Materials

advertisement

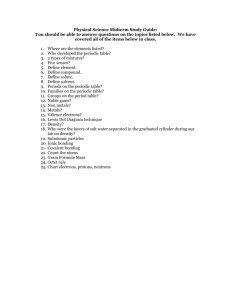

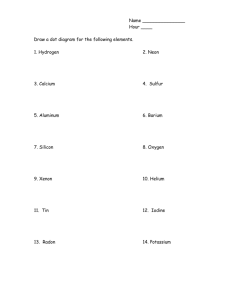

Material Properties 1. Why do pans have non-metal handles? 2. Why is a space shuttle covered in ceramic tiles? 3. Why is cement better in compression and string better in tension? http://www.chiphi-pi.org/b2b/pics/Aluminum_Alloy_Nonstick_Frying_Pan_with_Lid.jpg http://www.cobbk12.org/Russell/images/shuttle_endeavour.jpg Materials 1. Types of Materials 2. Atomic Structure 3. Bonding/Material Structure 4. Bulk Material Properties 5. Material Testing Solids 1. Crystals/Metals (Fe, Cu, Al, quartz) Atoms and molecules are systematically arranged during solidification 2. Glasses and Ceramics (sand, brick, window glass) High viscosity during solidification prevents crystallization 3. Polymers (rubber, plastics, DNA, proteins) Long chains of simple molecular structures. 4. Composites (plywood, cement and rebar) Use of two or more materials to obtain desired engineering properties Atomic Structure 1. What does an atom look like and what are its components? 2. How big are the electrons shells compared to the nucleus? Atomic Structure 1) Composition: A) Nucleus: protons(+) and neutrons(o) B) Electrons(-) 2) ~10-10m across = 0.0000000001m 3) Neutral charge #electrons = #protons 4) Electrons orbit around the nucleus 5) Reactivity with other atoms depends on # of electrons in outermost shell 6) Electrons in outermost shell are called “valence” electrons Bonding Primary Bonding Ionic: transfer of electrons between metal and non-metal ion (NaCl and ceramics) Covalent: localized sharing of electrons (ceramics, diamond, glass, wood) Metallic: delocalized sharing of electrons (metals) Secondary Bonding Van der Waals: weak forces that attract neutral molecules to another other in gases Hydrogen Bonding: attractive force between molecules arising from the interaction between hydrogen atom and N, O, or F http://www.mnh.si.edu/earth/text/2_2_2_4.html http://www.ider.herts.ac.uk/school/courseware/materials/bonding.html Bonding 1. Why are metals ductile and ionic solid (ceramics) brittle? 2. How does a material react to pushing or pulling? 3. How do atoms react to pushing or pulling? Material Properties Stress and strain Hooke’s law Springs, paper clip, silly putty Plastic deformation Necking Stress-Strain Curve What would the stress-strain curve look like for a ceramic material? What about for polymer? How would temperature affect the polymer? Materials Testing Compressive Strength: The maximum compressive stress a material can withstand without failure Crushing or buckling failure Failure depends on the material’s geometry and support Euler buckling load Testing spaghetti Materials Testing Fracture Strength: Bending Test What’s going on in the center of the material? Lab: Measure deflection of spaghetti under a given load. Tensile Strength Test Lab: Measure fracture strength of sample under Charpy V-notch Test Toughness: resistance to fracture of a material when stressed (defined as area under stress-strain curve) Amount of energy absorbed in fracture Classifies material as either brittle or ductile Brittle: absorbs small amount of energy Ductile: absorbs large amount of energy http://www.twi.co.uk/twiimages/jk71f2.gif