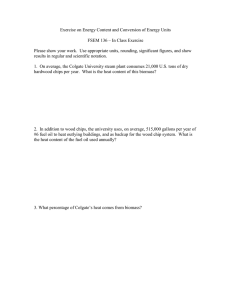

Queen Margaret University: Biomass Wood Chip Heating

advertisement

CASE STUDY – BIOMASS Steve Scott, Director of Campus & Commercial Services, Queen Margaret University www.qmu.ac.uk “We have had a biomass energy centre feeding our campus for five years. There were difficulties early on, but never really any technical problems. It's a straightforward combustion process but there was a perception issue about the technology; we came in very early and at the time, had the largest non-industrial biomass boiler in the UK. We suffered from being one of the pioneers and had to work hard. There were not a lot of experts or reports to draw upon and we had to look to Europe for our boiler technology because there was not much in the UK then. There were issues around fuel supply because we were getting grants from the UK and they didn't necessarily understand that Scotland has a plentiful supply of trees and that transportation costs were insignificant. We went down the wood chip rather than the pellets route - bark, thinnings and waste material from the forestry process. A lot of people use pellets, which have a manufacturing cost. We secured long-term energy supply agreements (with Bucchleuch BioEnergy) and have had no problems with fuel supply. Fuel choice is key - match the fuel to your load. We have a fairly constant demand because of different activities and that suits the kind of fuel we have got. It has worked very well, providing heating and hot water to all buildings, including academic buildings, the students' union and 800 residential units. We had to put in additional capital investment but while we were looking at a 7-8 year payback, it has paid back in 6 years. My main advice would be to take care with your design. We were lucky - we had a field and could design our physical installation to be as efficient and effective as possible. Retrofit is more challenging and you need to consider the viability. Also, engage early with a contractor with relevant expertise – we really benefited from that.”