Below, you will find an article published in May of 2006 about the

advertisement

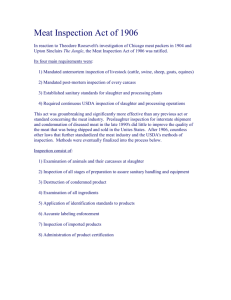

Below, you will find an article published in May of 2006 about the 100 year anniversary of Food Safety and Inspection services in the United States. Read the article and answer the attached questions. This year, the U.S. Department of Agriculture’s Food Safety and Inspection Service (FSIS) celebrates 100 years of protecting the food supply under the Federal Meat Inspection Act (FMIA). FSIS is the premier public health regulatory agency that ensures the safety and security of the U.S. meat, poultry and egg products supply. For the past century under FMIA, FSIS and its predecessors have ensured that meat products are safe to consume by carrying out continuous, daily inspections at slaughter and food processing establishments. The Early Days The genesis of food inspection in the United States stems from a diverse array of local statutes originating in the thirteen colonies. However, the true origin of federal food inspection laws in the United States came from the U.S. Department of Agriculture (USDA). When President Abraham Lincoln signed the legislation creating USDA in 1862, the department’s primary focus was to stimulate food production by providing seed and agricultural information to farmers and help them receive a fair price for their crops. Following the U.S. Civil War, westward expansion and development of refrigerated railroad cars spurred the growth of not only the livestock industry, but also meat packing and international trade. In response to the growing pressure from veterinarians, ranchers, and meat packers for a unified effort to eradicate livestock diseases in the United States, President Chester Arthur signed the Bureau of Animal Industry Act, which created USDA’s Bureau of Animal Industry (BAI) in 1884, effectively the true forerunner of FSIS. BAI’s function was to focus on preventing diseased animals from being used as food. BAI gained further responsibility in 1890 to enforce the newly approved meat inspection act to ensure salted pork and bacon intended for export was safe. In 1891, the Act was amended to cover the inspection and certification of all live cattle for export and live cattle that were to be slaughtered and their meat exported. The Growing Meat Packing Industry However in 1905, the BAI faced its first challenge with the publication of Upton Sinclair’s The Jungle. The ground breaking book exposed insanitary conditions in the Chicago Meat Packing industry, igniting public outrage, which eventually led to the establishment of continuous governmental inspection. President Theodore Roosevelt commissioned the Neill-Reynolds report, which confirmed many of Sinclair’s horrid tales. In response to both The Jungle and the Neill-Reynolds report, Congress passed the Federal Meat Inspection Act in June 1906. The FMIA established four major sanitary requirements for the meat packing industry. The Act required mandatory inspection of livestock before slaughter, mandatory postmortem inspection of every carcass and set explicit sanitary standards for slaughterhouses. Finally, the Act allowed the USDA to issue grants of inspection and monitor slaughter and processing operations, enabling the Department to enforce food safety regulatory requirements. Following passage of the 1906 Act, BAI’s Meat Inspection Division hired more than 1,300 inspectors to carry out inspection activities at 163 establishments. In 1907, BAI employed more than 2,200 inspectors at approximately 700 establishments. In 1910, the Meat Inspection Division established a research center in Beltsville, Maryland. Seven similar laboratories were later created throughout the country. These laboratories were responsible both for developing new testing methods and testing meat and meat products for foreign substances Advancing Food Safety Regulations The 1906 FMIA did not apply to poultry due to low consumer demand at the time. Prior to 1920, consumers typically bought poultry directly from a farm house. This practice lasted until 1920 when an outbreak of avian influenza occurred in New York City, the main hub of poultry distribution in the United States. As a result of the outbreak, many localities implemented their own poultry inspection programs. Demand for poultry products skyrocketed during World War II and thereafter. To ensure the safety of American troops, the U.S. military required its purchasing agents to obtain poultry from establishments that conformed to the military’s sanitation standards. USDA inspected these establishments to ensure regulatory compliance. Shortly thereafter, USDA required that poultry processing plants only purchase poultry from establishments meeting USDA sanitation requirements. This process laid the groundwork for the passage of the Poultry Products Inspection Act (PPIA) in 1957. The PPIA required any poultry products that moved in interstate commerce to be continuously inspected: prior to slaughter, after slaughter, before processing and, if the poultry was imported, at the point of entry into the United States. The PPIA imposed additional requirements designed to protect consumers that mirrored requirements of the FMIA. The law required that plant facilities be sanitary, that there be inspection of slaughtering and processing operations and that product labels be accurate and truthful. In 1946, the scope of inspection was expanded with the passage of The Agricultural Marketing Act, which allowed for inspection of exotic and game animals on a fee-forservice basis. The 1946 Act also provided USDA the authority to inspect, certify and identify the class, quality and condition of agricultural products. Grading and quality identification activities were separated from inspection activities and assigned to the Agricultural Marketing Service in 1981. Under the AMA, FSIS also provides voluntary laboratory services that establishments and others may request the Agency to perform. FSIS provides a range of voluntary inspection, certification, and identification services under the AMA to assist in the orderly marketing of various animal products and byproducts. In 1958, in response to public concerns, Congress passed the Humane Methods of Slaughter Act (HMSA), mandating the humane handling and slaughtering of livestock that are to be