Sodium sulfite grades

advertisement

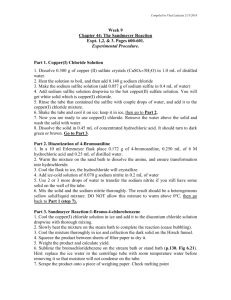

Technical Leaflet Sodium sulfite grades M 5873 e July 1999 (rws) Supersedes issue dated June 1995 ® = Registered trademark of BASF Aktiengesellschaft Sodium sulfite anhydrous A Sodium sulfite anhydrous PHOTO GRADE Sodium sulfite anhydrous FOOD GRADE Reducing, bleaching and sulfiting agent, auxiliary for many branches of industry Chemicals Sodium sulfite types Chemical name Sodium sulfite Commercial names Sodium sulfite anhydrous A Sodium sulfite anhydrous PHOTO GRADE Sodium sulfite anhydrous FOOD GRADE (E No. 221) Chemical formula Na 2SO 3 Molar mass 126.04 g CAS No. 7757-83-7 EINECS No. 231-821-4 Forms and packs supplied The products sodium sulfite anhydrous A, PHOTO GRADE and FOOD GRADE can be purchased in 50 kg and 25 kg sacks. The product can also be delivered in big bags and road or rail tankers. Disposable pallets are used, and wrapping is possible at the customer’s request. Properties Sodium sulfite is a white or pale yellowish, odorless microcrystalline powder. The apparent density is 1400 –1600 kg/m 3. Sodium sulfite slowly absorbs water on storage in closed containers. This is associated with oxidation to form sodium sulfate. In open containers, this process is greatly speeded up. The absorption of water is accompanied by formation of more or less hard agglomerates. Sodium sulfite is readily soluble in water. The solutions show an alkaline reaction. Exposure to air results in rapid formation of sodium sulfate. Table 1 Density and composition of sodium sulfite solutions of various concentrations Na 2SO 3 concentration Na 2SO 3 content g/100 g g/100 ml Amount of Na 2SO 3 required for preparation g/100 ml Density g/100 ml 5 5.23 5.39 104.6 10 10.97 11.31 109.7 15 17.22 17.75 114.8 20 24.06 24.8 120.3 2 Temperature °C 100 80 60 40 20 0 –20 0 5 10 15 20 25 30 Concentration in g/100 g Figure 1 Solubility of sodium sulfite in water Product specifications The values and test methods stated in the product specifications below are those applying when the technical data sheet was drawn up. Because changes are possible, those interested are requested to ask for the product specifications currently applying. The only values which are binding are those in the relevant specification sheets then provided. Sodium sulfite anhydrous A Unit Typical value Limit Test method Na 2SO 3 g/100 g 98.2 min. 97.5 ISO 418-1994 (E) SO 2 g/100 g 49.9 min. 49.5 calculated 9.2 8.5 –10.5 RCA/Q-S-066 < 20 max. 50 RCA/Q IC-01 max. 10 AES BASF M91/41 max. 10 AAS BASF M90/5 remainder calculated pH value (50 g/l) NaCl mg/kg Heavy metals as Pb mg/kg Iron mg/kg Na 2SO 4 g/100 g <5 Product specification RCA_NSA_E of Feb. 10, 1999, Rev.: 2 3 Sodium sulfite anhydrous PHOTO GRADE Unit Typical value Limit Test method Na 2SO 3 g/100 g 99.0 min. 98.3 ISO 418-1994 (E) SO 2 g/100 g 50.3 min. 49.9 calculated Insoluble matter g/100 g < 0.1 max. 0.5 ISO 10349-3 pH value (50 g/l) – 9.3 9.0 –10.0 RCA/Q-S-066 Alkalinity (as Na 2CO 3) g/100 g – max. 0.15 ISO 10349-7 NaCl mg/kg < 10 max. 20 RCA/Q-IC-01 AgNO 3 test – – fulfilled ISO 10349-9 Fe mg/kg <5 max. 5 AAS BASF M90/5 Heavy metals as Pb mg/kg – max. 10 AES BASF M91/41 Appearance of solution – – fulfilled ISO 418-1994 (E) Na 2S 2O 3 g/100 g – max. 0.015 ISO 418-1994 (E) Na 2SO 4 g/100 g – remainder calculated Product specification RCA_NSPG_E of Feb. 10, 1999, Rev.: 2 Sodium sulfite anhydrous FOOD GRADE Unit Typical value Limit Test method Na 2SO 3 g/100 g 98.5 min. 98.0 ISO 418-1994 (E) SO 2 g/100 g 50.0 min. 49.8 calculated 9.2 8.5 –10.5 RCA/Q-S-066 pH value (10 % solution) Heavy metals as Pb mg/kg – max. 10 AES BASF M91/41 Fe mg/kg <5 max. 10 AAS BASF M90/5 As mg/kg – < 0.1 AAS BASF M90/7 Pb mg/kg – < 0.1 AAS BASF M90/5 Cu mg/kg – < 0.1 AAS BASF M90/5 Hg mg/kg – < 0.03 AAS (cold vapor) Se mg/kg – < 0.1 AAS BASF M90/8 Zn mg/kg – < 0.1 AAS BASF M90/5 Na 2S 2O 3 g/100 g – max. 0.02 ISO 418-1994 (E) Na 2SO 4 g/100 g – remainder calculated Product specification RCA_NSFG_E of Feb. 10, 1999, Rev.: 2 Sodium sulfite anhydrous FOOD GRADE is subject to provisional approval in the EU according to EC directive 96/77/EC (of Dec. 2, 1996) annex III part B (E No.: 221), in the foodstuffs listed therein and in the stated maximum amounts, as preservative and