Marc Neuffer - Connecticut Department of Labor

advertisement

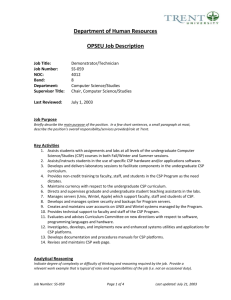

It’s by far the most common question we hear from readers: “How do you get people involved in the safety program?” Of course, there’s no one answer. In fact, we asked several dozen experts for their tips. What works? They offered tips and shared personal experiences — 50 ideas in all. You’re sure to find a few here that will fit your needs. 1. Provide the key elements of knowledge, control and support. Employees use knowledge of their environment to understand what things are putting people in risky situations. Employees need control to make appropriate changes to the system. Finally, workers’ ideas and suggestions need support from management to enable employees to feel they can truly make a difference in the lives of their coworkers. Chuck Pettinger, Ph.D., Project Director, Safety Performance Solutions, Inc. 2. Offer the necessary levels of education, training, resources, and authority so employees can take ownership of the safety process. It’s a mistake to expect employees to take pride and be enthusiastically involved over the long term in order to simply conform to topdown management programs, and/or merely comply with OSHA regulations. The single most powerful source of motivation is employee ownership of the safety process. Earl Blair, Ed.D., CSP, Associate Professor of Safety Education, Indiana University, and owner, Blair Safety Services 3. Focus your training on principles and then work from a critical few principles of the safety process. Ask employees, “How do you want to apply these?” You’ll be far better off using this approach. It stimulates internal commitment, responsibility and accountability. Performance is always better when energized out of commitment versus compliance or obligation. Bob Veazie, past change-agent for safety, Hewlett Packard Inkjet Business 4.Include a safety information column that addresses one safety topic in each issue of your company newsletter. Marc Neuffer, retired nuclear propulsion naval officer, currently director of www.SafetyInfo.com 5. Sponsor “The Day of the Pig” On this day any employee can bring any environmental health and safety-related problem to the forefront freely and without fear of fault-finding or retribution. With management backing, each item is reviewed and a response or resolution is proposed. Items are tracked to completion. Skipper Kendrick, Manager, Industrial Safety & Hygiene, Bell Helicopter Textron, Inc. 6. Protect employees’ voices. Workers who complain about workplace safety or health hazards are frequently the targets of reprisals by their employers. A 1997 Department of Labor report documented that workers who brought complaints directly to their employers first were particularly vulnerable to reprisals. Job termination was documented to be the most frequent discriminatory act taken by employers against workers. An independent voice is also essential because health and safety involves issues of economics and control — issues that management and the workforce may each view very differently. Those who bear the risks should have a significant voice in decisions regarding those risks. Nancy Lessin, Health and Safety Coordinator, Massachusetts AFL-CIO 7. Get workers involved in making decisions about safety. Their input into safety procedures, selection of PPE, and other decisions that affect their own personal safety is paramount. You can do this through a Safety Action Team. Delegates are selected by the employees or are volunteers. My favorite team members are the ones who are outspoken. This team is guided by the safety professional and top manager in the company, but it is not directed by them. Team decisions can be overruled, but you need a good reason and a full explanation. George M. Shirley, safety consultant, Sulphur, La. 8. Give employees something meaningful to do. Identify champions from the management and employee ranks. Involve them in problem-solving, safety observations, workplace inspections, and in training. Communicate the results widely and cultivate a culture that values and rewards these efforts. Gayla J. McCluskey, CIH, CSP, ROH, QEP, Principal, Global Environmental Health Services 9. Go out and ask for their involvement Don't wait for it to happen. Actively search for opportunities to involve employees. Listen up. Pay attention to what employees have to say. Respond to and resolve issues brought forth by their involvement. Skipper Kendrick 10. Ask employees how they would like to be involved. All this may be simpler than we think. We train people on specifics — way more than these smart people need to be told. Let’s get out of the way, and begin asking more questions about how they want to create their safety system and account for their results. Let’s do this instead of telling them what to do. Ask more questions about how your people want to manage safety. Bob Veazie 11. Remember the three-term contingency of applied