VOLUMETRICCTE - Precision Measurements and Instruments

advertisement

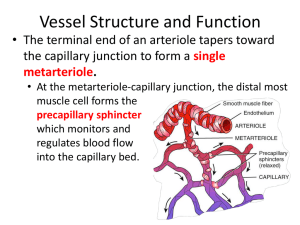

TECHNIQUE FOR VOLUMETRIC EXPANSION OF LIQUIDS

AND SOLIDS FROM 200-400K

_____________________________________________________________

Ernest G. Wolff

ABSTRACT

A new dilatometer for volumetric expansion measurements over the

temperature range 200-400K is described. It uses readily available fluids such as

ethylene glycol based mixtures and quartz capillaries with a demountable sample

container. Liquids and solids of any shape be measured. Equations permit a

complete parametric analysis for optimizing measurement resolution. It is shown

that results depend chiefly on knowledge of system dimensions and volumetric

CTE of the working fluid. A statistical F-test can be used to derive the volumetric

CTE of the sample for heating/cooling data. Measurements with variable sample

sizes of metallic test samples show excellent agreement with predictions, while

materials with higher volumetric CTE values would show proportional increases

in accuracy. Further studies with other working fluids, such as relatively pure

glycols, indicate further improvements in accuracy .

INTRODUCTION

Measurements of volumetric expansion, , have been of special interest to

studies of liquids, irregular material shapes, curing of adhesives, crystal and

particulate behavior. For an isotropic material, the linear thermal expansion

coefficient = (1/3) . For an orthotropic material = α1 + 2 + 3, so if two of

the linear coefficients are known the third can be deduced from a measure of the

volumetric expansion. Similar considerations apply to crystals with other types of

symmetry. Simple methods for accurate volumetric expansion measurements have

been sought for many years [1], but generally have had significant limitations,

such as temperature range, sample size and shape, leaking of liquid samples, or

had measurement problems in terms of reproducibility, accuracy, or ease of setup

[1,2]. Changes in density can in principle be used to derive volumetric CTE but

normal methods such as pycnometers [3,4], densitometers [5], hydrometers [6],

and gas volume changes [7] are limited by resolution and/or temperature ranges.

A method based on measuring the period of oscillation of a vibrating U-shaped

tube filled with liquid samples gave accuracy of 1 x 10-5 g/cc over the range 2535oC [8]. Dilatometers based on mercury require handling precautions [2,9], and

in any case mercury freezes below about 235K.

________________

Precision Measurements and Instruments Corporation, Corvallis OR 97333

1

The use of capillary tubes to follow a liquid expansion has been common [1012]. In cases involving direct liquid measurements, one method required sealing

of the quartz capillary and filling with the aid of a water jet [11] or centrifuge

[12]. Microscopes, telescopes and/or electronic calipers can be readily used to

measure the expansion of a liquid in a capillary.

THEORY

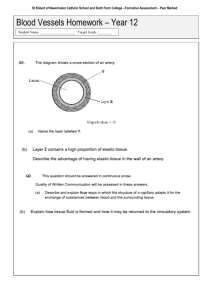

The present system is similar to that described in [2] but is simpler to

construct and use. Figure 1 illustrates the basic experimental scheme consisting of

a cylindrical cup containing the sample and covered by a lid with exiting capillary

tube. The working fluid fills the cup and a small section of the lower capillary

tube. Using symbols:

Vcap = volume of capillary from lid to height of fluid = hod2cap (/4)

Vfl = total volume of fluid (inside cup and capillary)

hc = initial height of cup

dc = initial internal diameter of cup

Vc = internal volume of cup = hc d2c (/4) for cylinder

hs = initial height of cylindrical sample

ds = initial diameter of cylindrical sample

Vs = sample volume, (hs d2s (/4) for cylindrical sample)

dcap = internal diameter of capillary tube

ho = initial height of (working) fluid in capillary

hfl = final height of (working) fluid in capillary

h = hf- ho

fl = volumetric expansion coefficient of fluid

s = volumetric expansion coefficient for sample

c = volumetric expansion coefficient of cup

fl = density of the fluid

If we consider a temperature change without any leaks, the total mass (*V) of

the fluid remains constant. From Fig 1 this implies;

ofl [ Voc – Vos + Vocap ] = ´fl [ V´c – V´s + V´cap]

