Solvent Stores - University Wiki

advertisement

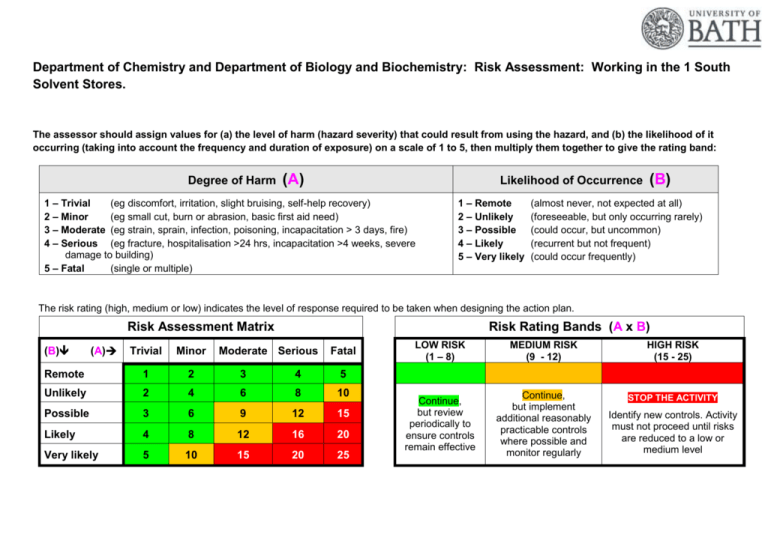

Department of Chemistry and Department of Biology and Biochemistry: Risk Assessment: Working in the 1 South Solvent Stores. The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (B) (almost never, not expected at all) (foreseeable, but only occurring rarely) (could occur, but uncommon) (recurrent but not frequent) (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Moderate Serious Fatal Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but review periodically to ensure controls remain effective Continue, but implement additional reasonably practicable controls where possible and monitor regularly STOP THE ACTIVITY Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Risk Assessment of: Solvent Storage. Assessor(s): Marianne Harkins Work Authorised by: Overview of activity / location / equipment / conditions being assessed: Working in the 1 South solvent stores at the University of Bath. Date: March 2015 1 South 0.66 Mixed solvents/ 1 South 0.65 Acetone. Hazard Who could be harmed? How could they be harmed? General Laboratory users, staff, support staff, PG and students, and/ or contractors to the laboratory. See below for specific details. Control measures needed to minimise risk Anyone accessing the solvent store or passing the solvent store. Spills: Solvent spillage could potentially result in an Solvent bottles could be dropped or could crack, Risk after controls implemented A B AxB Solvents will be kept in original containers where possible. If not possible they will be kept in a suitable alternative with a secure leak-proof lid. Vented caps are to be used on storage bottles where provided by manufacturers. All solvents are to be correctly labelled including name of contents and hazards. When not in use, lids must be replaced immediately. Suitable carriers must be used for transport. These can be borrowed from the 3 South stores. Work with the door open, but close and lock upon exit. All obvious ignition sources must be removed. Risk Assessment specified PPE must be worn at all times (nitrile gloves EN374, safety glasses EN166 & lab coat). Report to your employer any damaged or defective ventilation plant or personal protective equipment (PPE). Locate your nearest eyewash station before starting work. No eating or drinking in laboratories or in the Solvent Store. Wash thoroughly after working with solvents and before eating or smoking. Do not smoke, weld, burn or use any naked lights in areas that may contain the vapour of chlorinated solvents as ver y toxic gases may be given off. Stock will be kept to a minimum. Solvents must not be dispensed or opened in the store. Dispensing should be carried out in a lab. The condition of bottles/ labels will be checked on a regular basis by 5 1 5 explosive atmosphere. Splashes/ Spills: Exposure to hazardous substances. Skin and/or eye contact. Inhalation/ infection. Fire: Burns/ smoke inhalation or death. Damage or loss of infrastructure. resulting in spillages. Solvents could also be spilt during the dispensing process. Explosion/ fire could result in burns/ smoke inhalation/ blast related injuries Solvent could splash or spray onto skin or into eyes. There could be contact/ inhalation A fire could break out in or around the solvent store. Solvents could ignite if exposed to a naked flame or spark. Burns/ smoke inhalation/ blast related injuries No dispensing will be carried out in the solvent store. Use automated handling, or using tools rather than hands when using solvents. Use procedural controls, eg barriers or splashguards, and restricting access Do not use solvents to remove paint, grease etc from your skin. 3 1 3 All combustible materials will be removed from the solvent store as a matter of priority. The Solvent Store has spark proof lighting installed. The nearest fire extinguisher is located in the yard. The nearest fire break-glass point is located in the yard or just inside 1 South (Corridor O.9). Our fire systems are regularly maintained and checked by our Estates Department. Regular health and safety inspections are carried out, including the Solvent Store and any issue4s or problems are dealt with. The Solvent Store is locked out of hours. Safety signage is situated around the store prohibiting the fact that no naked flames or other sources of ignition are to be used in or around the store. 5 1 5 Ensure that good housekeeping is observed at all times. 4 1 4 All rubbish must be removed immediately. The floor and area outside the solvent area must be kept clear of solvent bottles. Walkways and access routes must be kept clear at all times. Solvents must not be stored on the floor. Slips and Trips: musculoskeletal injury. Dropped solvent bottles. Poor housekeeping could results in slips and trips in the solvent store and slip/ trip/ fall related injuries stores staff (product cycle should be used so old stock is used first). Gloves must be removed & disposed of upon completion of work before leaving the area, to avoid contaminating other areas (such as door handles, computers, etc.). No access out of hours to the Solvent Store. Spill kits are available in the Solvent Store and will be used or latget spills e.g 2.5 L bottle. Only appropriate trolleys borrowed from the stores in 3-South will be used to transport solvents.