11.03-Essa Ahmed-Sultan Ahmed-Omar Ibrahim

advertisement

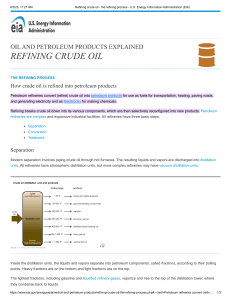

Created by: Essa Ahmed Ali Sultan Ahmed Sultan Omar Ibrahim Saleh Section: 11.03 Fractional distillation is done in petroleum refineries, chemical plants and natural gas processing plants. It is a continuous steady task, as input and output is a constant process. The fractional industrial distillation is normally done in huge, vertical columns called fractionating towers. They are also called distillation columns. is the separation of petroleum products into a separate component according to their boiling points where the lowest boiling point liquid will be distilled 1st. heat source, such as a hot plate with a bath, and ideally with a magnetic stirrer. distilling flask, typically a round-bottom flask receiving flask, often also a round-bottom flask fractionating column distillation head thermometer and adapter if needed condenser, such as a Liebig condenser, Graham condenser or Allihn condenser vacuum adapter (not used in image to the right) boiling chips, also known as anti-bumping granules Standard laboratory glassware with ground glass joints, e.g. quickfit apparatus. It is a manufacturing process that separates the different components in a chemical mixture according to their different boiling points. The liquid is raised to boiling and vapors pass through a tubular column where temperature is gradually lowered along its length. Components (fractions) with a higher boiling point condense on the column and return to the solution. Fractions with a lower boiling point pass through the column and are collected. Gasoline, kerosene and naphtha are fractions separated from crude oil using fractional distillation. a) Light Distillates Naphtha, Kerosene b) Middle Light gas oil, Heavy gas oil c) Residue further processed into refinery fuels, heavy fuel oil, waxes, greases, asphalts [the lighter the stuff the higher the price] The components of crude oil are petrol, tar, oil, dissolved gases and kerosene also known as petroleum. The oil we find underground is called crude oil. Crude oil is a mixture of hydrocarbons - from almost solid to gaseous. These were produced when tiny plants and animals decayed under layers of sand and mud millions of years ago. Crude oil has to be changed before it can be used for anything. This happens in an oil refinery. Crude oil doesn't always look the same – it depends where it comes from. Sometimes it is almost colorless, or it can be thick and black. But crude oil usually looks like thin, brown treacle. Crude oil is a naturally occurring liquid composed mostly of hydrogen and carbon. It is usually found underground but can also be found above ground in oil seeps or tar pits. Crude oil is used to produce fuel for cars, trucks, airplanes, boats and trains. It is also used for a wide variety of other products including asphalt for roads, lubricants for all kinds of machines, plastics for toys, bottles, food wrap and computers. Crude oil is believed to have been formed from very small plants and animals that lived in ancient seas and oceans a very long time ago. As these plants and animals die, they sink to the bottom of the sea where they mix with mud, sand, and clay. Petroleum can be separated into different fractions by fractional distillation. Petroleum is heated to 360C in the absence of air in a furnace to vaporize it before fractional distillation. Crude oil is a naturally occurring liquid composed mostly of hydrogen and carbon. Crude oil is usually found underground. Google Wikipedia The chemistry book