Key elements we would like to tackle: → Functional silos, the need

advertisement

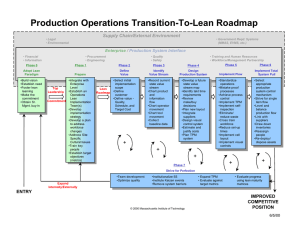

Key elements we would like to tackle: → Functional silos, the need to engage the organisation in co-developing their future, change management and behaviour, in particular leadership behaviour. → None of these topics are new. We have had a lot of discussions about what needs to be different. We’d like to get practical on how you can make the change happen in reality, and what this could mean to you. 1 → We help senior clients understand where they are in their journey, where they want to go and at the same time showing them what THEY need to do differently. → Starting on the left, doing a bit of 5S or Kaizen. The job of leadership here tends to focus on creating awareness → Moving on, we go to where many companies are today, they have a Lean system, so still fairly technically focused, usally originating in manufacturing or a heavily transactional, volume driven environment. It will be standardised, their will probably be an audit or assessment approach to see what parts of the system have been implemented and how much. Here we see leadership ’sponsoring’ implementation and driving compliance to these new standards. That is exactly what is needed to get the system implemented but that only gets you so far. → Now we want to move from function to end to end, value stream improvements. To do that we need to embed real Lean thinking, the essence of Lean, not just how to use the tools. Leaders need to live Lean, not sponsor Lean. It should be THE WAY you meet you business targets. And the role of the Leader, to reinforce Lean behaviour, collaboration, experimentation. This step is challenging AND ONLY WORKS if leadership are committed. → As you go further, including all functions as well as your customers and suppliers, it is fully integrated into your organisations process, it is in your DNA, it is simply the way you work. → Our objective is to get over the wall, break the silos and move leaders from sponsor 2 → One thing we tend to find is that the Lean or Operating Systems are often expanding or becoming more complex to meet the differing needs of different functions. They have organically grown and contain everything you could possibly need. → To make it simple, and digestable for leadership, consider fundamental principles. Often people try and implement too many things rather than the critical few, in the right order, that really delivers results. Often missing the basics in performance management. → You should be able to match your requirements in business performance (KPIs) to what you can implement, in what order to improve performance. 3 → Behaviours / leadership programs often disconnected from practical activity. → Instead of diving into leadership behaviours from the text book we engaged the teams and worked on the ’experience’ we want to create. → Make a joint commitment, and measure it / discuss it every week, as a team. → To implement behavior, you need to observe it, you need to coach it, on the job – situational coaching. 4 → The challenge is consistency, a fall back in behaviour for a couple of weeks can put the transformation back for months. 5 → Genba (in japanese) is ’the real place’ or ’the crime scene’ → Breaking down silos, you can structurally force collaboration – forecasting and planning across the value stream – the CUSTOMER does not care about functional performance, what is the performance of the value stream? Change in the operating model, you can start by changing the way we see and manage performance. → We often see challenges with companies driving single point accountability, however this doesn’t work passed one of 2 levels of exec leadership, the matrix is real. The key is to build shared objectives with clear individual accountabilities. → Nobody can deny this is a great ambition, but the leaders in your business simply may not know how. This is where the change/transformation teams come into play, where you come into play. 6 → Helping people link the system to delivering their business results – locking it in to ’the way we run the business’ → Emotional intelligence, going beyond the transaction / the project – thinking about how the individual is feeling → Understanding some of the basics of psychology ‐ positive and negative reinforcement. → Change management – going beyond training and communication → Leadership, biggest challenge – manage at the surface then deep dive. Personal effectiveness, diary management, priorities – delegation, getting the best out of your people, motivation. 7 Context → Big ambition, volumes, new models, global expansion, bring quality up to best‐in‐ class and more predictable meet their year on year productivity targets → Organisation survey higlight challenges, ford era, down sizing, leaders stepping down into day to day decisions → Company philosphy designed around the operator, the individual – openeness to learn together and embark on an exciting change. → It took 3 months to bring forward a picture for the leadership to create this change in thinking. And 8 months to build understanding and co‐design the system with them. One month to ’pilot’. 2 years to implement in manufacturing alone. → This is now the flah ship for the entire organisation, similar journies in R&D, etc. → It delivered! 8 → Create time: start with a blank page, 2 days to design, 8 weeks to build courage, implemented overnight → Take your time with the senior teams, building knowedge, don’t allow them to have an excuse to sit on the outside looking in. → Results, results, results – this is how you really get credibility → Keep things simple. Real focus on people, focus on excellence and training, not exessive supervision. 9 → Putting in place the pre‐requisites → Building understanding → Mapping and understanding the value stream in your area → The topics are not new, but from an application perspective what is new is the shift in the way we support clients to drive performance improvements. 10 → Coaches, respect people from the business and the existing more technical teams. They need to know the context of the individuals they were coaching. → Pulling out one of the most seasoned factory managers out of the role for 2 years to lead the program as the ambasador for lean leadership. → Cascading down through an aligned exec leadership programme. → All focus on motiviating and enabling people to deliver breakthrough performance. 11 12 13 14 15