(1)

where the o-superscripts denote initial values and the primes denote the values

after heating or cooling. Since, at constant pressure,

´fl = M [Vo (1 + V/V) ]-1

and V/V = fl (T) T

(2)

[Vc – Vs + ho d2cap (/4) ] ( 1 + fl (T) T) =

Vc(1 + c (T) T) – Vs ( 1 + s (T) T) + hf d2cap (/4)

(3)

2

A small amount of fluid resides in the quartz capillary outside the heated/cooled

zone at all times and does not participate in the temperature changes. βfl, βc, and βs

are normally functions of temperature. For example, while the expansion of a

quartz cup may be taken as zero, an aluminum cup is desirable for better heat

transfer and to minimize changes in Δh. Use of an aluminum cup suggests the

polynomial :

Βc (T) = βAl (T) = 3{ Bo + B1 T + B2 T2) }/ (T – Tref)

(4)

where the coefficients B0 = -0.583 x 10-3, B1 = 23.107 x 10-6 and B2 = 8.024 x

10-9, Tref = 25 oC and T is measured in oC. [13]. The sample and cup volumetric

expansions may often be considered constant over small temperature ranges, or

averaged over the test range. Then, the predicted change in fluid level in the

capillary is calculated from Equation 3:

(T – Tref) [ Vc fl (T) – Vs fl (T) + Vs s – Vc c + ho d2cap(π/4)fl (T) ]

h (T) = ---------------------------------------------------------------------------------(/4) d2cap

(5)

When the fluid alone is being measured, dcap, ho and βc can be assumed to remain

constant:

fl (T)

=

Vcc + (Δh(T) / (T – Tref )) d2cap (/4)

-----------------------------------------------Vc + ho d2cap ( /4)

(6)

We can compute the sample volumetric CTE from measured Δh(T) data as;

s (T) = fl (T) + Vc (c(T) - fl (T)) + d2cap [ ( h (T) / (T- Tref) ) - ho fl (T) ]

Vs

4 Vs

(7)

EXPERIMENTAL APPARATUS

Figure 1 illustrates the essential features of the test system. The cylindrical

cup containing the working fluid can be any non-reactive solid whose volumetric

CTE is known, such as quartz or aluminum. It is surrounded by rubber gaskets

and/or “O”-rings which are compressed by the demountable fixture. This consists

of two plates with four holes for steel bolts and nuts. Springs (not shown) help to

maintain compression of the plates against the cup. Temperature measurement to

±0.1K was carried out by cementing a thermocouple (T.C.) junction in a hole

drilled part way in the upper lid, within a few millimeters of the capillary also

cemented through the lid.. An additional thermocouple site can be placed in the

fluid to monitor thermal gradients. These are kept to within ±1K by controlling

3

the heating/cooling rate. When cooling with liquid nitrogen in the coils, it was

found that stirring the (antifreeze) cooling solution to promote uniform heat

transfer to the aluminum cup also stirred in the ice phase of the fluid, increasing

its viscosity and reducing the cooling rate. An unstirred solution allowed this

phase to precipitate on the coils and temperatures of < 200K could be reached

Figure 1 Schematic of volumetric CTE Apparatus. The fixture uses steel bolts to

compress the gaskets and the aluminum plates against the cup.

The working fluid in the cup can be any non-hazardous liquid which does not

decompose, vaporize, freeze or experience phase separation or excessive

viscosity. It should not react chemically with the sample. In addition , it should

have as small a volumetric CTE as possible, so that the measurement of relatively

small values of β (such as of metals) should not mean having to extract very

small changes due to the sample from large measured changes due to the working

fluid. Of 76 organic fluids listed in [14], less than 8 have β values below about

800 ppm/K; most are in the 1000-1500 ppm/K range. Ethylene glycol (C2H6O2)

and diethylene glycol (C4H10O3), the major constituents of common automobile

antifreeze have reported values of β of 626 and 635 ppm/K, respectively at about

293K. This suggests initial investigation of commonly obtained antifreeze

formulations. We note that the working fluid of the heating/cooling bath and in

the cup can be the same. However, the value of fl (T) must be measured first as

some antifreeze formulations contain additional corrosion inhibitors, water, etc.

