix to increase the tensile strength of the overall canoe however this does make for a prickly ride. Coca Cola was added to this concrete mix to increase the setting of this type of concrete to around 20 minutes as it naturally has a very fast setting time of less than five minutes. This Canoe is one of the heaviest however it is also one of the strongest and contains chicken wire inter-weaved with high tensile steel wire as a reinforcement system. This canoe has the lowest embodied carbon of all the canoes. Martin “GENESIS” by Stephen Greer and Patrick Savage Stephen GENESIS consists of a lightweight Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) reinforced with a basalt mesh. I know I know it is a mouthful, but it is interesting stuff! Read on. The concrete contains steel fibres which provide additional flexural strength and crack resistance. By replacing the traditional UHPFRC aggregate of silica sand with glass microspheres, mix density was reduced from 2400 kg/m3 to 1500 kg/m3. The lowest among all other canoe teams here! So we will definitely win. Average wall thickness is 10 millimetres due to our Rugby training, resulting in a canoe weight of less than 70 kg. With the low density and high performance total embodied carbon for this canoe is 51.4kg equivalent without taking into account the transport of materials. This is much higher than all other canoes. The "GENESIS" was the name chosen in order to signal the beginning of an annual challenge within QUB Civil Engineering and it is hoped that the work put into this canoe will be built upon for years to come. Patrick Special thanks to:- Andrea Fordham, David Cleland, David Hughes, Barry Rankin, Muhammed Basheer Shannon Caldwell, Eddie Moulds, Liz Thompson, Nuala Wilson, Bjoern Elsaesser and Carole Maslowski “Maid of Connor ” by Connor Morgan and Andrew Lofthouse Maid of Concrete used basalt fibres, chicken wire mesh and steel wire to increase the tensile strength and small polystyrene beads to lower the density of the concrete so that it will float. The canoe also has sand, water, cement and GGBS in the mix. Maid of Concrete's mix is the closest mix to traditional concrete, hence why we chose the name. Our canoe was heavier than we had planned but we now discovered the “art of intertia and momentum” and we believe this to be an advantage as the mass will make the canoe travel faster! In order to make the ride very smooth we decided not to add that prickly steel fibre, we used a basalt fibre which looked like a horse hair. The embodied carbon content for our canoe 31.7kgs excluding transport of materials. It is fair to say that we have had several strategy meeting to iron out a race strategy and to compensate for the extra weight of our canoe we worked hard to reduce our combined weight and build extra muscles for an easy ride. We are confident that our canoe will finish within the first two places subject to favourable weather, ideal T-Shirt temperature, oxygen content of river water, smell of bbq and taste of water. “The Red Devil” by Eoghan McManus and Ryan Cherry This canoe consists of low density (1640 kg/m3) cement based concrete, reinforced with steel mesh and basalt fibres, which were mixed in with the concrete during casting. In order to decrease the concrete density, 50% of the aggregate was replaced with lightweight ‘Elemix’ aggregate in the form of small polystyrene beads. The key to the success of this canoe is extensive mix design research as well as the early mornings and late afternoons testing in the lab. The team would like to acknowledge the support provided by Facebook and Google for conducting their research and keeping them socially active while working in the dungeons. Andrew Eoghan The defining feature about this canoe is its very high flexural strength to weight ratio, which will hopefully be the deciding factor in the final race. Canoeist can ride in comfort and do not have to fear a prickly ride or attack from fish. We believe with such a light weight canoe we will be able to finish first and be at the race barbeque first. Ryan joining the canoe race via Facebook As Ryan is away on an IAESTE placement to Palestine, the canoe team consist of Eoghan and Jamie Laing. Geoff, Hilary and Jamie all have contributed heavily to the success of this Concrete Canoe Challenge. Hence we are delighted to have Jamie on board, but he is a bit shy and don’t like being photographed. Jamie Behind the scenes:- Geoff Davis, Hilary Laing, Jamie Laing, Marios Soutsos, James Lim, Adrian Long, Trevor Whittaker, Keith McAllister, John McKinley and Sreejith Nanukuttan