behavior analysis • Activator • Behavior • Consequence Activators direct Consequences motivate. At first, people need education, training and coaching to know what to do and to expect beneficial outcomes. Through interdependency, trust, and ownership, participants internalize the three-term contingency and hold themselves accountable to actively care. E. Scott Geller, Ph.D., Senior Partner, Safety Performance Solutions, and Professor, Virginia Tech 12. Set up a committee. • Verizon Communications, the national telecommunications company formed by the merger of Bell Atlantic and GTE, is in the process of establishing an Environmental and OSHA Steering Committee. The committee’s role is to establish compliance assessment priorities; review and address assessment results; and review and resolve any resource issues or areas of concern in maintaining compliance and preventing accidents. This committee will meet a minimum of two times a year. It is made up of senior manager members from lines of business where our work exposes the company to the most risk. • Connie S. Lawson, MS, BSN, RN, COHN-S/CM, CHES, CUSA, Director, Disease Prevention and Safety, Health & Environment Promotion, Verizon Communications 13. Start every group meeting with a “Safety Share.” It doesn’t matter whether the topic is production, marketing or quality. Ask participants to report something they have done for safety during the past week or since the last meeting. This gives safety special status and integrates it into every aspect of business — with the focus on achievement. It also gives people the chance to recognize the many things they do daily to keep each other safe. E. Scott Geller 14. Share power. At Newfoundland Power, employees and management share joint ownership of the annual safety strategy, developed each year and undertaken with the direct input of all employees. Strategy sessions are lead by the manager and coordinated by the joint occupational health and safety committee. It is a shared responsibility. The strategy lays out a full 12 months of prevention initiatives. As one employee said, “We do best what we plan best.” Wayne Pardy, President, Pardy Associates, St. John’s, Newfoundland 15. Hold a summit. As a follow up to a recent employee perception survey, a “Safety Summit” was convened. A cross-functional group of employees and management met off-site to discuss the top three issues from the survey. The summit was kicked off by a member of senior management. Participants were then asked to list what was working in each of the three areas of concern. Then they listed opportunities for improvement and specific actions to drive change. Employee representatives and supervision presented a summary of the summit results and action items to the Executive Steering Committee for approval and support. Skipper Kendrick 16. Be real. Don’t confuse true worker involvement with sham programs such as company-dominated health and safety committees, which are illegal under section 8(a)(2) of the National Labor Relations Act. Resist enticements to introduce programs that focus on worker behavior rather than identifying and correcting hazardous conditions. Shun programs that discourage injury/illness reporting by offering rewards to workers who don’t report injuries or threaten discipline to those who do. Nancy Lessin 17. Constantly sell your program and constantly improve your program. Every conversation with your management or workers in the field is a potential opportunity to sell the benefits of your program. Doan J. Hansen, Ph.D., MPH, CIH, Department of Energy SCAPA Technical Coordinator, Brookhaven National Laboratory, Upton, N.Y. 18. Manage by walking about Get to know employees and their concerns. Let them get to know you. Marc Neuffer 19. Ask for insight. Managers often ask people to conduct safety tours or to do behavioral observation counts, but they rarely ask about what people found when they looked. This says safety is not interesting. Make a point to ask for trends, patterns, and overall conclusions such as, “We take care of guards on equipment but we often miss problems related to the condition of the floor.” People like to be reinforced for being perceptive. Betty Loafmann, President, Advanced Performance Technologies – Safety Systems 20. Ask yourself, “How do I get employees involved in the rest of our organization’s activities?” Getting involvement in safety is not likely to happen unless there is also a climate of involvement in other objectives of your organization. Trying to manage safety by involvement, and other activities in other ways, is not likely to work, at least not consistently. Typically, other company interests can benefit from an involvement approach as well. It’s been said that, “If you can manage safety, you can manage anything.” Organizations can learn a lot about what they need to do overall by seriously examining how to effectively manage safety through energizing their people in safety processes. Once