Intensified Protein Structure: shear cell development The Institute for

advertisement

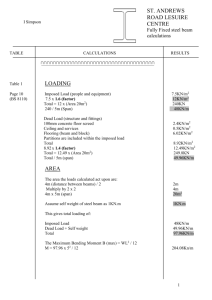

Intensified Protein Structure: shear cell development The Institute for Sustainable Process Technology (ISPT) has initiated a partnership between Wageningen University (WUR) and TU Delft, represented by the Intensified Reaction & Separation Systems group in the Department of Process & Energy at the Faculty of Mechanical, Maritime and Materials Engineering. The Food Structuring group at WUR studies vegetable-based products with a high protein content (2030 per cent), as a substitute for such foods as cheese and meat. Research has shown that consuming these can deliver substantial health benefits. Moreover, the production of meat drains natural resources. In the near future it is expected that a need will emerge to manufacture high-protein foods in a more responsible, healthier and “smarter” way. Meat substitutes are already available, but it seems that they do not always satisfy consumer wishes. The challenge is to produce a vegetablebased product which better approximates our “taste experience” of meat, so that we can move towards a more sustainable vegetarian society. At present, WUR’s work in this field is relatively small in scale. The partnership with TU Delft, in a project entitled Intensified Protein Structure, is intended to expand it. The first stage is the development of a semi-batch process, as a stepping stone towards a continuous one. The design of the proposed production cell, known as a shear cell, is based upon the Taylor-Couette flow principle. A test cell is already operational, capable of processing about 150ml of material at a time. The new cell should increase that figure to 6 litres. Structuring vegetable-based proteins is best done at a raised temperature of approximately 150°C. The transition from a viscous substance to a more solid fibrous structure is brought about by differences in the shear force acting upon the material in cross-section. The shear is measured by a rheometer, which is attached to a drum rotating at about 50rpm inside a fixed external housing. DEMO is supporting the current testing phase, the complete new design and the preparation, assembly and installation of the entire system. For more information, please contact Jeroen Koning: tel. +31 15 278 7779; e-mail j.r.a.koning@tudelft.nl

![List of changes: 1- Page2: reference “[22]” is added to the end of this](http://s3.studylib.net/store/data/007188902_1-dc3ffc6bfa98d4af9207cb70e1033027-300x300.png)