Word Version

advertisement

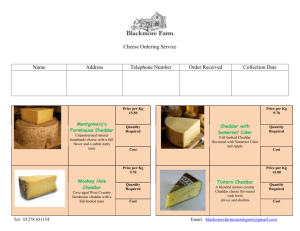

FSC 229 Practical Exercise #1 The Intercontinental Foods Company (IFC) operates an integrated multi-food processing complex (plant) on the west bank of the Mississippi River between New Orleans and Baton Rouge, Louisiana. About 60% of the food products are processed at the site. The remaining 40% are brought in partially processed. They are finished and packaged at this site. All food products are shipped from the plant by truck, rail car and ship. Ms. Jane Highstress is the General Manager at IFC who oversees procurement, processing, quality assurance, R & D (research and development) and marketing. At the October company meeting with Jane Highstress please be prepared to discuss the following: 1. Although batch processing operations provide versatility to a processing operations a continuous processing has numerous other advantages. For your presentation during the October meeting please discuss in detail the advantages of switching from a batch to a continuous processing operation for fluid milk or ice-cream processing. In your presentation outline the advantages and disadvantages of each process and explain how the advantages of a continuous process may outweigh these. 2. Inadequate heat processing of certain foods can have serious consequences resulting in illness sometimes death of those who consume the food, economic loss and possibly legal action against the processor. In your presentation in October please discuss the significance of adequate heat processing of foods to eliminate Clostridium Botolinum in canned green beans or Listeria Monocytogenes in meats. In your discussion include the significance of obtaining D and z values for these organisms. 3. Membrane separation technologies such as ultrafiltration, reverse osmosis, microfiltration have numerous advantages over traditional methods of processing. In your presentation in October please discuss why the company should invest in membrane separation technology to concentrate orange juice or remove alcohol from beer. In your discussion please provide comparisons to traditional methods in terms of product quality, time of processing, cost, labor etc. 4. Cheddar cheese is the most consumed cheese variety in the U.S. As U.S. consumer become more health concious there in an increasing demand for reduced- and low-fat cheeses. The food industry has responded promptly to this demand. As the supervisor dairy processing, at the October meeting please provide an overview of your reduced-fat Cheddar cheese manufacturing operation. The overview should start with the receiving of the raw milk at the plant and end with the packaging of the cheese at the plant. 5. Maintaining uniform quality of food products is extremely important to a food processor. As the supervisor of quality assurance department in the company at the October meeting please provide an overview of all the quality check points for the manufacturing of the Gold Brand (extra premium) ice-cream. In your discussion included all aspect of quality for ingredients and processing. 6. Enzymes which are proteins with catalytic properties are widely used in food processing and improvement of food quality. Enzymes play an important role both in the production of traditional and novel products. As an example enzymes are widely used by the starch and sugar processing industries and fruit juice industries. In your presentations during the October meeting please discuss how your department utilizes enzymes in the production of high-fructose corn syrup (HFCS) or for the clarification of juices. 7. Pasteurization is widely used in the food industry to destroy pathogens and extend shelf life food products. At the October meeting please provide an overview of the HTST pasteurization process providing some of the key features of a HTST pasteurizer. Discuss the pasteurization process for fluid milk or apple cider, including the legal aspects involved (during processing) into your discussion.