The September 2012 Conference Call is

advertisement

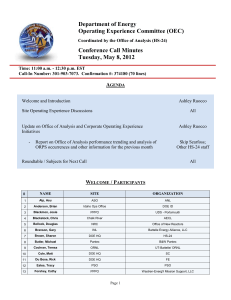

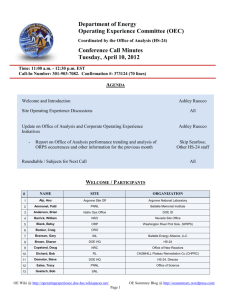

Department of Energy Operating Experience Committee (OEC) Coordinated by the Office of Analysis (HS-24) Conference Call Minutes Tuesday, August 21, 2012 Time: 11:00 a.m. - 12:30 p.m. EST Call-In Number: 202-287-5323 AGENDA Welcome and Introduction Ashley Ruocco Site Operating Experience Discussions All External Organizations Operating Experience and Lessons Learned Discussion All Update on Office of Analysis and Corporate Operating Experience Initiatives Ashley Ruocco Discussion of and request for information about fall meeting of the ORPS and OE Committees All Roundtable / Subjects for Next Call All PARTICIPANTS # NAME SITE 1 Abston, Lee Ann OR-Isotek 2 Alp, Asu Argonne Site Off 3 Barrick, William NSO 4 Bentley, Jeff DOE-SRS 5 Blackstock, Chris Atomic Energy of Canada, Ltd 6 Blank, Betsy ORP 7 Booker, Craig ORO 8 Branson, Gary INL 9 Brown, Sharon DOE HQ 10 Cheng, Sam LASO 11 Cochran, Teresa ORNL 12 Cole, Matt DOE-HQ 13 Cummings, Danae NVSO 14 Dayani, Mosi Savannah River Site 15 DuBose Rick DOE-HQ-FE Page 1 # NAME SITE 16 Daugherty, Paul DOE-SRS 17 Ferguson, Scott Atomic Energy of Canada, LTD 18 Harris, Allan EMCBC 19 Hauptmann, Michael. BNL 20 Heeter, Tom OR-Isotek 21 Heller, Sara NTS-NSTec 22 Horning, Jeff LLNL 23 Hubbard, Chelsea DOE-OR 24 Hutto, Rod SR 25 Innocent, Jessy DOE NNSA 26 Ito, Fran WIPP 27 Johnson, Angela SRS 28 Johnson, Thomas EM-54 29 Jolly, Debora PPPO 30 Langstaff, David RL 31 Landmesser, Jim EM-41 32 Lee, John EM-54 33 Lin, Paul DOE HQ 34 Lopez-Cardona, Emma DOE HQ 35 McDuffie, Steve Hanford 36 Mc Vey, James WSMS 37 Menas, Matt NETL 38 Miehls, Dennis WIPP 39 Minton, Lauri Pantex 40 Natoli, Ross DOE HQ 41 Navarette, Martin WIPP 42 Neil, Dave Idaho Operations Office 43 Neilson, Steve Thomas Jefferson Site Office 44 Norbury, Michael DOE HQ 45 Orr, Jane SHAW VCR Project 46 Patel, Jay NRC 47 Pavalko, Kelly NTS 48 Pearson, John ORAU 49 Polanish, Caroline BHSO 50 Price, Stephanie WSI/SRS 51 Rao, Nimi DOE HQ 52 Robison, Camille INL/AMWTP 53 Ruocco, Ashley DOE HQ 54 Sanchez, Ruben DOE HQ 55 Schutt-Bradley, Joanne OR/ETTP 56 Searfoss, Glenn DOE HQ 57 Shidal, Suzanne PPPO 58 Sivak, Andy NETL Page 2 # NAME SITE 59 Smith, Duane Oak Ridge - TRU Project 60 Smith, Kathleen Atomic Energy of Canada, LTD 61 Stolte, Bruce NSO 62 Stuewe, Robert LANL 63 Tamplain, Jeffrey SPRO 64 Thomason, Gail PEC 65 White, J.D. PPPO 66 Whitley, Daniel PPPO 67 Weibel, Marc SLAC 68 Williams, Tom E. NA-1 69 Zabel, Jennifer Golden Field Office WELCOME AND INTRODUCTION Ashley Ruocco – Ruocco welcomed all to the call and introduced those at HQ in Germantown. HIGHLIGHTED PRESENTATION The presentation was rescheduled to the September meeting: Mild Electrical Shock During Usage of Portable Office Heater by Paul Daugherty, Savannah River Site. Mr. Daugherty will provide additional information that is posted on the OE Wiki regarding the topic. SITE OPERATING EXPERIENCE DISCUSSIONS 1. Brookhaven Site Office / Brookhaven National Lab (BNL) Hauptmann reported on four lessons learned from the recent ladder fall event: o On a vertical ladder, because the worker’s center of gravity is away from the ladder, the worker is more likely to fall than on an inclined ladder where the worker can stay upright. o Vertical ladders should only be used for access, not work. o The 1968-era ladder was manufactured to codes in effect at the time but did not meet current codes (OSHA and 861), especially in the area where the ladder met the roof. o Workers must communicate about perceived dangers as well as real ones. In this case, several workers had been uncomfortable with the way they had to transition from the ladder to the roof, but they had not said anything, assuming that “that’s the way it is.” After the worker fell, there was a general realization that there needed to be more open communication/sharing. 