Microcentrifuge - School of Chemistry

advertisement

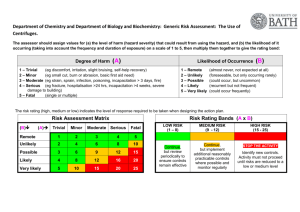

STANDARD OPERATING PROCEDURE SP # APM017 Page 1 of 4 Version: 1.0 Date: 27/07/10 Revise by: 27/07/13 Replaces: N/A Written by: Dana Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne USE OF MICROCENTRIFUGE 1. Introduction This SOP discusses the procedure and safety guidelines for the use of the Hermle Z 233 M-2 microcentrifuge. A laboratory centrifuge is an apparatus used in the laboratory for separating substances of different density or particle size, when suspended in a fluid, by spinning them about an axis in a suitable container. These samples are placed into and are spun in a rotor, which is the primary component that holds the material to be subjected to centrifugal force (in some form of tube/container) and which is rotated by the drive system 2. Scope This procedure applies to all staff, students and visitors of the Advanced Porous Materials Group in the school of Chemistry at the University of Melbourne that work in the laboratory and have the potential to use the centrifuge 3. Safety Only trained laboratory personnel can operate the instrument. Personal protective equipment (PPE) including safety glasses or face shield and laboratory coat must be worn when using or handling centrifuge equipment. Do not centrifuge materials capable of developing flammable or explosive vapours (e.g. chloroform or ethyl alcohol) nor handle or store them within a 30 cm clearance envelope surrounding the centrifuge. Do not spin samples which can chemically react with each other when exposed to air. Use only Hermle rotors and accessories designed for use in the microcentrifuge. Before starting the microcentrifuge, make sure that rotor is securely connected on the rotor nut. Do not exceed the maximum rated speed (14000 rpm) of the rotor in use. Make sure that filled containers are loaded symmetrically into the rotor and that opposing bottles or tubes are filled to the same level with liquid of the same density. i.e. ensure the rotor is balanced. It is strongly recommended that all microcentrifuge containers are capped and not overfilled, to prevent leakage. Plastic containers have been microcentrifuge tested for use at temperatures between 2 and 25 ºC. Do not lift or move the microcentrifuge while the rotor is spinning. Never attempt to override the door interlock system while the rotor is spinning. In the event of a power failure, do not attempt to retrieve the sample from the microcentrifuge for at least one hour. STANDARD OPERATING PROCEDURE SP # APM017 Page 2 of 4 Version: 1.0 Date: 27/07/10 Revise by: 27/07/13 Replaces: N/A Written by: Dana Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne 4. When glass tubes are run, be careful if these tubes break inside the chamber bowl. Examine and clean the gasket and/or chamber bowl with care because glass fragments may have become embedded in them. If a glass bottle or tube breaks, remove the glass very carefully from the rotor. Imbedded glass particles that remain in the rotor cavities or adapters can cause tube failure during subsequent runs. Clean the rotor thoroughly immediately following a bottle or tube breakage. If pathogenic, toxic, or radioactive samples are intended to be used in the microcentrifuge, it is the responsibility of the user to ensure that all necessary safety regulations, guidelines, precautions, and practices are adhered to accordingly. Licences and Permits N/A 5. Training and Competency A first time user can be trained and temporarily supervised by a senior member of the research group (who is a trained in using the microcentrifuge) until observed to be competent in using the microcentrifuge. No competency records required. 6. Risk Assessments Refer to the following risk assessment forms: Use of centrifuge, assessed 19/07/10. Use of electrically operated equipment, assessed 20/06/07. Waste solvent disposal, assessed 09/11/09. 7. Equipment and Maintenance / Handling and Storage / Labelling Maintenance: The maintenance of the microcentrifuge essentially involves keeping the rotor chamber, the rotor and the accessories clean. Use only neutral cleaning products (pH 6–8). Do not use sharp tools on the rotor, as they can scratch the anodized surface. Corrosion begins in scratches and may open fissures in the rotor with continued use. Periodically (at least monthly) inspect the rotor, especially inside cavities, for rough spots, cracks, pitting, white powder deposits, or heavy discoloration. If any of these signs are evident, do not run the rotor. Wash the rotor and rotor components immediately if salts or other corrosive materials are used or if spillage has occurred. Do not allow corrosive materials to dry on the rotor. Airdry the rotor upside down. Do not use acetone to dry the rotor! Regularly treat all anodized aluminium parts with anticorrosion oil. If condensation forms within the rotor chamber, gently clean with a cloth. STANDARD OPERATING PROCEDURE SP # APM017 Page 3 of 4 Version: 1.0 Date: 27/07/10 Revise by: 27/07/13 Replaces: N/A Written by: Dana Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne Storage: When the rotor is not in use, store it in a dry environment (not in the microcentrifuge). 8. Operating Procedures 1. With the power switch on, press [ ] to open the chamber door. 2. Load the samples into the rotor. Always run the rotor with a balanced load. Close the chamber door. 3. Set the run parameters as outlined below: 4. Close the centrifuge lid (green light illuminates). 5. Press [Start]. 6. Allow the set time to count down to zero, or end the run by pressing [Stop]. 7. When the rotor stops spinning, press [ ]. Unload the rotor. Figure 1. Image of microcentrifuge indicating the location of buttons and dials. Presetting run conditions (chamber door open): 1. Set run speed using the speed dial, selecting between rpm and rcf by pressing [Speed/rcf]. The set speed will be illuminated in the speed display. 2. Set run duration using the time knob. Times between 1 and 60 minutes and hold can be selected. The set time (time remaining) will be illuminated in the time display. 3. For a continuous run (hold), turn the time dial clockwise to the limit stop. Two minus signs (–) will be illuminated in the time display. The duration of a continuous run can be checked mid run by pressing [Start]. 4. The brake intensity and acceleration can be changed by pressing [Fast/Slow]. If the green “fast” control lamp is lit, the unit accelerates and decelerates fast. If the green “slow” lamp is lit, the unit accelerates and decelerates very slowly. Changing run conditions during run (chamber door closed): 1. Change run speed by holding [Preset] at the same time as adjusting the speed dial. The new run speed is set once [Preset] is released. STANDARD OPERATING PROCEDURE SP # APM017 Page 4 of 4 Version: 1.0 Date: 27/07/10 Revise by: 27/07/13 Replaces: N/A Written by: Dana Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne 2. Change run duration by holding [Preset] at the same time as adjusting the time dial. The new run duration is set once [Preset] is released. 3. Change brake intensity and acceleration by pressing [Preset] at the same time as [Fast/Slow]. Short runs: 1. For short centrifuge runs the [Quick] key may be used. The centrifuge starts and will remain running as long as the [Quick] button is pressed. The operating time will be indicated in seconds in the time display. 9. Controls and Calibrations This instrument or any component of this instrument is not to be used to calibrate other equipment. No component of the microcentrifuge requires calibration. 10. Waste Disposal Solvent Disposal: Dispose of solvents in the appropriate waste container (e.g. Water soluble waste solvent, water insoluble waste solvent, halogenated waste solvent). Glass Disposal: All broken, irreparable glassware should be rinsed and disposed of in the designated glass bin. 11. Relevant Documents / References Hermle Operation Manual and Catalogue: Instruction manual for microcentrifuge Z 233 M-2. Hermle LaborTechnik, Microliter centrifuges, Version 1, ALYS Labware. 12. Signage / Summaries / Templates N/A 13. Appended Material N/A