Water is known to affect the density of ethylene glycol and its derivatives [15].

4

EXPERIMENTAL PROCEDURE

The capillary is cleaned by attaching a vacuum hose to the lid end and

immersing the other in deionized water, isopropyl alcohol, and/or methanol. The

rubber gaskets around the cup are compressed by the lid and held by the steel

fixture after the fluid and sample have been inserted. The excess fluid rises in the

capillary (the initial ho plus inactive fluid) so that sealing of one end is

unnecessary to draw in the fluid. Heat sealing (e.g. [11]) may damage test

material [2] and the open end also allows isobaric expansion conditions. Trapped

air bubbles are avoided by an overflow of the working fluid over the cup and

gaskets prior to lid compression. The assembled fixture is then placed in the

heating/cooling bath with LN2 copper cooling coils in a beaker on a hot plate.

The temperature is recorded after the meniscus in the capillary passes the

horizontal crosshairs of the telescope. (See also [16]). A leak in the system

negates the theory of constant mass above. This is easily checked by watching

the meniscus in the capillary for a time prior to measurement.

ERROR ANALYSIS

Sources of error are identified as follows:

1) Capillary Diameter The capillary used had an internal diameter varying from

535.0 to 536.0 microns over a 10 m length [17]. This translates into 0.1

microns over a range of h of 100 cm giving an error in s of about 0.8%

2) Uncertainty in ho. Equation 3 assumes that the total height of fluid ho in the

capillary is subject to the temperature change T. Depending on the geometry

of the system, this is normally true only for a few cm above the heating bath.

A typical value for ho then is 5 cm. An error of 1 cm here translates to < 1%

error in in a typical measurement of > 10oC.

3) Support system motion. Since the system is mounted on a hot plate or cooled

in a container, whereas the measuring telescope is not, the apparent h may

change due to the system motion relative to the measuring telescope. This

was checked by watching a mark on the capillary with the telescope

throughout a run. The maximum error over a 150oC excursion was 0.01cm.

4) Verticality of the capillary. It the telescope scale and capillary are not

mutually parallel, there is a cosine error due to any angular () deviation from

the line of the telescope scale. The true h = the apparent h / (cos ). This

is easily measured with a protractor across the beaker and generally varies

between 0 and 15o.

5) Thermal Gradients.

These are caused mainly by the finite thermal

conductivity of the working fluid (and possibly sample) and result in a slight

hysteresis when reversing the heating/cooling direction. For maximum

5

accuracy, it is necessary to measure the fluid alone and the fluid plus sample

at the same fluid composition, heating or cooling rate and over the same

temperature range.

TYPICAL RESULTS

A series of tests was undertaken to assess the validity of the theory. The Al

cup dimensions were 2.26 cm internal diameter and 1.864 cm high. The ratio of

Vs/Vc was varied for a relatively low CTE material, namely steel, by measuring

different numbers of steel balls placed in the aluminum cup. Initially the

antifreeze fluid was measured. A linear regression of the data gave Δh = 1.0921

deg C –25.245 with correlation coefficient R2 = 0.9962. Use of Equation 6

converts this to βfl = 399.72 x 10-6/K.

Figure 2 Change in capillary meniscus level with temperature for working fluid

alone and for different relative volumes of a low carbon steel sample.

The solid lines in Figure 2 compare the experimental data with Δh predicted

from this linear regression curve and from Equation 5 assuming the volumetric

CTE of steel is 35.1 x 10-6/K. Agreement is seen to be excellent for all cases, so

that the Δh data can correspondingly be used to predict βs according to Equation

7. However, the βfl value is not constant to lower temperatures. A typical

polynomial fit of the data gave;

Δh (cm) = -7e-6 T4 –0.0004 T3 – 0.0123T2 + 1.3792 T – 18.38

(8)

in the region 210K < T < 283K with R2 = 0.9973. This trendline is superimposed

on the fluid data in Figure 3. Fluid data were then used to predict the results for

different Vs/Vc values on cooling and these curves are shown to lie closely over

6

the data in Figure 3. In the case of Vs/Vc = 0.248, data were continued cooling

from higher temperatures and prediction using a fixed βfl of 399 x 10-6/K gave a

good prediction down to about 283K. Below that Equation 8 was used.

