Quality Control

advertisement

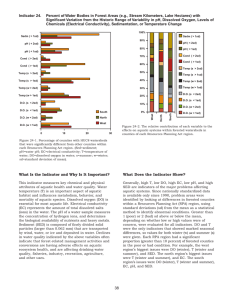

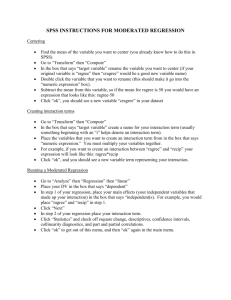

ISSUES OF CLINICAL LABORATORY QUALITY ASSURANCE PROGRAMME IN PAKISTAN Brig (R) Dilshad Ahmed Khan SI (M) Professor of Pathology NUMS, Rawalpindi Quality Assurance Programme Quality Control - The aim of quality control is simply to ensure that the results generated by the test are correct & verify that the testing system is working properly. Quality Assurance - Ensures that the final results reported by the laboratory to the patient are correct: that the right test is carried out on the right specimen, right interpretation/result is delivered to the right person at right time Factors That Affect Quality of Patient’s Results The condition of the specimens Reagents & Equipment Internal quality controls program Participation in external quality program The interpretation & reporting of results Unreliable QA Program ? Potential consequences of unreliable QA Performance include: Patient misdiagnosis Delays in treatment Increased costs QA Performance Failure Pre-analytical:- – Errors before the sample reaches the laboratory Analytical:- – Errors during the analysis of the sample Post-analytical:- – Errors occurring after the analysis Pre – Analytical Issues Sample Collection Sample haemolysis/ Incorrect specimen container Sample Transport Delay in samples delivery/ Temperature Incorrect specimen storage Sample left overnight at room temp/ long term storage at 4c Improper Collection of Blood Samples Sample haemolysis LDH, potassium or inorganic phosphate Effects of exercise creatine kinase / CRP Collection timing 24 hour urine Incorrect Specimen Container – Serum or plasma • PTH, ACTH – Fluoride tubes for glucose • to inhibit glycolysis – EDTA tube • Unsuitable for calcium assay Incorrect Specimen Storage – Sample left overnight at room temperature • Falsely elevated K, Pi and red cell enzymes • short –term refrigeration • medium term freezing at –20oC • long term freezing at -80oC – Delay in sample delivery • Falsely lowered levels of unstable analytes Internal Quality Control Daily running of two control sera Calculation of their mean and standard deviation Plotting them on control charts Daily checking and Interpretation of graphs Example Mean result (x) = 100 mmol/L Standard deviation (SD) = 1.0 mmol/L Number of results (n) = 100 Mean +/- 1SD Frequency -1SD x +1SD 68% 99 100 101 Values fall randomly about a mean value. Mean +/- 2SD Frequency -2SD x +2SD 95% 98 100 102 Values fall randomly about a mean value. Accuracy ? How correct your result is. Precision ? The reproducibility of your results. Which is more Precise ? Performing better ? Potassium mean 5 ; SD = 0.1 mmol/L Sodium mean 140; SD = 2.0 mmol/L Example Potassium %CV = (0.1 / 5.0) x 100% Sodium %CV = (2.0 / 140) x 100% = 2.0% = 1.4% Sodium has the better CV and in this example is performing better than potassium. Westgard Rules Westgard provides multiple QC rules: Defines acceptability of analytical process minimises false rejections maintains high error detection Westgard Rules 19 Levey Jennings Chart +2SD 143 +1SD 141.5 X X X X Mean X X X X X X X 140 X X X -1SD X -2SD X X 138.5 137 Levey Jennings Chart +2SD 143 X X X +1SD 141.5 X X X Mean X X X X X X 140 X -1SD X -2SD X X X 138.5 137 Levey Jennings Chart +2SD 143 +1SD X X X X Mean X X X X X X X X X 141.5 X X 140 X X -1SD 138.5 -2SD 137 Levey Jennings Chart 143 +2SD X X +1SD X X X Mean X X X X X X X X X X 141.5 X X 140 -1SD 138.5 -2SD 137 Shift ? Inaccurate calibration/recalibration Sudden failure or change in the light source Change in reagent formulation Change of reagent lot Sudden change in incubation temperature (enzymes ) Failure in the sampling system Failure in reagent dispense system Levey Jennings Chart? X +2SD 143 X X X X +1SD 141.5 X X Mean 140 X X -1SD X X 138.5 X X -2SD X X X X 137 Trend ? Gradual deterioration of control materials Deterioration of the instrument light source Gradual accumulation of debris in sample/reagent tubing Aging of reagents Gradual deterioration of incubation chamber Gradual deterioration of light filter integrity Root cause analysis External Quality Assurance? Proficiency testing is the system designed to objectively assess the quality of results obtained by laboratories, by means of an external agency. Benefits of EQA Provide an inter-laboratory comparison Allows participants to identify problems with their testing process (Accuracy) Investigate factors in performance