Abstract - Academia Sinica

advertisement

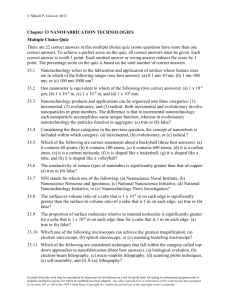

研究計畫名稱:先進奈米壓印顯微術之研究 論文名稱:利用高分子膠體奈米顆粒製造大範圍週期性奈米壓印之 模具 作者:卓奕弘(Yihong Cho)、陳培菱(Peilin Chen) 聯絡人:陳培菱 通訊地址:中央研究院 應用科學及工程研究所籌備處 電話:(02)27898000 傳真:(02)27826680 e-mail:peilin@gate.sinica.edu.tw 1 Fabrication of Large-Area Periodic Nanopillar Arrays for Nanoimprint Lithography Using Polymer Colloid Masks** Yi-Hong Cho, Peilin Chen Institute of Applied Science and Engineering Research, Academia Sinica. 128, Section 2 Abstract A novel scheme for the fabrication of large-area nanoimprint stamps has been developed based on the utilization of a combination of nanosphere lithography and reactive ion etching. Both single and double layer polystyrene beads have been employed to construct well-ordered, periodic silicon nanopillar arrays. The nanopillar arrays fabricated by this method have been successfully used as the stamps for nanoimprint lithography. Our result indicates that this approach is capable of producing large-area sub-50 nm periodic nanostructures. Introduction Periodic nanostructures are of great research interests, because of their potential applications in photonic crystals [1-3], data storages [4-6] and biosensors [7-8]. To realize such opportunity, it requires the development of lithography techniques, which are capable of fabricating large-area periodic nanostructures with reasonable control of their size and periodicity. Present commercial optical lithography allows mass-replication of nanostructures with ~130 nm resolution and is approaching its limit set by diffraction (~110 nm for UV light with a wavelength of 193 nm)[9]. To fabricate nanostructures in the sub-100 nm region, different techniques such as electron-projection and extreme-ultraviolet lithography are under development. However, the cost and progress of these systems may prevent their immediate utilization. Therefore, lots of recent research efforts have been focused on the development of alternative cost-effective, high-throughput, high-resolution lithography techniques for both industrial applications and fundamental studies. Among these approaches, 2 nanoimprint lithography is one of the most promising schemes for large-area mass-replications. It has been demonstrated [10-12] that nanoimprint technique is capable of replicating large-area nanostructures with feature size smaller than 10 nm and the imprint time can be as fast as a few hundred nanoseconds. Despite of these promising results, there are still technical challenges remained to be solved such as sticking between stamp and polymer layer [13] and the influence of visco-elasticy behavior of polymer on the imprinted results [14]. Therefore, it is very important to conduct researches on many fundamental aspects of nanoimprint lithography. However, the fabrication of stamps for nanoimprint lithography requires e-beam lithography, which limits the accessibility of nanoimprint technique. Here we report a simple stamp fabrication technique that is capable of producing large-area, well-ordered, periodic nanopillars for nanoimprinting with sufficient size control in the sub-50 nm region. Experimental The detailed procedure of fabricating large-area periodic nanopillar arrays as stamps for nanoimprint lithography is illustrated schematically in figure 1. Silicon substrates are first coated with monodispersed polystyrene solution to form large-area close packed structures on the surfaces. Depending on the concentration and speed of spin-coater, single layer or double layer polystyrene template can be obtained. Since the double layer template produces periodic structures that are more suitable for commercial applications (fig 1a), we will focus our discussion on the features created by the double layer templates. In the second step, a metal film is deposited on the double layer template and the polystyrene beads can be dissolved in CH2Cl2 solution leaving periodic metal arrays on the surface (fig 1b). These periodic metal arrays then serve as the etching masks in the reactive ion etching process. By placing the silicon substrates in a reactive ion etcher, large-area silicon nanopillar arrays can be obtained (fig. 1c). To conduct nanoimprinting experiment, the silicon nanopillar array is pressed at high pressure against a poly (methyl methacrylate) (PMMA) film on a silicon wafer at temperature higher than the glass transition temperature of PMMA (fig1. d). After removing the nanopillar stamp, the silicon wafer is first etched in oxygen plasma to remove residual PMMA in the imprinted holes and further deposited with desired materials (fig1. e). After lift-off process, periodic arrays of desired materials can be obtained (fig1. f) To demonstrate that the nanopillar arrays prepared by nanosphere lithography is suitable for nanoimprint lithography, we have utilized 150 nm tall silicon nanopillar arrays fabricated by 350 nm polystyrenes as the stamps for nanoimprinting. In this experiment, a 200 nm thick 950K PMMA film was spun on a silicon