Figure 3 Cooling data for samples of Figure 2. A polynomial fit is made to the

fluid data which is then used to give the predicted (line) data for the steel samples.

DISCUSSION

A parametric analysis of Equation 7 suggests that for maximum resolution, Vs

must Vc especially if s << fl. Eq.7 consists of three terms, the first and

third positive, he second negative. To maximize the effect of the Δh measurement

and to minimize the effect of the second term, Vs/Vc again should be as large as

possible. Equation 7 can be used to estimate the relative importance of fluid

expansion. For example, if we consider the parameters used in Figures 2 and 3,

with Vs/Vc = 0.489, ΔT = 50K, ho = 5 cm, dcap = 0.053cm, βfl = 399 x 10-6/K, and

βs = 35.1 x10-6/K (for steel), we predict a Δh of 28.47cm. However, if we

measure this value of Δh but the βfl were 401x10-6/K, we would deduce that the

steel had a βs of 34.75 x 10-6/K.

There are several ways in which the data can be analyzed for greater accuracy.

A fourth order polynomial such as Equation 8 has limitations in predicting the

meniscus level, e.g. when steel and brass cylinders are cooled. One possibility for

greater accuracy is to use an F-test (available on MS Excel) together with a

polynomial for the fluid. This calculates the one-tailed probability that the

variances in two data sets are not significantly different. Thus one can insert

different values of βs into Equation 5 and compare that data set with the

measured one. A maximum (0.9589) for the F-test occurs with βs equal to 36.1 x

10-6/K as compared to 0.9133 for βs = 35.1 x 10-6/K or 0.9534 for βs = 38.1x 10-

7

6

/K. The value of 36.1 x 10-6/K compares favorably with the low temperature

data of [18].

This method has the capability to measure the volumetric CTE of arbitrarily

shaped samples such as gels, waxes, and greases. However, the working fluid

must not react with the sample. Consequently, other fluids are being sought. We

have studied perfluoro compounds, water, synthetic motor oils, machine oils,

alcohol based compounds, and glycols. Perfluoro compounds with 12 carbons

such as the 3M “Fluorinert” series are inert with some gels and appear to have a

linear beta on the order of 1200 ppm/C. They also have the advantage to protect

many ceramic and optical crystals from reactions with moisture. Water has a low

value of βfl near room temperature but it increases rapidly with temperature and is

very non-linear. Low viscosity synthetic motor oils are less successful due to

poor wetting of the capillary. Some alcohol based fluids, e.g. brandy, leave

residues after moving up and down a capillary.

Relatively pure (99%+) ethylene and diethylene glycol show closely similar

behavior (Figure 4). Figure 5 shows the instantaneous volumetric expansion

coefficient as a function of temperature for ethylene glycol. The scatter in the data

points reflects the use of various heating/cooling rates. The relatively low β

values of the glycols suggested study of propylene glycol (C3H8O2), whose

advantages include greater safety and possible supercooling of the liquid to below

200K. It boils above 460K. However, we found considerable variability from test

to test, possibly because of the dipotassium phosphate and deionized water

contained in the “inhibited” version tested. Besides pure polypropylene glycol,

we are investigating silicone based fluids, such as polydiethylsiloxanes with

viscosities on the order of 10 centistokes and molecular weights on the order of

400 – 500 .These can also be used over the range 200-400K.

Figure 4 Relative displacements of meniscus in a 0.053 cm I.D. quartz capillary

with temperature for ethylene glycol (upper curve) and diethylene glycol.

8

Figure 5 Instantaneous volumetric expansion coefficient for 99%+ ethylene

glycol versus temperature

SUMMARY

Major advantages and features of this inexpensive, completely reusable

dilatometer are summarized as follows:

1)

2)

3)

4)

5)

No heat sealing or mercury is required.

The dilatometer is demountable and the same system can be used for many

liquid, solid or mixed phase samples, including powders, gels, waxes, etc.

Accuracy and resolution are enhanced by use of statistical analyses of the

data, such as a statistical F-test.

