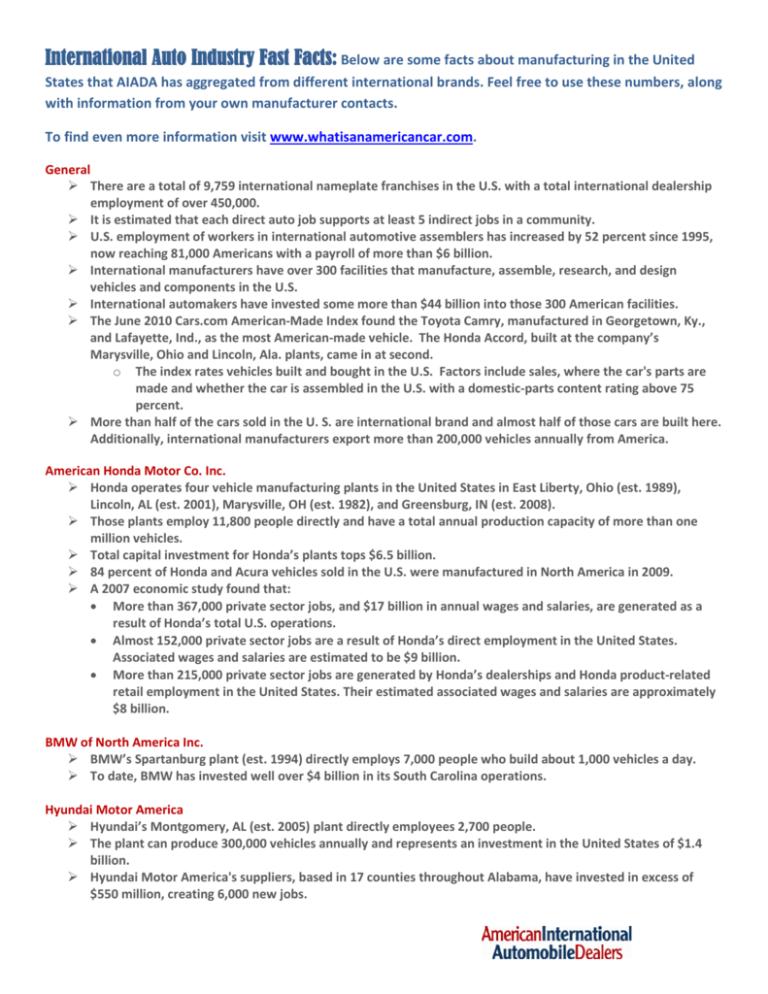

International Auto Industry Fast Facts: Below are some facts about

advertisement

International Auto Industry Fast Facts: Below are some facts about manufacturing in the United States that AIADA has aggregated from different international brands. Feel free to use these numbers, along with information from your own manufacturer contacts. To find even more information visit www.whatisanamericancar.com. General There are a total of 9,759 international nameplate franchises in the U.S. with a total international dealership employment of over 450,000. It is estimated that each direct auto job supports at least 5 indirect jobs in a community. U.S. employment of workers in international automotive assemblers has increased by 52 percent since 1995, now reaching 81,000 Americans with a payroll of more than $6 billion. International manufacturers have over 300 facilities that manufacture, assemble, research, and design vehicles and components in the U.S. International automakers have invested some more than $44 billion into those 300 American facilities. The June 2010 Cars.com American-Made Index found the Toyota Camry, manufactured in Georgetown, Ky., and Lafayette, Ind., as the most American-made vehicle. The Honda Accord, built at the company’s Marysville, Ohio and Lincoln, Ala. plants, came in at second. o The index rates vehicles built and bought in the U.S. Factors include sales, where the car's parts are made and whether the car is assembled in the U.S. with a domestic-parts content rating above 75 percent. More than half of the cars sold in the U. S. are international brand and almost half of those cars are built here. Additionally, international manufacturers export more than 200,000 vehicles annually from America. American Honda Motor Co. Inc. Honda operates four vehicle manufacturing plants in the United States in East Liberty, Ohio (est. 1989), Lincoln, AL (est. 2001), Marysville, OH (est. 1982), and Greensburg, IN (est. 2008). Those plants employ 11,800 people directly and have a total annual production capacity of more than one million vehicles. Total capital investment for Honda’s plants tops $6.5 billion. 84 percent of Honda and Acura vehicles sold in the U.S. were manufactured in North America in 2009. A 2007 economic study found that: • More than 367,000 private sector jobs, and $17 billion in annual wages and salaries, are generated as a result of Honda’s total U.S. operations. • Almost 152,000 private sector jobs are a result of Honda’s direct employment in the United States. Associated wages and salaries are estimated to be $9 billion. • More than 215,000 private sector jobs are generated by Honda’s dealerships and Honda product-related retail employment in the United States. Their estimated associated wages and salaries are approximately $8 billion. BMW of North America Inc. BMW’s Spartanburg plant (est. 1994) directly employs 7,000 people who build about 1,000 vehicles a day. To date, BMW has invested well over $4 billion in its South Carolina operations. Hyundai Motor America Hyundai’s Montgomery, AL (est. 2005) plant directly employees 2,700 people. The plant can produce 300,000 vehicles annually and represents an investment in the United States of $1.4 billion. Hyundai Motor America's suppliers, based in 17 counties throughout Alabama, have invested in excess of $550 million, creating 6,000 new jobs. Kia Motors America Inc. Kia’s West Point, GA facility (est. 2009) employs 2,500 directly building 300,000 vehicles annually. Kia has invested $1 billion in their Georgia plant, and helped revive a struggling community. Mazda Motor of America Inc. Mazda has a plant in Flat Rock, MI (est. 1987) and a joint venture with Ford in Kansas City, MO (est. 2000). Total U.S. annual production for Mazda is more than 40,000 vehicles built by 7,800 employees. Mercedes-Benz USA Three thousand employees build 300,000 Mercedes a year in the MBUSI plant in Tuscaloosa County, AL. MBUSI alone is responsible for more than 10,000 direct and indirect jobs in the region, and has an annual economic impact of more than 1.5 billion. MBUSI is now Alabama’s largest exporter. Mitsubishi Motors NA, Inc. Mitsubishi’s Normal, IL plant (1988) directly employs more than 1,300 people and produces 135,000 vehicles a year. Mitsubishi acts as an economic catalyst in Illinois by contributing about $150 million annually to the local economy in taxes, salaries, and benefits. Nissan North America Inc. Nissan has two vehicle manufacturing plants in the U.S. in Canton, MS (est. 2003) and Smyrna, TN (est. 1983). Those plants employ a total of 10,000 workers capable of producing 950,000 vehicles annually. The plants also represent a $3.9 billion investment in the U.S. Today, over 800 automotive-related companies are located in 93 of Tennessee’s 95 counties. The industry employs over 159,000 people with a payroll of $6.6 billion. Subaru of America Inc. Subaru’s Lafayette, IN plant (est. 1989) produces 240,000 vehicles a year and employs 3,400 people directly. The Subaru of Indiana plant was the first auto assembly plant in the U.S. to achieve zero landfill status nothing from its manufacturing efforts goes into a landfill. Everything is reused and recycled. Toyota Motor Sales U.S.A. Inc. Toyota’s vehicle production in the U.S. is accomplished by plants in Georgetown, KY (est. 1988), Princeton, IN (est. 1999), San Antonio, TX (est. 2006), and Tupelo, MS (coming in 2011). Together, those plants directly employ nearly 15,000 Americans and represent capital investment of more than $10 billion. Toyota’s U.S. plants annually build 1,050,000 vehicles. One of them, the Toyota Camry, was named Cars.com’s most American-made car of the year in 2010. Toyota’s charitable giving in the U.S., since 1987, is $487 million. In 2008, Toyota purchased $29.9 billion in goods, parts, and components from nearly 500 U.S. suppliers located in 35 states Volkswagen Group of America, Inc. VW’s Chattanooga, Tenn. plant will produce 150,000 vehicles a year and employ 2,000 workers. So far, $686 million has been awarded in local and state contracts. The plant represents a $1 billion investment by VW in the United States.