Shear Stress - GLLM Moodle 2

advertisement

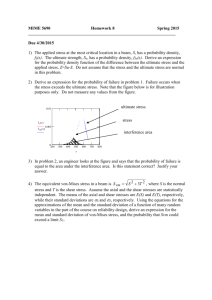

BTEC Nationals Mechanical Principles and Applications Static Loading of Systems Shear Stress and Strain Coleg Llandrillo Cymru Page 1 17/02/2016 Shear Stress Shear force is a force applied sideways onto the material (transverse loading). This occurs typically: Shearing Punching Transverse Force Shear Pin Shear stress is the force per unit area resisting the load. This means the cross sectional area of the work being cut, the beam and the pin respectively. Shear stress τ = F/A. The symbol τ is called Tau and the area is the area being sheared. As with direct stress, we may define a safety factor as the ratio of the fail shear stress to the actual working stress. The sign convention for Shear Force and Stress is based on how it shears the materials and this is shown below. Coleg Llandrillo Cymru Page 2 17/02/2016 Shear Strain Ɣ The symbol Ɣ is called Gamma. In order to understand the basic theory of shearing, consider a block of material being deformed sideways as shown. (Note in reality the deformation is very small and the diagram is much exaggerated). The shear force causes the material to deform as shown. The shear strain is defined as the ration of the distance deformed to the height, x/L. The end face rotates through an angle Ɣ. (N. B. Ɣ must be measured in radians). Since this is a very small angle, it is accurate to say that the distance x is the length of an arc of radius L and angle Ɣ, so that x = LƔ. As support to that statement. x = LsinƔ But sinƔ ≈ Ɣ for very small angles, if Ɣ is measured in radians. So x = LƔ Transposing to make Ɣ the subject gives… Ɣ = x/L It follows that Ɣ is the Shear Strain. Remember Ɣ is measured in radians. Coleg Llandrillo Cymru Page 3 17/02/2016 Modulus of Rigidity If we were to conduct an experiment and measure x for various values of F, we would find that if the material is elastic, it will behave like a spring and so long as we do not damage the material by using too big a force, the graph of F against x is a straight line as shown. The gradient of the graph is constant so F/x = constant and this is termed the Shear Spring Stiffness of the block in N/m. If we divide Force F by area A and deformation x by height L, the relationship is still a constant, as both A and L are constants, we get F/A ÷ x/L = FL/Ax = constant But F/A = τ and x/L = Ɣ so F/A ÷ x/L = FL/Ax = τ / Ɣ = constant This constant has a special value for each elastic material and is called The Modulus of Rigidity and is given the symbol G. G=τ/Ɣ Ultimate Shear Stress If a material is sheared beyond a certain limit, it becomes permanently distorted and does not spring all the way back to its original shape. The elastic limit has been exceeded. If the material is stressed to such a degree that it parts into two (e.g. a guillotine or punch), the ultimate limit has been reached. The Ultimate Shear Stress is τu and this value is used to calculate the force needed by shears and punches. Coleg Llandrillo Cymru Page 4 17/02/2016 Worked Example No. 1 Calculate the force needed to guillotine a piece of metal 3.2mm thick and 1.2m wide given that the ultimate shear stress is 50MPa. Solution The area of the rectangle to be cut is 0.0032m x 1.2m A = 0.0032 x 1.2 A = 0.003 84m2 τ = F/A so F = τA = 50 x 106 x 0.003 84 = 192 000N F = 192kN Worked Example No. 2 Calculate the force needed to punch a hole 35mm diameter in a sheet of metal 2.5mm thick given that the ultimate shear stress is 60MPa. Solution The area to be sheared is the circumference x thickness A = πd x t = π x 0.035 x 0.0025 A = 275 x 10-6m2 τ =F/A so F = τA = 60 x 106 x 275 x 10-6 = 16493N F = 16.5kN Worked Example No. 3 Calculate the force needed to shear a pin 6mm diameter given that the ultimate shear stress is 60MPa. Solution The area to be sheared is the cross sectional area. A = πR2 = π x 0.000009 -6 A = 28.3 x 10 m2 F = τA = 60 x 106 x 28.3 x 10-6 = 1696N F = 1.7kN Coleg Llandrillo Cymru Page 5 17/02/2016 Self Assessment Exercise No. 1 1. A guillotine must shear a sheet of metal 0.7m wide and 4mm thick. The ultimate shear stress is 45MPa. Calculate the force required. (126kN) 2. A punch must cut a hole of 25mm diameter in a sheet of steel 1,6mm thick. Calculate the force required if the ultimate shear stress of the material is 60MPa. (7.539kN) 3. Two strips of metal with an ultimate shear stress of 55MPa are pinned together as shown, with a rod of 8mm diameter. Determine the force required to break the pin (2.764kN) 4. A 2.5 Tonne press is to be used for punching holes in a 3mm sheet of material. Calculate whether a 35mm diameter hole can be punched in material has an ultimate shear stress of 75 MPa or not. ( No solution has been given!) Coleg Llandrillo Cymru Page 6 17/02/2016 Double Shear Consider a pin joint with a support on both ends as shown. This is called a CLEVIS and CLEVIS PIN. If the pin shears, it will do so as shown. By balancing the forces it can be determined that the force in the supports is F/2 each. The area sheared is twice the cross section of the pin, so it takes twice as much force to break the pin as for a case of single shear. Double shear arrangements doubles the maximum force allowed in the pin. Worked Example No. 4 A pin is used as a clevis in a supporting tie. The force in the tie will be a maximum of 70kN and the ultimate shear stress allowed in the pin is 100MPa. Calculate the minimum pin diameter necessary in order to achieve a Safety Factor of 4. Solution The Working Stress = 100/4 τ = 25MPa The pin is in Double Shear so τ = F/2A so But A = F/2τ = 70 x 103/ (2 x 25 x 106) A = 0.0014m2 A = πD2/4 D = √(4A/π) = √(4 x 0.0014/π) = √0.00178 D = 0.043m (NOTE: - This has been rounded UP) Coleg Llandrillo Cymru Page 7 17/02/2016 Self Assessment Exercise No. 2 1. A clevis pin is used to join two steel rods in a structure as shown. The pin is 10mm in diameter and the material from which it is made has an ultimate shear stress of 70MPa. Determine the maximum force that can be exerted when a Safety Factor of 2 is used. (5.5kN) 2. A Shear pin, loaded in double shear, is required to break at a force of 3.5kN. If the material has an ultimate Shear Stress of 90MPa, calculate the required diameter of the pin. (5mm) Coleg Llandrillo Cymru Page 8 17/02/2016