managers recognize the benefits and involvement becomes expected, participation in safety is more readily achieved Dan Markiewicz, MS, CIH, CSP, CHMM, environmental health and safety consultant, Toledo, Ohio 21. Answer the question, “What are you doing now to keep employees out of safety?” Employees are already motivated to improve safety. Their motivation is a natural instinct; they have seen what can happen when safety is compromised and they don’t want it. They do want a safe working environment. The difficulty comes when barriers are inadvertently constructed that de-motivate the employee. Barriers are things like incentives, not listening to the employees’ view, sending mixed messages about the real importance of safety, having mixed support within management, poor quality safety meetings, poor communication — all the things we know are important but don’t know how to maintain effectively. Lack of employee motivation is a symptom, not a cause. Thomas R. Krause, Ph.D., Co-Founder and Chief Executive Officer, Behavioral Science Technology, Inc.® 22. Ask senior line management this question: “How can safety help you meet your important business objectives?” When asked with sincerity, this question can change management’s perspective of safety. Rather than a staff cost necessity, safety is seen as a business-building asset, a new business partner. To get senior line managers involved, play in their sandbox; don’t expect them to play in yours. Rick Fulwiler, Sc.D., CIH, President, Technology Leadership Associates 23. Enhance your relationship skills. Be recognized as trustworthy and display confidence in the ideas you want promoted. Management and employees will not eagerly support merely an idea or program, but they will support someone they like and trust. It takes a leader, in the true sense of the term, to bring along followers and supporters. Dan Markiewicz 24. Build trust in yourself and your message. This must happen before anything else. People must understand that your core purpose is to assure worker health and safety. It’s not about you, it’s about them. Then you need to get champions from management, unions and employees to believe. You need to keep the urgency so people perceive the importance of your message. Keep them thinking holistically and viewing safety and health as a system. Hank Lick, CIH, CSP, Ph.D, Director of Industrial Hygiene, Ford Motor Co. 25. Solve problems. People remember those who helped them out. Any problem left long enough will become a safety problem. Unfortunately, you’ll have plenty of opportunities to solve problems. Being known as a problem-solver is one way to get people on your side. Roger Simpson, CSP, CHMM, Safety and Environmental Director, Shelby Williams, Morristown, Tenn. 26. Treat employees with respect, honesty and fairness. You get employees involved in safety the same way you get anyone to do anything. Work to find out what they want, then respond in meeting their needs and addressing their concerns. This requires leadership and partnership, and it is irresistible. Molly McClintock, Ph.D., Senior Partner, Safety Performance Solutions, Inc. 27. Use pay envelope stuffers — a small slip of paper thanking employees for their efforts in safety. Marc Neuffer 28. Demonstrate to hourly employees and staff that the safety process is working. They have to see that it’s working. Often, it’s up to one individual to start this process. Take a credible, realistic position on safety. Express “zero tolerance” for non-compliance with your work standards and procedures, and provide a method for modifying them. Finally, recognize informally and/or formally efforts toward compliance. Ernie Huelke, CSP, CHMM, RPIH, Safety Manager, O’Hare Airport Transit System, Chicago, and owner of the consulting firm, SafetywoRx 29. Show results. When people begin to see positive results by eliminating hazards, they all want to get on board and you end up with a waiting list of employees ready to contribute to safety committees and other activities. I’ve learned that everyone wants to be part of a winner and no one wants to be part of a loser. Mark D. Hansen, CSP, CPE, PE, Director, Quality, Health, Safety & Environmental, Weatherford International, Inc., Houston, Texas 30. Give people the feeling that they will have an impact. Listen well. We received 29,000+ suggestion, near-miss, unsafe act and condition reports last year — an average of ten per person. Why? Because employees could see a process that assured 100 percent of their reports would be taken seriously. Kyle B. Dotson, CIH, CSP, PE, Occupational Health and Safety, BHP, Houston, Texas 31. Start at the beginning. You must have the basics of workplace safety in place, including high levels of the following: management involvement, engineering for prevention, environmental health and safety compliance, and an effective system to address hazards. The overall culture should be one that encourages employee participation. Earl Blair 32. Go