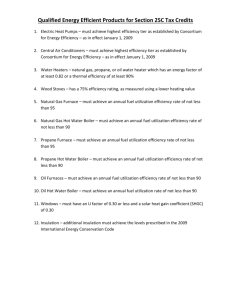

Nos. 2/3 Power Station Decommissioned Equipment No. 2 Power

Nos. 2/3 Power Station

Decommissioned Equipment

No. 2 Power Station

21-25 Steam Turbine Generators

All are in poor condition and some partially disassembly.

26GTG:

GE Frame 5

18.8MW @ .80pf, 13.8KV

600psig to 150psig steam helper turbine

GT engine always operated on natural gas

Generator rotating field - recently rewound

Commissioned ~ 1966

Decommissioned in May 2012

Approximately just over 300,000 operating hours.

Last Major OH in late 2004/early 2005.

Rewound the rotating field in 2006.

Did last Hot Gas Path Inspection and work in 2008.

Machine was running well when we shut down

27STG:

GE Condensing Steam Turbo generator

21.800MW, 13.8KV

600psig throttle, 150psig extraction, 130, 000#/hr condensing

Commissioned ~ early 1980’s

Decommissioned ~ 2005 (?)

Nos. 21 – 28 Boilers

B&W Dual Fuel Fired 600psig @720degF

225,000pph

Drum type combustion air pre heater

Commissioned pre WWII thru 1950’s

Decommissioned (various)

All are in very poor condition

No. 29boiler

Combustion Engineering 600psig @ 720 degF

400,000 pph

Dual fuel fired in addition to GTG 26 exhaust

Commissioned ~ 1966

Decommissioned in 2012 – OK condition

Joy Air Compressor

TA30 w/turbine driver

110psig at 3,000 ICFM

Commissioned (unknown)

Decommissioned May 2012

Boiler Feedwater Pumps

4ea. various manufactures

807psig discharge pressure @ 1100GPM

Driver horsepower ~700hp (electric motor)

1ea dual drive, 150paig-15psig turbine-turbine not coupled

All of these pumps are in good operating condition.

Heat Exchangers

2ea Boiler Blowdown/Feedwater (Decommissioned in the 80’s)

2ea. in the fuel oil area

EXCH. # 25 ( 29 BOILER EXCH.) SOUT EAST CORNER OF BOILER ROOM.

Tubes – 316 ss 16 Gauge, Shell Steel w/304overlay

EXCH. # 35 ( SWEETWATER COND. ) SOURH WEST END OF BOILER ROOM.

Shell – SA-516-70, Tubes A-214, Total Weight = 24,300lbs.

EXCH. # 23 ( ON ROOF OF BOILER ROOM.

Shell – Steel, tubes 14BWG Copper , Total Weight – 27,000lbs.

# 2 H.P.H. ON ROOF OF BOILER ROON. AND #1 HPH ONROOM OF BOILER ROOM. ( NO #,S ON

1&2 EXCH.,S)

Shell – Steel, tubes 14BWG Copper, Total Weight – 25,000lbs ea.

EXCH.# 29 ( SOUTH SIDE OF BOILER ROOM ) AND THREE OTHER,S WITH NO #,S ON THEM.

No. 19,25,28 and 29 – Shell Steel w/304 clad, Tubes – 16BWG red brass (7030 CU NI)

FUEL OIL AREA EXCH. SER.# W-2134-1B ( ITEM- # E-2)—AND EXCH. SER.# W-2134-1A ITEM# E- 1

Data Not Available

Instrumentation

29Blr Analyzer Building complete with all equipment

No. 27 STG Transformer

13.8KV to 34.5KV Generator Step Up Transformer

Aprox. 25MVA

Commissioned ~ 1982

De-commissioned in ~2005

No. 26 GTG Transformer

13.8KV to 34.5KV Step Up Transformer

Aprox. 20MVA

Commissioned ~1966

De-Commissioned May 2012 – good condition

No 29 Cooling Tower

5 Cell Cooling Tower with pumping equipment

No3 Power Station

No. 31 Boiler

Riley Stoker Dual Fired 900psig @ 725F

330,000 opph

Drum combustion air preheater

High pressure BFW heater

Commissioned ~1956

Decommissioned~2003

OK Condition

No. 32/33 Boiler

Ditto 31 except decommissioned May 2012

Excellent condition with new control valves and field instrumentation in 2009.

Fuel Oil System

Last contained No2 Fuel Oil

System consists of a fuel oil tank, 2 fuel oil pumps, piping and regulator valves.