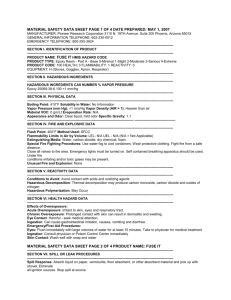

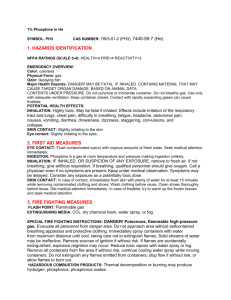

section 1 * chemical product and company identification

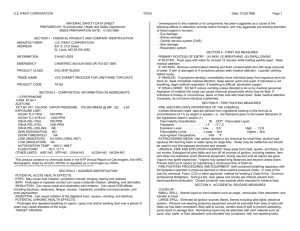

advertisement

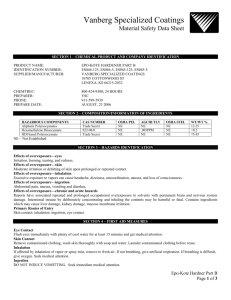

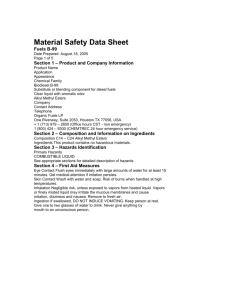

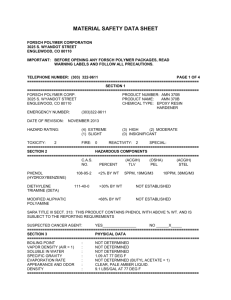

Vanberg Specialized Coatings Material Safety Data Sheet SECTION 1 – CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME: IDENTIFICATION NUMBER: SUPPLIER/MANUFACTURER: ARMORCOAT CR HARDENER PART B 92600, 92600-15, 92600G, 92600G-15 VANBERG SPECIALIZED COATINGS 10705 COTTONWOOD ST LENEXA, KS 66215-2032 CHEMTREC: PREPARER: PHONE: PREPARE DATE: 800-424-9300; 24 HOURS VSC 913-599-5939 SEPTEMBER, 4 2012 SECTION 2 – COMPOSITION/INFORMATION OF INGREDIENTS CHEMICAL NAME CAS NUMBER OSHA PEL AGCIH TLV OSHA STEL Benzyl Alcohol Trimethylhexanediamine Isophoronediamine Triethylene Tetramine 100-51-6 3236-53-1 2855-13-2 112-24-3 NE NE NE NE NE NE NE NE NE NE NE NE WT/WT % 20-40 1-10 20-40 1-10 *No toxic chemical(s) subject to reporting requirements of section 313 of Title III and of 40 CFR 372. SECTION 3 – HAZARDS IDENTIFICATION Effects of overexposure—eyes Vapors – Can cause irritation and burns to eyes. Effects of overexposure—skin Corrosive – Can cause burns to skin. Effects of overexposure—ingestion Can cause severe damage to mouth and throat. Effects of overexposure—inhalation Vapors – Can cause severe irritation of respiratory tract. Effects of overexposure—chronic and acute hazards Repeated and/or prolonged exposures may result in liver disorders (such as jaundice or liver enlargement), kidney disorders (such as edema or proteinuria), adverse respiratory effects (such as couch, tightness of chest, or shortness of breath), adverse skin effects (such as defatting, rash, irritation, or corrosion), adverse eye effects (such as conjunctivitis or corneal damage). Carcinogenicity: NTP Carcinogen: No IARC Monographs: No OSHA Regulated: No Medical conditions generally aggravated by exposure Skin contact may aggravate existing dermatitis (skin condition). Over exposure to vapor or mist may aggravate existing respiratory conditions such as asthma, bronchitis, or fibrotic respiratory disease. Other Instructions Swallowing this corrosive material may result in severe ulceration, inflamation, and possible perforation of the upper alimentary tract, with hemorrhage and fluid loss. Aspiration of this product during induced emesis can result in severe lung injury. If evacuation of stomach is necessary, use method least likely to cause aspiration, such as gastric lavage after endotracheal intubation. Contact a Poison Control Center for additional treatment information. Armorcoat CR Hardener Part B Page 1 of 4 SECTION 4 – FIRST AID MEASURES Eye Contact Flush eyes with water for at least 15 minutes and consult a physician. DO NOT attempt to neutralize with chemical agents. Skin Contact Flush immediately for 15 minutes with potable water. DO NOT attempt to neutralize with chemical agents. Remove contaminated clothing. Launder before reuse. Discard contaminated shoes. Get medical attention if swelling and/or irritation occurs. Inhalation Remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Consult a physician. Ingestion Give water to dilute stomach contents. DO NOT induce vomiting. If vomiting occurs, give fluids again. Get immediate medical attention. Do not give anything by mouth to an unconscious or convulsing person. Note to physicians: This product is highly injurious to all tissues, similar to that of ammonia or ammonia gas. Chemical pneumonitis, pulmonary edema, laryngeal edema and delayed scarring of the airway or other affected tissues may occur following exposure. There is no specific treatment. Clinical management is based on supportive treatment, which is similar to that for thermal burns. SECTION 5 – FIRE FIGHTING MEASURES Flash Point >200º F Method used Closed cup Flammable Limits In Air By Volume Lower: Not determined. Upper: Not determined. Extinguishing Media Foam, CO 2, dry chemical Special Fire fighting Procedures Wear positive pressure self-contained breathing apparatus. Use water to cool containers exposed to fire. Water runoff can cause environmental damage. Dike and collect water used to fight fire. Unusual Fire and Explosion Hazards Toxic fumes present when this material involved in fire. Containers may rupture. SECTION 