substrate and baked 3 in a vacuum oven at 1200C for 10 minutes. Both PMMA and nanopillar arrays were heated to 2000C and then compressed in a hydraulic press at a pressure about 135 kg/cm2 for 5 min. The press was released when the temperature dropped below the glass transition temperature of PMMA, 1050C. Each stamp has been used for nanoimprinting at least for twenty times. No noticeable pattern degradation or damages on the stamps were observed. Figure 2a shows the SEM image of the nanoimprint stamp prepared by nanosphere lithography using 350 nm polystyrene beads. The lateral dimension of the triangle nanopillars was around 65 nm. The result of nanoimprinting is shown in fig 2b. Then a 20 nm thick chromium film was deposited on the top of PMMA. The lift-off process was performed by placing the silicon substrate in acetone and sonicating for 3 to 5 minutes. Fig 2c and fig 2d exhibit the SEM images of well-ordered periodic nanodots after lift-off process. The diameters of nanodots were slightly less than 50 nm. This result confirms that our method is capable of fabricating large-area sub-50 nm periodic nanostructures. It is interesting to note that the nanoparticles formed by nanosphere lithography are triangular in their shape while the subsequent template produces circular nanodots through nanoimprinting. This is probably due to the fact that the nanopillars fabricated by this scheme are cone-like pillars with round tips. One remarkable feature of our approach is that the size of nanopillars could be reduced by various techniques such as ashing and trimming [15]. Therefore, the size and separation of periodic nanostructures can be independently adjusted. Shown in figure 2e is one example of using size-reduced nanopillar for nanoimprinting. In this case, the size of nanopillars was reduced by chromium etchant. The lateral dimension of imprinted holes was less than 30 nm. Other approaches for size reduction are currently under investigation in our group. Conclusions we have developed a low-cost, high throughput fabrication process for producing large-area, well-order periodic nanopillars for nanoimprinting with feature size less than 50 nm that would allow easily accessing the nanoimprinting technique without the need of e-beam lithography. When these stamps were used in nanoimprint lithography, large-area periodic nanostructures with lateral dimension less than 30 nm have been obtained. The size and separation of the fabricated periodic nanostructures can be independently adjusted by selecting different diameters of polystyrene beads in the nanosphere lithography and trimming the nanopillars with various size reduction techniques, respectively. The shape of nanostructure can be also modified by using different combinations of metal masks and etching recipes. Acknowledgements This research was supported in part by National Science Council under contract 91-2113-M-001-021. Figure 1. Illustrations for the fabrication of large-area periodic nanostructures by a combination of double layer nanosphere lithography and nanoimprint lithography. Figure 2. (a) SEM image of a nanoimprint stamp fabricated by a 350 nm polystyrene template. (b) The imprinted patterns on PMMA. The base of triangular hole is about 55 nm. (c) Large-area imaged of periodic metal dots formed by nanoimprint lithography. (d) SEM image of nanodots formed by nanoimprint lithography. The diameters of nanodots are around 50nm. (e) SEM image of the imprinted patterns using stamp treated with chromium etchant. The lateral dimension of triangular holes is about 30 nm. Figure Captions References: 1. V.V. Poborchii, T. Tada, T. Kanayama, Appl. Phys .Lett., 1999, 75, 3276. 2. S.M. Yang, G.A. Ozin, Chem. Comm., 2000, 24, 2507. 3. M.C. Wanke, O. Lehmann, K. Muller, Q. Wen, M. Stuke, Science, 1997, 275, 1284. 4 4. J.Y. Cheng, C.A. Ross, V. Z.-H. Chan, E.L. Thomas, R.G.H. Lammertink, G.J. Vancso, Adv. Mater., 2001, 13, 1174. 5. M. Hehn, K. Ounadjela, J.-P. Bucher, F. Rousseaux, D. Decanini, B. Bartenlian, C. Chappert, Science, 1996, 272, 1782. 利用高分子膠體奈米顆粒製造大範 圍週期性奈米壓印之模具 6. P.R. Krauss, S.Y. Chou, Appl. Phys. Lett. 1997, 71, 3174. 卓奕弘、陳培菱 7. A.J. Haes, R.P. Van Duyne, J. Am. Chem. Soc., 2002, 124, 10596. 8. K.-B. Lim, S.-J. Park, C.A. Mirkin, J.C. Smith, M. Mrksich, Science, 2002, 295, 1702. 9. R.F. Pease, Nature, 2002, 417, 802. 10. S.Y. Chou, P.R. Krauss, P.J. Renstrom, Science, 1996, 272, 85. 11. S.Y. Chou, P.R. Krauss, W. Zhang, L. Guo, L. Zhuang, J. Vac, Sci. Technol. B, 1997, 15, 2897 12. S.Y. Chou, C. Keimei, J. Gu, Nature, 2002, 417, 835. 13. M. Beck, M. Gracyk, I. Maximov, E.-L Sarwe, T.G.I. Ling, M. Keil, L. Montelius, Microelectron. Eng. 2002, 61, 441. 14. S. Zankovych, T. Hoffmann, J. Seekamp, J.-U. Bruch, C.M. S. Torres, Nanotechnol., 2001, 12, 91. 15. K. Asano, Y.-K. Choi, T.J. King, C. Hu, IEEE Trans. Electron. Dev., 2001, 48, 1004. 5 中央研究院 應用科學與工程研究所籌備處 摘要 大範圍週期性的奈米模具製造技術已 經結合了奈米球微影術與離子反應蝕刻製 作;而單、雙層之高分子球也被利用於週 期性的矽柱陣列。矽柱陣列的製造也成功 的在奈米壓印使用。經本實驗室之研究可 製做出低於 50nm 以下大範圍週期性之奈米 結構。