back to the most basic fundamental: What the boss is interested in, everyone else will soon be interested in as well. We call it “management support,” and employees can tell whether it exists or not in a New York minute. There is no substitute, and there is no success without it. Dan O’Brien, CSP, Safety and Health Manager, Engineered Carbons, Inc., Borger, Texas 33. Gain a clear understanding of your enterprise’s critical outputs to gain management’s involvement. Then identify the direct linkages that safety outputs can have with these critical enterprise outputs. Once the linkages are identified, start expressing safety outputs in terms of the business outputs. For example, express injury and illness or workers’ comp costs in terms of sales equivalent dollars [$ equivalent sales = injury/illness costs as $ X 100% / profit margin as %] or a reduction in repetitive motion disorders as an increase in productivity. This will gain the attention of senior line management and their involvement will follow. Rick Fulwiler 34. Get managers at the top to realize the need for excellence in safety. To get their attention, it’s often better to have some type of objective assessment that comes from the corporate level or from outsiders. This could involve employee sensing sessions, climate surveys and programmatic reviews. As we all know, prophets are not often heard in their own land, and so it is with safety professionals. An outside perspective can provide leaders with a new perspective regarding other organizations that are pursuing safety excellence. David J. Sarkus, MS, CSP, a safety and health consultant in Monongahela, Pa., and ISHN’s Technical Editor 35. Assess your corporate culture. In positive cultures, you can build relationships and trust, partnering with management and employees alike. In negative cultures, try to show employees that you are here to ensure a safe workplace by eliminating hazards through engineering design, training and safe work procedures. Mark D. Hansen 36. Show management commitment in small and multiple ways. This is critical. Involve management at all levels in audits and inspections. Be sure managers are visible and engaged in training. Include safety and health issues in all management presentations. Be sure that follow-up on safety and health issues and audit items is part of the management review process. There must be consequences at all levels for nonconformance to agreed-upon policies and procedures. Thomas G. Grumbles, CIH, CONDEA Vista Company, Houston, Texas 37. Reinforce managers in regular staff meetings for what they personally did about safety this month. This moves safety from a set of boring statistics that include luck to an aspect of management that can be a source of pride. Betty Loafmann 38. Expect accountability. At RailWorks, a newly created corporation comprised of 35+ railroad construction, maintenance, manufacturing and supply companies, operations within a group with high claim counts are financially penalized for abovegroup-average claim costs. Credits are given to operations with better-than-group averages. The current average claim cost is used as the multiplier in this “zero based” budget program where debits = credits. Also, safety is a “first agenda item” of staff and management meetings and an integral item of our executive incentive (bonus) program. Jeffrey D. Meddin, CSP, CHCM, WSO-CSE, Corporate Director of Safety, Railworks Corporation, Baltimore, Md. 39. Give supervisors information and tools. Each week or twice each month slip a “Supervisor Safety Topic” sheet in each supervisor’s in-box. They’ll read it on their own time. Marc Neuffer 40. Build safety into the core of your business. Safety unto itself as a program that “everyone should be involved with” won’t work. It has to be an integrated part of your entire operation. When processes, procedures, training programs, operations manuals, supervisory training programs, and management planning sessions all contain aspects of safety, everyone will become “involved in safety.” It’s not a matter of how to get individuals involved. It’s a matter of involving safety in the conduct of your overall business. Earl DelGrosso, Director, Environmental Affairs/Safety Services, Treasure Chest Advertising Co., Inc., Baltimore, Md. 41. Don't build new structures if the existing ones are already successful! Find out what existing management systems make your company successful. Then brainstorm with a cross-section of the company — hourly workers to senior management — to determine how to inject environmental health and safety into those systems. Systems (generally non-EHS) that people use everyday, and that are part of the culture, are the best vehicles for getting people involved. R. Birkner, MBA, CIH, CSP, Vice President, McIntyre Birkner and Associates, Inc., Thousand Oaks, Calif. 