2. Carlsbad Field Office/WIPP During a recent emergency, non-essential personnel remained in the area despite being requested to evacuate, and they used personal cell phones to discuss the situation. As a result, patient privacy was compromised. Page 3 3. Los Alamos Site Office (LASO) / LANL 4. 5. 6. 7. 8. Lesson learned: don’t think your injury prevention and reporting efforts are failing because reporting rates rise in the first year and then fall. After focusing on repetitive motion trauma in office settings, LANL moved injury reduction efforts to glovebox operators. Reports doubled during the first year when improvements were being made, but then fell 20% in the second year. The LL from this is that increased reporting is a result of workers’ awareness and so it is important to look at multi-year data. LANL’s next efforts will be to work with body positioning and reduce push-pull injuries. Livermore Site Office (LSO)/ LLNL Pressurized System Calibration lesson learned was submitted about a calibration device that broke when exposed to high pressure. Fortunately, the device was aimed downward and no injuries resulted. To relieve high pressure, workers had loosened the nut/cracked the fitting, but that action may have left the fitting vulnerable when pressure was increased. LL is to inspect all fittings to ensure that they’re tight. KSO / KCP Nothing to report National Energy Technology Lab (NETL) In June a forklift mast struck a partially-closed bay door when a worker attempted to bring a table into the building and the door was not fully open. There was significant damage to the door and tracks but there were no injuries or damage to the forklift. The operator had completed forklift training and a recent refresher but may have been distracted by the extreme heat (105°). Nevada Site Office (NSO) / NST / NSTec No LL to report. NST’s self-assessment IAW Order 210.2A is not complete but the results will be shared. Oak Ridge Site Office (OR) / Oak Ridge National Lab (ORNL) Lessons Learned has been submitted to the database: recognize changing conditions to prevent lead exposure. 9. Princeton Site Office (PSO) Ruocco presented for Tracy Estes Discharge of Halon System in NSTX Control Room On August 13, 2012, the Halon 1301 System in the National Spherical Torus Experiment Control Room discharged. The alarm bells did not alarm and were manually initiated to evacuate the building. No personnel were in the Control Room/Annex at the time. Emergency Services personnel entered the control room to assess the situation and the ventilation system was configured to provide 100% exhaust to the area. Oxygen levels were close to normal within 20 minutes. The Simplex Fire Detection and Alarm System had been experiencing communication/network malfunctions prior to the release, resulting in the Emergency Voice Evacuation System not being operable; it may have indirectly caused the Halon release. Further investigation is still necessary. A failure of a power supply for the Warehouse portion of the system may have caused the system-wide Simplex issues. Once the power supply was restored and the system re-booted all systems returned to normal. Until confidence can be gained in the system stability, other gas-based suppression systems were temporarily locked out. Page 4 Smoldering caused by lithium reaction On August 14, 2012, while a vacuum cleaner was being used to remove ~ 25 gm lithium from one of the Li Droppers in the Lithium Technology Development Laboratory, a Lithium/air reaction began occurring in the fire retardant, all-metal vacuum cleaner specifically designed to clean fireplace ash. This vacuum cleaner had been approved by PPPL ESH and has been used in similar previous cleanups, though the amount of Li was approximately half as much. PPPL ESH personnel were already at the location since that had been a planned precautionary measure for the evolution. After five minutes of vacuuming, some smoke and an acrid odor were released from the vacuum so the applicable portions of the building