Amway Lean Office Presentation

advertisement

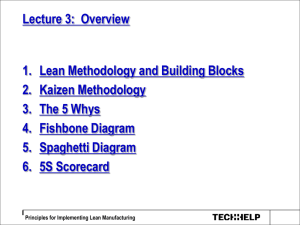

Amway’s Lean Office Journey West Michigan HDI October 10th, 2012 Agenda • Welcome Jill Bierens – Manager, Global IT Service Desk • Lean Office Overview Stephen Sweers – Manager, OPX Lean Office • Amway IT Results David Drake – Lean Leader, IT Jill Bierens Daniel Uecker-Herman – Lead Service Desk Technician • Q&A • Optional Tour: IT Operations, ITAM, Lean Cell About Amway • Founded in 1959 • Second largest direct-selling company in the world Annual sales of more than $10 billion in 2011 More than 450 products 80 countries and territories 20,000 employees Six million entrepreneurs selling Amway products around the world More than 900 patents granted and more than 800 pending The Heart of Amway Amway’s Global Service Desk • Metrics Nearly 6,000 customers in North America and SE Asia Average 13,000 incoming contacts per month (all channels) Average 5,000 calls per month Live answer = 85% First Contact Resolution = 75% Eight Service Desk Technicians Four User Management Technicians Amway’s Global Service Desk • Current State Caller Ada HQ 6:30am–7:30pm Malaysia 7:00am-7:00pm • Strategy • Four regions • Follow the Sun • Standardized processes IT Operations Weekends & Holidays WHY LEAN OFFICE? • Identify and eliminate wasteful process steps in a systematic way • More than 60% of the cost of a product or service is attributable to administrative processes. • Quality and service improve • Turnaround time shortens • Costs go down and profits go up • The customer is ultimately delighted • Resources (people and money) become available to be redeployed to further grow the business KAIZEN DEFINED Whipped Back Sheep Self Altar Kai “change” (revolutionary) zen “good” (sacrifice) LEAN OFFICE ISSUES • • • • Quality: How to improve it? Cost: How to reduce it? Delivery: How to ensure it? Talent: How to develop it? ELIMINATE WASTE • The 8 Wastes Defects Over-production Waiting Not engaging people Transportation Inventories Motion Excess processing ELIMINATE WASTE • Unevenness Can often be eliminated by managers through level scheduling and careful attention to the pace of work. • Overburdening Workers by requiring them to operate at a higher pace, with more effort and for a longer period of time than appropriate workforce management allows (target utilization @ 85%). TRUE NORTH METRICS • • • • Right 1st time Quality Improvement Delivery/Lead Time/Flow Improvement Cost/Productivity Improvement Talent Development “These are a select few measures, and if you improve them each year, ‘good things’ will happen.” – George Koenigsaecker LEADERSHIP BEHAVIOR Critical Questions Traditional Management Lean Management What is a problem? The result of someone messing up A deviation from Standard What is the cause? The “Individual” (“5 Who’s”) The “System” (“5 Why’s”) Who is responsible? The person who makes the mistake (5% of the time) Management (95% of the time) What should the individual who makes a mistake do? Solve the problem on your own if at all possible Call attention to the problem for assistance, to learn & to avoid the problem in the future What are the assumptions about people? People will not accept blame unless forced to People will feel empowered if they receive positive support for solving problems Problem Solving Skills Some have it, some do not It can and must be taught THOUGHT-PROVOKING QUESTIONS • To what extent are your Function’s goals linked to Enterprise Goals? • Can you identify all of your Function’s internal and external customers? • Do you know all of the products and/or services your Function provides its customers? • Do you know your customer’s requirements for your Function’s products and/or services? • Do you measure Functional performance on the basis of how well your products and/or services meet your customer’s requirements? • Can you identify your Function’s internal and external suppliers? • Do you establish clear goals for the products and services provided to your Function by your suppliers? • Do you have documentation of your Function’s role in the cross-functional value streams to which it contributes? • Do you measure your Function on the degree to which it contributes to cross-functional value streams? • Do you measure the “upstream” performance of the processes that flow through your Function? • Do you have tracking and feedback systems that effectively and efficiently gather performance information and provide it to the people who need it? • Do you have the skills to troubleshoot (remove the root causes of) performance gaps in your systems? • Do you spend a large percentage of your time working to improve the interfaces between your Function and other Functions and between subunits within your Function? • Do employees in your Function work in an environment where their job design, job goals, feedback, rewards, resources and training enable them to make their maximum contributions to process efficiency and effectiveness? SUCCESS FACTORS Factors for success: • • • • • • • Clear Business Case Leadership Endorsement Clear Roles & Responsibilities Dedicated Internal Resources Structured, Systematic Method Simple, True North Metrics Frequent Reviews DEPLOYMENT MODEL: PHASE 1 “STABILITY” What: • • • • • Improve Internal Process