42. Design your safety approach to be practical … so that everyone sees it as reasonable and useful. Help others become truly enthusiastic about safety based upon their getting positive benefits. This has to go beyond “do this so you don’t get hurt.” Employ a “scissors” approach that simultaneously enlists management top-down and line workers bottom-up. Plan beyond an initial intervention. All involvement has to be fed and maintained in order to build momentum and enhance credibility. Robert Pater, Strategic Safety Associates, Portland, Ore. 43. Keep it simple. A safety mission or program should be simple and respectful. Our lives are so complicated and stressful, a simple safety plan, administered and demonstrated by management in a concise manner, will have employees buying into it better than a complicated or ambiguous safety mission or program. Ron and Dot Hayes, co-founders of The Fight Project, Fairhope, Ala. 44. Design a one-page “Safety Flash” that covers not only workplace safety but also home and recreation safety tips. Scatter them around the company lunchroom tables, or place them in a rack by the vending machines. Marc Neuffer 45. Discuss your OSHA recordable rate. A rate of ten, for example, means that ten out of every 100 employees will be hurt seriously enough to require medical attention this year. Remind everyone that the rate is based on all of your employees, including office workers who are less likely to be hurt. For the more hazardous jobs, the OSHA recordable rate may actually be as high as 30. This means that an employee could expect to be hurt seriously enough to require medical care three out of every ten years of their employment, or nine times in a 30-year career. Ask your employees if they would want their son or daughter to work at a company where they could be seriously hurt nine times in their career. This discussion usually causes a few employees to all of a sudden see the light and want to change the world. These are the people you want on your safety team. You need them to help you convert the majority of employees who don’t care about safety one way or the other to your side. Gary Higbee, Manager, Health, Safety & Environmental, The Budd Co., Stamping & Frame Div., Rochester, Mich. 46. Find your true believers. The best salespeople are those who are convinced that safety works to keep them safe. Have an employee whose sight was saved because he wore safety glasses give a talk. He’ll motivate his fellow employees to get involved. Barry R. Weissman, REM, CSP, CHMM, Regional Manager-Safety, Health & Industrial Hygiene, EA Engineering, Science and Technology, Inc. 47. Provide positive consequences for desired behaviors and actions. People only work to receive positive consequences or avoid negative ones. Safety programs typically motivate people to avoid negative consequences, such as injury or discipline. A new way to define and measure desired safety performance is needed. These new expectations must be clearly communicated and understood by all. Then, positive reinforcement must be provided when those desired behaviors occur. This does not mean trinkets or giveaways, but sincere acknowledgement from peers, supervision and management. When this happens, employees will be motivated to be involved in any safety program. Robert Ryan, CSP, President, Safety Metrics, Inc. 48. Have managers set clear safety expectations for the organization, with your input. Managers, not you or other safety personnel, should communicate these expectations to the organization. Managers must then visibly support these expectations during facility tours, meetings and one-on-ones. They should track progress and hold the organization accountable for meeting the expectations. They should also recognize and reward progress and performance. Many times senior line managers do not get involved with safety because they simply don’t know how or what to do. Their roles need not be complicated or extremely energy intensive. Rick Fulwiler 49. Develop a vision for safety. This vision should get employees excited about moving toward excellence in safety. Along with this vision, management must provide opportunities for learning that go beyond compliance activities or the basics. These learning opportunities must create a high-trust culture. Within this culture people must be given opportunities to fail and succeed, realizing that they are being empowered to move toward “their” vision of excellence for safety. J. Sarkus 50. Get everyone on the same page. Executives, supervisors, employees and the safety and health team must have the same vision for safety and health. Everyone must understand that safety and health really are important to each level of the organization, and that the employees’ wellbeing is what it is all about. There can be no hidden agendas, no “gotchas.” Employees’ concerns and their ideas and suggestions are to be taken seriously, sometimes implemented, and rewarded. This is not a difficult mission, but it does take discipline to keep on track. Margaret M. Carroll, CSP, PE, Sandia National Laboratories, Safety Engineering, Albuquerque, NM