were evacuated. The vacuum cleaner was removed from the building and was eventually placed in a 30 gallon drum for temporary storage in the Hazmat Building. The building was ventilated using forced air and negative pressure from the C-Site MG building exhaust fans. After the odor was removed from the building, personnel were allowed to return to their work areas. The vacuum cleaner contained the reaction and no injuries occurred. The lithium being handled was expected to be “passivated” lithium powder which is not pyrophoric, but this was not the case. The lithium had been used and then allowed to passivate over time (6 weeks) by exposure to air. PPPL has issued a Stop Work order on all work with lithium at PPPL and PPPL is formally chartering a Lithium Safety Committee. 10. Pantex Site Office (PSO) Nothing to report 11. Portsmouth/Paducah Project Office(PPPO) Draft LL in progress: Temporary Recovery Actions and Condition Changes about outside storage of materials in changing weather conditions. 12. Richland (RL) / Hanford Site PRC issued an information bulletin about LL when using ground-penetrating radar (GPR). An excavator uncovered a multi-strand cable despite pre-work use of GPR that did not show the cable. LL is about the limitations of GPR: need to add three feet beyond what is estimated for an underground utilities check, particularly around buildings. In short, consider adding distance. 13. Sandia Site Office (SS) / SNL Ruocco noted the Final Report from July 24, 2012, Lithium Fire and Explosion at Plasma Material Test Facility in Bldg. 6530, NA--SS-SNL-1000-2011-0007 On August 26, 2011, at the Plasma Materials Test Facility, part of a test assembly containing liquid lithium in the EB1200 vacuum chamber appears to have failed, which resulted in a small flash fire and explosion. The initial conclusion is that lithium was released into the chamber when the part failed. Some of this lithium went into a beam line that extends from the vacuum chamber and a second failure occurred in a cooled ceramic sleeve in the beam line. This second failure released coolant (water and propylene glycol) that reacted with the lithium and likely released hydrogen, as well as oxygen, resulting in the explosion. An overpressure rupture disk on the chamber operated as designed, but the pressure release was not sufficient to prevent the failure of a welded seam in a 22-inch tube connecting the beam line to the vacuum vessel. Three individuals in the vicinity of the vacuum vessel reported some degree Page 5 of ringing in their ears, but a total of four individuals were sent to Medical for evaluation. The pressure from the explosion damaged the vacuum chamber and a panel of riveted wall siding and an exterior door. The facility was put in a secured state prior to departure for the day. On August 27, a team was assembled to plan re-entry into the building to ensure the facility and vacuum chamber were in a safe state and to prepare the space for access by an independent investigation team, who will investigate the event. An extent of condition was conducted. The failure of the component was anticipated. However, the manner in which the component failed and the contact of the liquid lithium with other materials inside the vacuum chamber was not sufficiently considered or evaluated. The escaping liquid lithium contacted surfaces that failed due to the reactive nature of molten lithium. The surface failure of the cooling line resulted in the fire/explosion. Personnel in the area heard and felt the impact of the explosion with temporary symptoms such as ringing in the ears. 14. Savannah River (SR)/ SRSO Nothing to report 15. Stanford Site Office (SSO) Nothing to report 16. Thomas Jefferson Site Office Nothing to report 17. YSO/Y-12 Nothing to report LESSONS LEARNED GUIDANCE DISCUSSION Guidance for writing effective Lessons Learned for submission to the DOE Lessons Learned program is available on the Operating Experience Committee Wiki