sold to Federal Agencies. Twenty years later, the Humane Methods of Slaughter Act of 1978 was enacted. This Act amended the Federal Meat Inspection Act of 1906 by requiring that all federally inspected slaughter establishments adopt humane handling and slaughtering methods. In 1967, Congress passed the Wholesome Meat Act and a year later the Wholesome Poultry Products Act. These acts set a minimum sanitation requirement by which State inspection programs must be “at least equal in rigor to” their federal counterparts. Federal standards were now applied to State inspection programs to regulate products sold in intrastate commerce. Additionally, these acts established concurrent jurisdiction over adulterated meat products between USDA and the Department of Health and Human Service’s Food and Drug Administration. The 1970 Egg Products Inspection Act established federal regulatory authority over the inspection of eggs and egg products. This act mandated continuous egg inspection in plants that produced liquid, frozen and dried egg products to be carried out by the USDA’s Agricultural Marketing Service (AMS). Egg hatcheries and packers were also under inspection but the inspection was not continuous. In 1995, FSIS received the sole responsibility for egg inspection within the USDA. The Food and Drug Administration maintained regulatory authority over shell eggs. Meat inspection activities have shifted among various USDA program areas and divisions since the establishment of FMIA. In November 1953, BAI was abolished and the Meat Inspection Division was transferred to the Agricultural Research Service (ARS). ARS’ Consumer and Marketing Service was reorganized in December 1965 to include the MID and Poultry Division. ARS reorganized in 1971 and transferred meat and poultry inspection functions to the newly created the Animal and Plant Health Service in 1972. In March 1977, the Food Safety and Quality Service (FSQS) was created to perform meat and poultry grading as well as inspection activities that were transferred from APHIS. In 1981, FSQS was reorganized and renamed the Food Safety and Inspection Service. Changing the Way We Do Inspection For more than 90 years, meat inspection was based on organoleptic methods, using sight, touch and smell. But in 1993, a deadly outbreak of the Escherichia coli O157:H7 strain signaled the need for greater controls based on science to prevent foodborne illness and protect consumers. FSIS identified E. coli O157:H7 as an adulterant in October 1994, and began a sampling program to test for the pathogen in federally inspected establishments and retail stores. These programs have proven highly effective. The food safety system employed by FSIS to accomplish its mission has evolved to one in which a science-based framework is used to identify and prevent food safety risks. This framework is known as the Pathogen Reduction/Hazard Analysis and Critical Control Points (PR/HACCP) system. PR/HACCP allows for the use of science and technology to improve food safety in order to prevent the introduction of pathogens in the products we consume. The implementation and verification of PR/HACCP plans have led to a dramatic decline in the incidence of foodborne illnesses. Using 2004 data, the Centers for Disease Control and Prevention (CDC) reported a 42% decrease in illnesses caused by E. coli O157:H7. In its report on 2004 data the incidence of infection with pathogens transmitted commonly through foods, the CDC noted significant declines from the 1996-98 baseline in illnesses caused by E. coli O157 (42%), Listeria monocytogenes (40%), Campylobacter (31%) and Yersinia (45%). Dramatic multiyear reductions in illnesses from E. coli O157 meant the United States was below the Healthy People 2010 goal of 1.0 case per 100,000 persons, according to the CDC. The 2005 data showed that at 1.06 cases per 100,000 persons, the United States is still very close to the 2010 goal. The report attributes the changes in the incidence of these infections in part to the control measures implemented by FSIS and the food industry, as well as enhanced food safety education efforts. Moving Forward in the Next Century For the past 100 years of service under the FMIA, the vital services of the Food Safety and Inspection Service has touched the lives of almost every citizen, every day in America. Today, FSIS is accountable for protecting the lives and well-being of 295 million U.S. citizens and millions more around the world. More than 7,600 inspection program personnel are employed by FSIS who are assigned to nearly 6,000 Federal slaughter and food processing establishments. To meet future realities of food safety and public health challenges, FSIS is moving to a more robust risk-based inspection system that continues to rely on science-based policies. This flexibility will allow FSIS to anticipate, and quickly respond to, food safety challenges before they negatively affect public health. The continued modernization of the inspection system will enable FSIS to meet ever-changing threats to public health. FSIS will continue to further enhance and strengthen the present risk-based inspection system so that we are prepared and well equipped for food safety challenges in the next century. Name ___________________________________________ Journalism Date____________ Mrs. Stephens Directions: Read the attached article and answer the following questions in complete sentences. 1. After reading this article, do you feel that the meat you buy at the store is safe to eat? Why or why not? 2. Describe how meat and food inspection changed from 1844 to the present day. Include the dates and years that changes happen. 3. What challenges do you think the Food Safety and Inspection Agencies will have in the future? 4. Yesterday, we read excerpts from Upton Sinclair’s famous novel The Jungle. Think about all the practices that were being used in the meat packing industry (food coloring and smell additives, searing off rotten parts, grinding rotten meat into sausage, food workers being unsanitary, rats…) What, if any, of these practices do you think may still be used today? Why are these practices still allowed? If you don’t think these practices are still used, how are companies monitored? 5. Do you think that the meat at some stores is better than the meat at other stores? Why or why not?