3.Presentation On Improvements In Operational

advertisement

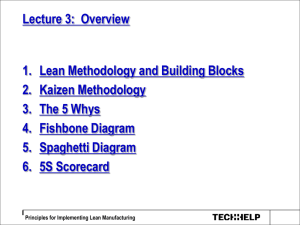

JIT Stock Control • No buffer stocks , components arrive when needed • Supplier relationships have to be excellent • Production staff must be multi-skilled and ready to change jobs • Equipment must be flexible • Demand forecasts must be accurate • Latest IT equipment required • Good employer-employee relationships • Quality = Priority. Advantages • • • • • Less capital , lower op cost Lower costs Less chances of stock becoming obsolete Staff motivation Quicker response time through systems Disadvantages • Supply failure = System Breakdown • Higher delivery costs ( small deliveries ) • Order admin costs • Lower bulk discounts • Reliance on outsiders . Lean Production • Lean manufacturing or lean production, is the optimal way of producing goods through the removal of waste and implementing flow, as opposed to batch and queue . • Quality output with fewer resources . Simultaneous Engineering • R&D done simultaneously for new products. • New products arrive faster eliminating the danger of obsolesce • Unlike sequential engineering . Flexible Specialisms • Technology + Changing consumer tastes make very short production runs • Quick changes require : • Flexible Work Contracts • Flexible machinery • Flexible Workers • This leads to quicker response times , wider ranges , reduced stock holdings and increases in productivity . • This is also called time based management . Kaizen Kaizen • Continuous Improvement • All workers contribute • Managers DO NOT know best in all cases • Small makes big • Management culture promotes worker involvement • Quality cells that are empowered • All staff are involved Evaluating Kaizen • Its limitations include : • Senior mangers may resist • Short term tangible costs • Important advances made only early on • Some proposed changes may require a complete overhaul and so may be expensive