antioxidant. The product also complies with the requirements listed for sodium sulfite in the Food Chemical Codex, 4th edition (FCC IV) on page 383. These requirements are the criterion for use in the foods sector for North America, parts of South America and for many countries outside the EU. 4 Finally, this product also meets the requirements listed in the compendium of food additives specifications of the FAO/WHO Joint Expert Committee on Food Additives (JECFA), Rome 1992, page 1395. Chemical properties Sodium sulfite has reducing, bleaching, sulfiting and preservative effects. Acidification results in evolution of the pungent and toxic gas sulfur dioxide. Sulfur dissolves in aqueous solutions of sodium sulfite to produce sodium thiosulfate. Applications In the chemical and chemical engineering industries: – for producing sodium thiosulfate, – as reducing agent, for sulfonation and sulfomethylation. In the manufactured fiber industry: – for solubilizing the raw materials, as addition to coagulant baths, for bleaching, for removing sulfur from the yarn. In the textile industry: – as antichlor after treatment with chlorine or with compounds which contain active chlorine. In the leather industry: – for sulfiting tanning extracts. In the explosives industry: – in the production of trinitrotoluene. In the rubber industry: – for stabilizing latex. In the photographic industry: – to protect developer solutions from oxidation. In the food industry: – as preservative and bleach (restricted use in accordance with the additive approval regulations E 221). In the paper and pulp industry: – quality-improving effect in the CTMP and TMP processes for producing semichemical pulp and pulp, in the processing of rags and in the cooking of straw. Auxiliary in the treatment of water (prevention of corrosion due to depletion of oxygen, and for removing chlorine from industrial water). For waste water treatment in the electroplating industry. For removing oxygen from boiler feed water (as long as the steam temperature is below 300°C and the sodium sulfate which is formed can be removed by blow-down). 5 Safety Biological effects Sodium sulfite is an odorless powder. It is not generally irritating for the skin; however, sensitive people prone to allergies may on prolonged exposure experience reddening of the skin. Lengthy contact with the skin, and inhalation of the fine dust must be avoided. Contact with acids may lead to evolution of toxic sulfur dioxide gas. In water courses, sodium sulfite leads to extensive oxygen depletion, which may have adverse effects on organisms. However, if properly introduced into adapted biological treatment plants, no impairment of the degradation activity is to be expected. Safety advice According to the data available to us, sodium sulfite is not included as a hazardous substance in annex 1 of EC directive 67/548/EEC. Storage and transport All sodium sulfite types should be stored under cool and dry conditions. They are stable for 6 months if the storage temperature does not exceed 25 °C and the relative humidity does not exceed 45 %. If higher temperatures and/or higher humidities occur during storage, this may lead to a decrease in the SO 2 content and the pH of the aqueous solution. Similar effects are produced by wide variations in the storage temperature. The chemical changes may be accompanied by the formation of more or less hard agglomerates. Hard agglomerates are also caused by increased pressure – for example if pallets are stacked on top of one another. Safety data sheet Further information on the sodium sulfite types is to be found in the relevant safety data sheets. Note The information submitted in this publication is based on our current knowledge and experience. In view of the many factors that may affect processing and application, these data do not relieve processors of the responsibility of carrying out their own tests and experiments; neither do they imply any legally binding assurance of certain properties or of suitability for a specific purpose. It is the responsibility of those to whom we supply our products to ensure that any proprietary rights and existing laws and legislation are observed. 6 Printed in Germany BASF Aktiengesellschaft Marketing Petrochemikalien und Anorganika 67056 Ludwigshafen, Germany