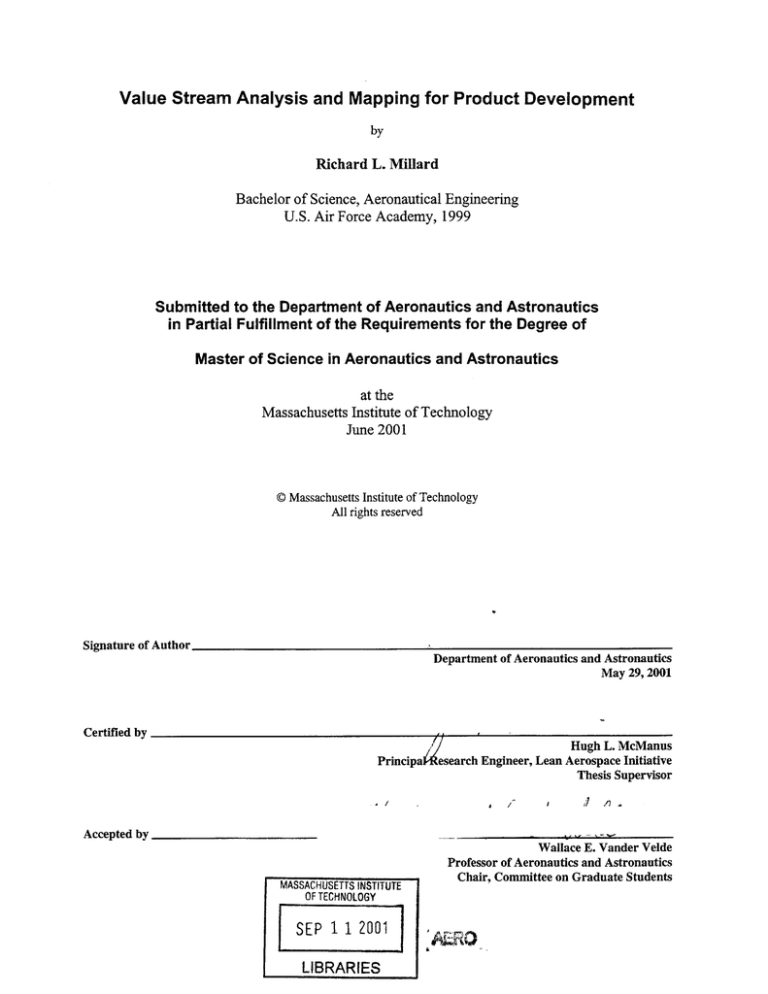

Value Stream Analysis and Mapping for Product...

advertisement