Effects of the magnetic field in Nickel electrodeposition

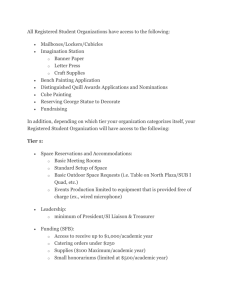

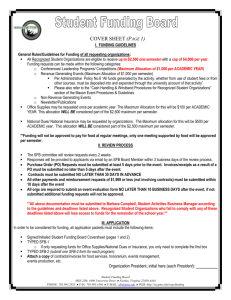

advertisement

Influence of static magnetic fields in nickel electrodeposition Adriana Ispas, Andreas Bund, Waldfried Plieth SFB 609 Outline •Fundamentals -electrodeposition -Electrochemical Quartz Crystal Microbalance (EQCM) •Results –current efficiency –hydrogen evolution –morphology aspects –magnetic properties Nickel sulphamate electrolyte (pH= 4) : 1.26 M Ni(SO3NH2)2*4H2O ; 0.32 M H3BO3 0.04M NiCl2*6 H2O; 5.2*10-4 M Sodium Dodecyl Sulphate (surfactant) SFB 609 Electrodeposition After introducing a metal electrode in an aqueous solution of its ions, will be established a thermodynamic equilibrium, manifesting itself as a potential difference (ΔΦ0) between the electrode and the electrolyte. ΔΦ0 depends on the type of metal electrode and also on the concentration of metal ions. Faraday showed that the electrodeposited mass is equivalent to the electrical charge that passes the interface electrolyte/electrode. The current is maintained by the following equation M z ze M (1) Furthermore the following two equations can be relevant for electroplating: (2) H e 1/2H 2 (3) O 2 H 2 O 2e 2OH SFB 609 Electrodeposition Conway and Bockris made fundamental research about the •manner in which the hydration sheath is stripped from the metal ion •ion is incorporated in the lattice 1. 2. 3. 4. 5. Ni2+ (hydrated in solution). It diffuses to the electrode. Ni+ (hydrated, at electrode). It is transferred to the electrode surface Ni+ (partially hydrated, attached to the electrode surface as an “adion”). It diffuses across the electrode surface to a crystal building site. Ni+ (adion at crystal building site). It becomes a part of the lattice. Ni++e-Ni. The nickel becomes incorporated in the lattice „adion“the entity that results from transfer from the solution side of the double layer to the electrode. The ion retains part of its chargetherefore it is an adsorbed ion SFB 609 Cathodic behavior of Nickel Ni2+ +2e– Ni Cathodic reactions: 2(H++ e–) H2 1. 2. 3. 4. 4‘. Ni2+ Ni+ads Ni+ads 2H *ads Ni+ads Ni+ads Ni e– Ni+ads + H*ads H2 + H*ads +H+ +e– Ni + H2 + e– + e– + H+ + Ni–HadsNi(Hads) H.W. Pickering et al., J. Electrochem. Soc. 144 (1997) L58 SFB 609 Electrochemical Quartz Crystal Microbalance film gold electrodes Sauerbrey equation: f 2 f 0 2 m A q q 10 MHz polished quartzes, AT-cut 1/ 2 shear motion quartz (μq = shear modulus [g/cm s2]; ρq = density of the quartz [g/cm3]; A =piezoelectrically active area) SFB 609 Equivalent circuit of a quartz crystal M= mass Cm= compliance (equivalent to 1/k; k: Hooke‘s constant ) r= coefficient of friction of a piston The mechanical model of an electroacoustical system Lm=inertial component, related to the displaced mass (m) during oscillation Cm=compliance of the quartz element representing the energy stored during oscillation Rm =the energy dissipation during oscillation due to internal friction, mechanical loses and acoustical loses ZM,L =mechanical impedance Butterworth-van Dyke model SFB 609 What predicts the theory? Force acting on moving ions in the solution : F q E v B FL j B j Cq v Cq v E=electric field v= velocity B= magnetic field μ= mobility of ions in solution C=concentration of anions/ cations SFB 609 Disk electrode μ 10-8 m2 v-1s-1 q= electric charge B1T v μE Magnetic field causes stirring: F ΔV B I Theoretical approach Cauchy‘s equation: v ρ ρ v v P τ i B t P- gradient of the pressure i B Lorentz force τ - frictional forces, - the stress tensor Nernst-Planck equation i j D jC j z jF RT D j CjΦ C j v SFB 609 Dj – diffusion coefficient Cj –concentration coefficient Theoretical approach Paramagnetic