The available temperature range is limited by the properties of the

working fluid and is about 200- 350K with common antifreeze

formulations at 1 atm pressure. Higher temperatures are possible with pure

glycols and possibly silicone based fluids.

Any size/shape sample can be measured as long as it fits into a cup with

accurately determinable internal volume and expansion coefficient. A high

CTE metal such as aluminum is easily machined, its expansion reduces

h for a given temperature range and a high thermal conductivity

promotes accurate sample temperature measurement.

ACKNOWLEDGMENTS

9

The author is grateful to the staff of Precision Measurements and Instruments

Corporation for helpful suggestions and technical assistance, in particular,

Benjamin Nielsen, James Sharp and Don Schneider.

REFERENCES

1) N. Bekkadahl J. Res. Natl. Bur. Stand. Vol. 42, p145 (1949)

2) J.E. McKinney and R.W. Penn. “Composite Dilatometer for Measuring Density of Liquids

and Solids” Rev. Sci. Intrum Vol. 43, p1211 (1972)

3) M. Obama, Y. Oodera, N. Kohama, T. Yanase, Y. Saito and K. Kusano “Densities, Molar

Volumes and Cubic Expansion Coefficients of 78 Aliphatic Ethers” J. Chem. Eng. Data Vol.

30 pp1-5 (1985)

4) Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by

Lipkin Bicapillary Pycnometer” ASTM D 941-88

5) S.B. Aznarez, L. Mussari and M.A. Postigo “Temperature Dependence of Molar Excess

Volumes for the Dimethyl Sulfoxide + Thiophene System an Thermal Expansion

Coefficients between 293.15 and 313.15 K” J. Chem Eng. Data Vol. 38 , pp270-273 (1993)

6) Standard Test Method for Density, Relative Density (Specific Gravity) of API Gravity of

Crude Petroleum and Liquid Petroleum Products by Hydrometer Method” ASTM D 1298-99

7) A. Guillot and P. Dantzer “Determination of Volumes by Gas Expansion” J. Phys. E: Sci.

Instrum. Vol. 19 (1986)

8) J. Ortega “Densities and Thermal Expansivities of Hexanol Isomers at Moderate

Temperatures” J. Chem and Eng. Data Vol. 30, No.1 pp5-7 (1985)

9) A.T. Parsons and C.M. Balik “Composite Dilatometer for Polymer Thin Films” Rev. Sci.

Instrum. Vol. 60 p219 (1989)

10) C.M. Sorensen “Densities and Partial Molar Volumes of Supercooled Aqueous Solutions” J.

Chem. Phys. Vol 79(3) pp1455-1461(1983).

11) P. Westh, “Thermal Expansivity, Molar Volume and Heat Capacity of Liquid Dimethyl

Sulfoxide-Water Mixtures at Subzero Temperatures” J. Phys. Chem Vol. 98, pp3222-3225

(1994)

12) D. Bulone, I.D. Donato, M.B. Palma-Vittorelli and M.U. Palma “Density, Structural

Lifetime, and entropy of H-bond cages Promoted by Monohydric Alcohols in Normal and

Supercooled Water” J. Chem. Phys. Vol. 94 No. 10, pp6816-6819 (1991)

13) E. P. Papadakis “Tabulation of the Coefficients of a Quadratic Function for the Thermal

Expansion of Various Alloys and other Engineering Materials” Materials Science and

Engineering Vol. 10 p195-203 (1972)

14) CRC Handbook of Physics and Chemistry, p 6-140 85th Edition,

(2004- 2005) D.R. Lide, Editor-in-Chief, CRC Press LLC, (2004) p6-140

15) K. Kusano, “Densities, Refractive Indexes, and Normal Boiling Points of 1,2-Disubstituted

Ethylene Glycol Derivatives J. Chem & Eng. Data Vol. 23, No. 2 pp141-143 (1978)

16) D.W. Guillaume, M. Norton and D. DeVries “Dimensional Considerations for Small-Bore

Manometers” Rev. Sci. Instrum. Vol. 60 (9) pp3062 –3064, (1989)

17) Polymicro Technologies, LLC , 18019 N. 25 th Avenue, Phoenix, AZ 85023-1200 ,

www.polymicro.com

18) TPRC Thermophysical Property data Series (CINDAS), Purdue University

10