Workflows and Reliability Standardize Work Processes Improve Process Throughput Time Reduce Clerical Errors (implement mistake-proofing techniques) Establish “Lean Plans” Where: • Transactional Business Processes (ex: Idea-to-Market, Procure-to-Pay, etc.) • Key Functional Areas (ex: Planning, Procurement, QA, R&D, IT, Sales, Finance) Impact on: • Throughput Time Variation (Operational Lead Time Improvement) • Right 1st Time Quality Improvement LEAN OFFICE SPECIALIZATION: INSTABILITY OFFICE EMPLOYEES SPECIALIZATION Breadth of Knowledge Employees typically retain 80% of the process knowledge. • • • • Specialized work No level loading Work duplication No realization of waste LEAN OFFICE SPECIALIZATION: STABILITY OFFICE EMPLOYEES GENERALIST Shared Knowledge • Multi-Skilled • Multi-Process Handling • Level loaded @ 85% of Capacity Skills/Training Matrix LEAN LEADER STANDARD WORK • Assess efficiency of Functional & Cross-Functional business processes. • Develop Functional “Lean Plans” aligned with Enterprise Strategy. • Enable improvement by providing kaizen breakthrough method & support. • Create expectation for annual improvement in: • • • • Right 1st Time Quality Productivity (Cost) Delivery (Lead Time) Talent • Encourage active sharing & adoption of best practices. GETTING STARTED: ACTIVITY 1. What are the top 2 or 3 most costly outputs (products or services) your “lean office” makes and delivers to your customers? Or, what causes you the most pain? Brainstorm! 2. Select one output (product or service for your customer), assemble a team and together explore using the SIPOC Tool (Supplier/Input/Process/Output/Customer). 3. Plan your 3-5 Day Kaizen Event using your completed SIPOC as a guide (hint: you may want to include the voices of suppliers, processors, customers and “outside eyes” as well). 4. Execute the Kaizen Breakthrough Method…. again, again and again (5X)! SIPOC Supplier • Meijer • Kitchen Inputs (Requirements) • 36 Minutes Total Time • 2 ea Eggs • ¼ Cup Water • ½ Cup Vegetable Oil • 8” X 8” Pan • Shortening or Cooking Spray • Large Mixing Bowl • Wire Whip or Large Spoon • Electric or Gas Oven capable of reaching 350F • Cooling Rack • Knife • Spatula • Serving Plate Process (Transformational, Value-Creating Steps) 1. 2. 3. 4. 5. 6. 7. 8. PREHEAT: oven to 350F for glass or metal pans, 325F for dark or non-stick pans. GREASE: bottom of pan with shortening or cooking spray. MIX: empty brownie mix, eggs, oil and water in large bowl. STIR: until well-blended (about 50 strokes). SPREAD: in greased pan and bake immediately. BAKE: following times listed per pan size (ex: 8” X 8”: 42-45 Minutes. Add 35 minutes for dark or non-stick pans. DONE: when inserted toothpick 1” from edge of pan comes out clean. COOL: completely in pan before cutting and serving. Outputs (Requirements) • 2” X 2” Fudgy Brownie • Warm & Gooey • Served on 6” Serving Plate Customer • Annie Sweers KAIZEN BREAKTHROUGH METHOD 1. Pre-Event Planning 2. Event Execution Kaizen Sponsor Secured? Kaizen Team Trained, Ground Rules Established. Kaizen Team Leader assigned? Current State Condition Identified. Kaizen Target Area Selected/Scoped? Opportunities for Improvement Defined. Kaizen Dates & Times Scheduled? Future State Improvements Implemented & New Process Standardized. Kaizen Team Room Scheduled? Kaizen Team Members Assembled (Rule of 1/3’s, SIPOC) Kaizen Supplies Collected? Kaizen Pre-Work/Data Collected? 3. Post-Event Monitoring Catering Scheduled? Kaizen Training Material Prepared? Management Report-Out Scheduled? Visual Controls are in place, Maintained & Continuously Improved. Standard Work Audits are Conducted, Economic Benefits calculated & Results Communicated. Weekly Kaizen Newspaper Accountability Meetings Conducted. Management Report-Out Created & Delivered. Adhere to the Improved Process, Continue to Improve & Retrain After Each Improvement. KAIZEN BREAKTHROUGH METHOD: RESULTS Current State Process (7 Days) WASTE 7 Days V/C 56 Minutes Kaizen Value-Creating Work Waste WAITING 2 Days (2 Days) V/C 10 Mins Lean IT: Impact on Amway • • • • • • • Service Desk Data Center IT Asset Management Operations Voice Telecom Release management Application Development Service Desk • Corporate data stores Average of 100 requests per month Original process plagued with excessive active and wait times Active time reduced from 45 minutes to 15 minutes SME provides clear direction on users’ needs Process to be leveraged globally Service Desk • Granting Remote Access Focused on providing correct access without hand-offs Ensuring we meet PCI compliance requirements Decision tree developed and training provided for SD staff Standard work reduces training time • Returned capacity = 1,400* hours (Jan-Aug 2012) * Includes time savings in IT Security and Network Services What Have We Learned? • New concept to IT Lean is traditionally associated with manufacturing Many of the things we do have a production flow to them • Balance between focusing on results vs. learning • Staff hesitation to act without management direction Empowerment is critical Innovation, learn by doing • Quantified improvements vs. observed improvements What Have YOU Learned? QUESTIONS Tours • Service Desk • IT Operations • PC Lifecycle Lean Cell …Please gather in the lobby… David will be your guide