Safety Culture - Operating Experience

advertisement

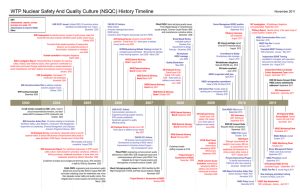

Safety Culture Jim Hutton December 3, 2013 1 Safety Culture at DOE Organizational Culture • A set of commonly shared beliefs, expectations, Organizational Culture and values that influence and guide the thinking and behavior of organization members, and are reflected in how work is carried out. Safety Culture • An organization’s values and behaviors modeled Safety Culture by its leaders and internalized by its members, which serve to make safe performance of work the overriding priority to protect the workers, SCWE the public, and the environment. Safety Conscious Work Environment Safety Conscious • A work environment in which employees feel Work free to raise safety concerns to management (or Environment a regulator) without fear of retaliation. 2 Safety Culture at DOE • Overview of Activities Completed • Training Feedback • Major Activities in Progress • Major Activities in 2014 • Summary 3 Activities Completed 2011 Sept • DOE G 450.4-1C, DOE Integrated Safety Management System Guide issued DOE definition of Safety Culture − Safety Culture focus areas, attributes, behaviors − Dec 2012 Jan Mar Apr S-1 issued expectations for establishing a positive safety culture and a Safety Conscious Work Environment (SCWE) • HSS issued the independent assessment of Safety Culture at WTP • WTP Project Execution Plan revised to clarify roles and responsibilities • HSS assessment of Hanford ECP • 4 Activities Completed (cont.) 2012 May • • June • July • • Both ORP and contractor developed Safety Culture Improvement Plans in response to the HSS Independent Assessment Hanford ECP assistance visit S-1 conducted Town Hall meeting at WTP, reiterating his expectations WTP contract Performance Evaluation and Measurement Plan and performance measures changed to reflect Safety Culture expectations and “balanced priorities” Delivered the SAF-200 DOE/DOE Contractor Senior Leader SCWE training pilot session 5 Activities Completed (cont.) 2012 July Aug Sep Oct Issued SCWE self-assessment guidance consistent with DOE G 450.4-1C • Revised/improved SAF-200 course materials • Deployed SAF-200 instructors to begin courses across the DOE complex • DOE issued addendum to the 2011-1 IP • Identified additional training requirements for SCWE across the DOE complex • First Line Supervisor course − Employee module − 6 Activities Completed (cont.) 2013 Feb • HSS Independent Assessment reports issued: − − − − − − − March • WTP Chemistry and Metallurgy Research Building Replacement (CMRR) – Los Alamos Uranium Processing Facility – Y-12 EM Headquarters Sodium Bearing Waste Treatment Facility Pantex Salt Waste Processing Facility HSS Headquarters assessment 7 Activities Completed (cont.) 2013 May • ORP and BNI action effectiveness review • S-1 town hall at Headquarters Jun • S-1 town hall at Hanford July • NNSA Federal staff assessment Aug • SAF-200 DOE/DOE Contractor Leader and Manager training − 1700 trained in 70 sessions (Pilot, HQ, Hanford, SR, Pantex/Y-12, NV, OR, ID, Los Alamos, Paducah, WIPP, Sandia/Albuquerque, Portsmouth, Chicago/Argonne/Fermi) 8 Training Feedback • Quantitative SAF 200 Participant Feedback All classes reported an increase in participant knowledge (aggregate > 20%) − Overall satisfaction rating of 87% − • Qualitative SAF 200 Participant Feedback Outstanding instruction & materials − Appreciation for consistency in presentation of materials across the DOE complex − Course tools and resources able to be immediately applied − 9 Training Feedback (cont.) “It’s not just about safety, this is about leadership.” “I got so much more than I expected. I did not expect to come away with the tools and new perspective. Honestly, I thought it would be a ‘do better’ review of ISMS/Safety. This training really improved my understanding of SCWE and importance of relationships in maintaining a SCWE. It gives me something to use to measure where I am and where I need to improve.” 10 Major Activities in Progress • Senior leader SCWE training – continuing • First line supervisor SCWE course development • WTP Safety Culture Progress Review meetings • Benchmarking best practices • Review of SCWE self assessments and extent of condition reports 11 Major Activities 2014 • • • Consolidated report on SCWE extent of condition reviews Development of safety culture sustainment actions Implementation of safety culture sustainment actions 12 Summary • • • • Changing the culture is a journey Significant effort continues Anecdotal evidence of progress Much more to do! 13