force (in electrolytic solutions with paramagnetic ions): Fp χ m B2 C 2μ 0 m -the molar susceptibility, C –concentration -the vacuum permeability, 4•10-7 H.m-1 Force due to the gradient of the magnetic field F χ m B B C μ0 Navier-Stokes equation: v 2 ρ ρ v v P η v i B F B F C t Magnetic field effects in electrodeposition are non negligible just in the case when they are combined with the convective movements in the solution J.M.D. Coey, and G. Hinds, Journal of Alloys and Compounds, 326 (2001) 238-245 SFB 609 Experimental set-up Reference Electrode Hg/ Hg2Cl2 RE CE WE Counter electrode N Computer Potentiostat S Cell Working electrode Quartz Network analyser SFB 609 Mechanical vs. magnetical stirring 96 92 90 i=-0.5A.dm 88 94.5 -2 86 84 82 80 0 100 200 300 rot/min 400 500 600 current efficiency / % current efficiency / % 94 -2 i=-0.5A.dm 94.0 93.5 93.0 92.5 -100 0 100 200 300 400 500 600 700 B / mT SFB 609 Current efficiency Calculation of the mass deposited given by Faraday’s law M= atomic mass (58.69 g/mol for Ni) F= Faraday constant (96485 C/mol) z =valence of species (2) A=active aria of the electrode i=electric current 1 dm Mi A dt nF η current efficiency / % Side reaction occurs current efficiency of Ni electrodeposition goes down 98 dm/dt meas dm/dt calc -2 i=-0.01 A.dm 96 94 92 90 88 0 100 200 300 B / mT SFB 609 400 500 600 Hydrogen evolution dQ i total dt Fz dm i Ni M dt i total i Ni i H 2 -2 i total = -0.05 A.dm 0.011 itotal= -5A.dm 1.0 -2 0.010 nichel sulfamate bath ( with surfactants) -2 itotal= -0.01A.dm 4 iH2 (B)/ iH2(B=0T) 2 0.7 iH2 (B)/ iH2(B=0T) 0.8 iH2 / A.dm -2 0.009 0.9 0.007 0.006 0.005 0.004 0.6 0 0 -100 nichel sulfamate bath ( without surfactants) 0.008 0 100 200 300 400 500 600 700 800 100 200 300 400 B / mT B / mT SFB 609 500 600 700 Damping of the quartz during Ni deposition -2 0 mT 206 mT 740 mT 4 3 2 itotal= -0.01A.dm 0 mT 206 mT 410 mT 530 mT 20 1 0 -1 -50 2 25 0 50 100 150 200 250 300 350 400 time / s Damping Rm / W Damping w / kHz 5 itotal = -5A.dm 15 10 5 0 0 500 1000 1500 2000 2500 3000 3500 time / s SFB 609 Morphology- preliminary results B= 0 mT, i=-5 A dm2 i(H2)=-1.29 A dm-2 Small damping change AFM type PicoSPM, version 2.4 The tip of the cantilevers were pyramidal shape, made of silicon nitride SFB 609 B= 740 mT, i=-5 A dm2 i(H2)=-0.78 A dm-2 Large damping change Roughness Rq Ra 2 Z Z i ave N 1 LxLy Ly Lx f x, y dxdy 0 0 Rq is the standard deviation of the Z values within the given area, calculated from the topography image (the height) Zi is the current Z value Zave- the average of Z values within the given area N- number of points from the given area Ra is the mean roughness Lx, Ly are the dimension of the surface f(x,y) give the relative surface to the central plane B (mT) 0 530 740 Ra (nm) 5.14 23.26 26.93 standard error 1.18 2.44 2.48 Rq (nm) 6.55 29.66 34.05 standard error 1.51 2.39 2.29 SFB 609 Magnetic properties of deposited Ni layers 20 degr 40 degr 60 degr 80 degr 100 degr 120 degr 140 degr 160 degr M/Ms 0.5 0.0 -0.5 -1.0 0 degr 20 degr 40 degr 60 degr 80 degr 100 degr 120 degr 140 degr 160 degr 1.0 0.5 M/Ms 1.0 0.0 -0.5 -1.0 -10000 -5000 0 5000 10000 -10000 H (G) -5000 0 5000 H (G) B= 0 mT B=700 mT SFB 609 10000 Summary • EQCM is a useful tool for the in situ investigation of the deposited mass and of the current efficiency • Changes in morphology of the deposited layer in the presence of a B field parallel with working electrode • Magnetic field influence the roughness of the deposited layer and the lateral reactions of electrodeposition process SFB 609 Acknowledgments • Special thanks to Dr. Stefan Roth for the VSM measurements • Thanks for the moral support to AK Plieth • Many thanks to DFG for the financial support SFB 609