Summary 7-Measure

advertisement

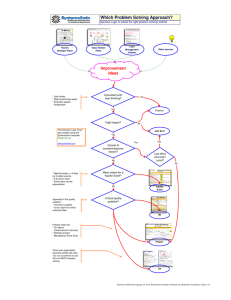

Measure Phase: Applying Objective Criteria to the Process As you move into the Measure Phase, you will be addressing the second and third blocks of the A3 that ask you to define the current situation and to establish realistic goals. This involves mapping the current process, selecting relevant aspects to measure, and identifying gaps between process performance and benchmarks. Map the process by developing a Current State Map. This looks like a flowchart, with the addition of a time component for each step in the process. A CSM uses just four basic shapes – oval, rectangle, diamond and triangle – plus arrows to describe the process. Ovals stake out the beginning and end of the process. Rectangles denote an activity. Diamonds indicate a decision point. Triangles show delay. Observe the process, consult with participants to ensure that you have captured all steps, and measure how much time is involved with each step. The time should be recorded below the appropriate symbol. The next step in the Measure Phase is to collect objective data on process performance. The team must consider which metrics are relevant – be they quality, cost, time, or output – and then work to isolate the “vital few” problems. The Lean rule of thumb is that 20% of the causes result in 80% of the problem. Decide how detailed your information needs to be and what tools to use. With this information, you can complete step two of the A3, Current Situation. Now revisit the benchmarks you initially established in the Define Phase. Do they cover all of the key performance indicators? If not, gather additional benchmark information. Now you can identify where the greatest opportunity for improvement exists. As you formulate your answer for step three of the A3, Target Goal, remember that Lean is meant to be an iterative process. Avoid trying to do too much. Not only might it be infeasible (and a recipe for failure), but it could result in an overcorrection and lead you in a different, but still undesired, direction. Lean experts suggest aiming for 60% of your ideal, improve, verify your accomplishment and ultimate goal, course correct as necessary, and improve again. 1