6 – ACCIDENTAL RELEASE MEASURES Spill or Leak Procedures Flush area with water spray. Absorb spill with inert material (e.g. dry sand or earth), then place in a chemical waste container. Avoid runoff into storm sewers and ditches which lead to waterways. Wear a self-contained breathing apparatus and appropriate personal protective equipment. SECTION 7 – HANDLING AND STORAGE Handling Avoid contact. Allow only personnel wearing goggles, neoprene or rubber gloves and protective clothing to clean up spill. In confined areas a full face respirator is recommended. Absorb spill with clay, diatomaceous earth or other absorbent material. Place in disposal containers. Handle in well-ventilated workspace. Empty containers may contain explosives vapors. Wash thoroughly after handling. Avoid contact with skin, eyes, and clothing. Storage Keep container closed when not in use. Keep container in a cool, well-ventilated place. Keep away from food, drink, and animal feeding stuffs. Store away from ignition sources. Ground all containers during transfer. Keep away from oxidizers, heat, or flames. Precautions Avoid contact. Keep containers tightly closed when not in use. Do not remove labels from empty containers. If mixtures of Part B and Part A are allowed to remain in the mixing container past the pot life deadline, heat and a strong reaction will result. Armorcoat CR Hardener Part B Page 2 of 4 SECTION 8 – EXPOSURE CONTROLS/PERSONAL PROTECTION Engineering Controls Good general ventilation should be sufficient to control airborne levels. Local exhaust ventilation may be necessary to control any air contaminants to within their TLVs during the use of this product. Facilities storing or utilizing this material should be equipped with an eyewash facility and a safety shower. Respiratory Protection In poorly ventilated areas where occupational exposure limit is exceeded, us appropriate NIOSH/MSHA approved self contained breathing equipment or a full face respirator Skin Protection Where contact is likely, wear chemical resistant gloves, rubber boots, and chemical safety goggles. Eye Protection Wear chemical safety glasses with side shields or goggles. In emergency situations, use eye goggles with a full face shield. Other Protective Equipment Nitrile rubber gloves Hygienic Practices Wash hands before eating. Remove contaminated clothing and wash before reuse. Use only in a well-ventilated area. Avoid contact with eyes, skin, and clothing. SECTION 9 – PHYSICAL AND CHEMICAL PROPERTIES Boiling Range 414º F Vapor Density NE Vapor Pressure NE VOC 0.00 Solubility in Water <1% @ 77º F Appearance & Odor Amber low viscosity liquid with sharp ammonia odor Specific Gravity (H20=1) 0.99 Evaporation Rate NE SECTION 10 – STABILITY AND REACTIVITY Chemical Stability This product is stable under normal storage conditions. Stability Conditions to Avoid Contact with acids such as hydrochloric or sulfuric. Hazardous Decomposition or By-Products When exposed to fire, oxides of Carbon and Nitrogen will be generated. Irritating and toxic fumes at elevated temperatures Hazardous Polymerization Will not occur under normal conditions Incompatibilities (materials to avoid) Avoid strong oxidizing agents and epoxy resins under uncontrolled conditions. SECTION 11 – HMIS RATINGS Health Flammability Reactivity Personal 3 1 0 C Armorcoat CR Hardener Part B Page 3 of 4 SECTION 12 – ECOLOGICAL INFORMATION Exotoxicity Exposure at low concentrations may kill fish Environmental Fate No information SECTION 13 – DISPOSAL CONSIDERATIONS Comply with all Federal, State and Local Regulations. Incinerate in admixture with fuel equipped with a scrubber to remove nitrogen oxides and carbon monoxide. Dispose of in a permitted waste management facility if incineration or landfill is not practicable. SECTION 14 – TRANPORTATION INFORMATION DOT Proper Shipping Name: DOT Technical Name: DOT Hazard Class: DOT UN/NA Number: Packing Group: RQ (Reportable Quantity): CAUSTIC ALKALI LIQUID NOS MODIFIED CYCLOALIPHATIC AMINES 8 UN1719 II N/A SECTION 15 – REGULATORY INFORMATION SECTION 16 – OTHER INFORMATION The information accumulated herein is believed to be accurate but is not warranted to be whether originating with the company or not. Recipients are advised to confirm in advance of need that the information is current, applicable, and suitable to their circumstances. Armorcoat CR Hardener Part B Page 4 of 4