http://operatingexperience.doehss.wikispaces.net/OEC+Home Go to the Helpful Products section for Attributes of a Good Lessons Learned. Camille Robison, INL/AMWTP, offered to provide the Advanced Mixed Waste Treatment Project document, Operating Experience/Lessons Learned, MP-ISIH-2.43. Contact her at Camille.Robison@amwtp.inl.gov EXTERNAL ORGANIZATIONS OPERATING EXPERIENCE AND LESSONS LEARNED DISCUSSION Nothing to report. UPDATE ON OFFICE OF ANALYSIS AND CORPORATE OPERATING EXPERIENCE INITIATIVES Page 6 - ORPS Order and OE Order implementation- Ruocco EFCOG’s ORPS Task Group and HSS continue to work on DOE O 232.2, Occurrence Reporting and Processing of Operations Information, interpretation issues. The next ORPS Task Group conference call is August 22nd. OE Videos of the Week- the latest video posted was “Electric Vehicle Safety Training” from the National Fire Prevention Association and National Electrical Contractors Association. Please send any OE relevant videos that you would like to see on the OE Wiki to Ruocco. - Lessons Learned Program and Database- Ruocco Ruocco discussed the use of Lessons Learned Reports versus ORPS Reports. ORPS Reports are not the same as Lessons Learned Reports. ORPS Reports follow DOE O 232.2 requirements where the basic ‘who, what when, where how’ questions of the event are answered. Lessons Learned reports are not a copy/paste of an ORPS report. Lessons Learned reports share a good work practice or innovative approach that is shared to promote the application or prevent recurrence of an adverse work practice or experience. Lesson Learned reports provide specific lessons learned and discussion that may be a result of an ORPS reportable event. - Corporate OE documents under development or recently released- Ruocco OE Summary Article, Operating Experience from Cerro Grande and Los Conchas Fires Improves Los Alamos National Laboratory Emergency Preparedness and Response to Wildfire Events Draft OE-3, Lack of Familiarity with Infrequently-Operated Vehicles Puts Drivers in Danger Draft OE-3, Equipment Presents Crushing Dangers Draft OE-3, Criticality Safety Draft OE-3, Dangers of Respirable Silica Draft OE-3 or OES, Central and Eastern United States Seismic Source Characterization Draft OE-3 or OES, Use of Alternative Asbestos Control Methods in Demolition Activities Draft OE Summary Article, Department of Energy and Pacific Northwest National Laboratory Collaborate to Deploy More Effective Readiness Process Draft OE Summary Article, Chemical Spill Prevention Draft OE Summary Article, Mower Fatality at the Bryan Mound Site - Self-Assessment reviews on the effectiveness of the OE Program- Ruocco HS-24 drafting a self-assessment of the OE Program, Ruocco summarized the requirements and responsibilities of DOE O 210.2A and how HS-24 is meeting them, improvements made, and improvements needed. Feedback from the OEC is important in improving this Program. Please continue providing all feedback on improvements to the OE Program to Ruocco. Page 7 FALL OPERATING EXPERIENCE COMMITTEE MEETING Discussion of and request for information about fall meeting of the ORPS and OE Committees. ROUNDTABLE Action- Guest Speaker Volunteers requested. If you would like to present to the OEC, please call Ashley to volunteer. Thank you in advance! The September 2012 Conference Call is scheduled for Tuesday, September 11. Call-In #: 301-903-7073, Confirmation #: 390575 (70 lines maximum). Roll Call via Email: Attendees are asked to e-mail their name, company name or government organization, and phone number to Gail Thomason, gthomason@pec1.net, at the beginning of the conference call. Ashley Ruocco, DOE HS-24, E-Mail: Ashley.Ruocco@hq.doe.gov. Phone number: (301) 903-7010. Operating Experience Websites: OE Documents (HSS) - http://www.hss.doe.gov/SESA/Analysis/oel.html OE Summaries (HSS) - http://www.hss.doe.gov/sesa/Analysis/oesummary/index.html OE Wiki - http://operatingexperience.doe-hss.wikispaces.net/ OES Blog - http://oesummary.wordpress.com/ Page 8