of tests (methods, Instrument, Reagents etc) Supplement internal quality control procedures Identifies improvement opportunities External QA Programme International Regional National International External QC REQAS (Rs 75,000/year) BIORAD (Rs 80000/year) CAP (Rs 100000/year) National External Quality Assurance Programme in Pakistan E Q A pre-requisite for any country Designed specifically for the country’s needs Economical Useful in establishing national quality goals Fulfilling the requirement of accreditation by PNAC (NEQAPP Rs 2000/year) NEQAPP Clinical chemistry PT programme Started in 1996 60 labs invited for the scheme 47 labs enrolled Each lab allotted a confidential code number QC sera sent every three months Results List of Analytes Albumin Bilirubin Cholesterol Creatinine Glucose Lithium Magnesium Osmolality Inorganic phosphate Potassium Total protein Sodium Triglycerides Urea Uric acid Acid Phosph. (Total) ALT AST Alkaline phosphatase Amylase CK LDH Cumulative statistics: Percentage bias Glucose Inorganic PO4 EQA: Causes of Poor Performance Methodological/reagents reasons (33%) Technical/intruments reasons (19%) Clerical reasons (12%) Blunders (11%) Un-explained reasons (25%) Expand Scope of NEQAPP Expand NEQAPP to all disciplines of Pathology Funding for necessary infrastructure Enhance QA of labs on national level PC-1 for NEQAPP Submitted in early 2005 Prepared By: Checked By: Brig Dilshad Ahmad Khan Brig Farooq Ahmad Khan Approved by: Maj Gen Masood Anwar, HI(M) PC-1 for NEQAPP Team of PNAC visited AFIP PNAC requested Surg Gen for cooperation Sectoral committee of PNAC for clinical labs PC-1 for NEQAPP was approved in 2009 Expand NEQAPP Programme offered in 2010 Clinical Chemistry Immunoassay/ Tumour Marker Haematology Microbiology Histopathology 160 No. of participating Labs No. of participating Labs 140 120 100 80 60 120 40 20 88 96 2010 2011 130 137 145 2013 2014 2015 47 0 1996 2012 New Participants 1 Questionnaire 2. Preparation of Panels 3. Panel Distribution 4. Data Collection 5. Data Analysis 6. Final Report Enrollment Documentation ENROLMENT DOCUMENT: - To be returned to NEQAPP, AFIP Rawalpindi With Following Information: LAB NAME E-MAIL PATHOLOGIST TELEPHONE NO ADRESS PROGRAMME When the details have been entered in the enrolment document it should be sent to NEQAPP, AFIP or Register on website for registration (www. Neqapp.net) Pre-requisites- NEQAPP List of analytes Methods Instruments/equipments Reagents Clinical Chemistry Immunoassay Instrument Code Reagent Suppliers Source PT Samples Lyophilized human serum Similar to patient specimens Appropriate concentration levels Good long term stability Easy to transport Reconstitution errors General Chemistry Program : Specimen Design High Pool Specify lowest and highest specifications 4 Level 6 3 + Low Pool 2 1 Low Pool Level 1 Lyophilized human serum High Pool General Cycle of an EQA Laboratory monitors or takes corrective action Initial documentation Laboratory analyzes samples and sends results to EQAS PT provider sends report to laboratory Input and validation of data results Report generated showing individual laboratory & all data Statistical data processing Return of Results Reconstituted samples on or before the recommended date for analysis and forward your results on the return sheets provided to arrive at NEQAPP Coordinator by the FINAL DATE. Results will normally be processed within 10 days of the FINAL DATE. Reports usually take 2 weeks to print and dispatch Late Results Results received after the FINAL DATE will be processed retrospectively. NEQAPP Results Date CLINICAL CHEMISTRY & IMMUNOASSAYS Scheme Mar Jun Sep Dec General Chemistry X X X X Endocrinology X X X X Tumour Marker X X X X Reports Identity of participants is usually kept confidential Your lab analytes mean are compared with group mean Allowable Limits of Performance (SDI) Show statistical data and summaries Pass/Fail Cat 1-Labs with all analytes passed Cat 2-Labs with >80% analytes passed Cat 3-Labs with <80% Analytes Passed Clinical Chemistry Immunoassay n=35 Reports provide Data of your lab performance as well as comparison with other laboratories Analytes that have performed poorly can be identified Report will assist in determining the cause and corrective action Conclusions Efforts are required to education about QA. More labs should participate in the to improve the quality of patients results. Need for realization of NEQAPP problem. Official backing/sponsors are required.