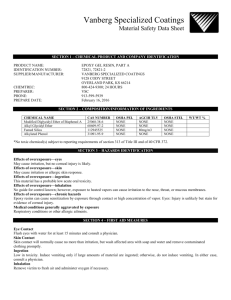

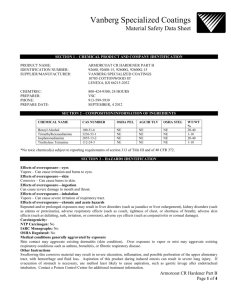

section 1 – chemical product and company identification

Vanberg Specialized Coatings

Material Safety Data Sheet

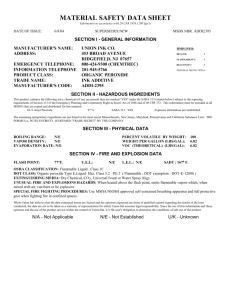

SECTION 1 – CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NAME:

IDENTIFICATION NUMBER:

SUPPLIER/MANUFACTURER:

EPOXY GEL HARDENER, PART B

72821, 72821-2

VANBERG SPECIALIZED COATINGS

CHEMTREC:

PREPARER:

9128 CODY STREET

OVERLAND PARK, KS 66214

800-424-9300; 24 HOURS

VSC

PHONE:

PREPARE DATE:

913-599-5939

April 17, 2020

SECTION 2 – COMPOSITION/INFORMATION OF INGREDIENTS

CHEMICAL NAME

Nonyl Phenol

CAS NUMBER

25154-52-3

N-Aminoethylpiperazine 140-31-8

Fumed Silica 112945525

Alkylated Phenol 31091-95-9

OSHA PEL AGCIH TLV OSHA STEL WT/WT %

NONE NONE NONE

NONE

NONE

NONE

NONE

80mg/m3

NONE

NONE

NONE

NONE

*No toxic chemical(s) subject to the reporting requirements of section 313 of Title III and of 40 CFR 372 are present.

SECTION 3 – HAZARDS IDENTIFICATION

Effects of overexposure—eyes

Will cause burns to the eyes. High vapor concentrations can cause severe irritation to the eyes.

Effects of overexposure—skin

Will cause burns to the skin.

Effects of overexposure—ingestion

Liquid can cause severe damage to mucous membranes if swallowed.

Effects of overexposure—inhalation

High concentrations of vapor can cause irritation to the respiratory tract, nausea, and dizziness.

Effects of overexposure—chronic hazards

Prolonged or repeated exposure may cause asthma and skin sensitization or other allergic responses.

Medical conditions generally aggravated by exposure

Respiratory conditions and other allergic responses.

SECTION 4 – FIRST AID MEASURES

Eye Contact

Immediately flush with large amounts of water for at least 15 minutes while lifting upper and lower lids. Get immediate medical assistance.

Skin Contact

Flush skin with water for at least 15 minutes and remove all contaminated clothing immediately. Get medical attention if reddening or swelling occurs.

Inhalation

Remove to fresh air if effects persist and administer oxygen if necessary.

Ingestion

Do not induce vomiting. Dilute by giving water or milk to drink if victim is conscious. Get medical attention immediately.

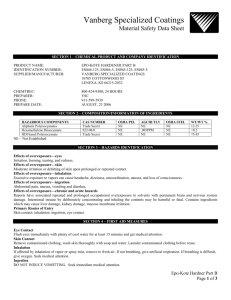

SECTION 5 – FIRE FIGHTING MEASURES

Flash Point

200+ºF (seta flash)

Flammable Limits

Not applicable.

Extinguishing Media

Foam, alcohol foam, CO2, dry chemicals, water fog

Special Fire fighting Procedures

Toxic fumes will be evolved when this material is involved in a fire. A self-contained breathing apparatus should be available for firefighting. Cool fire exposed containers with water.

Unusual Fire and Explosion Hazards

None known.

SECTION 6 – ACCIDENTAL RELEASE MEASURES

Spill or Leak Procedures

Avoid contact with material. Wear the appropriate safety equipment. Stop spill at source, dyke area to prevent spreading. Pump liquid to salvage tank. Take up remainder with clay or other absorbent and place in disposal containers.

SECTION 7 – HANDLING AND STORAGE

Precautions

Avoid all skin contact. Avoid breathing vapors. Reseal partially-used containers. Properly label all containers. Wash with soap and water before eating, drinking, smoking, or using toilet facilities. Observe conditions of good industrial hygiene and safe working practices.

Other Precautions

Mixed materials contain the hazards of all the components; therefore, read the MSDS of all components to become familiar with all hazards prior to using this product.

SECTION 8 – EXPOSURE CONTROLS/PERSONAL PROTECTION

Eye Protection

Wear splash-proof goggles or safety glasses with side shields.

Protective Gloves

Impervious gloves; neoprene or rubber

Respiratory Protection

NIOSH-approved respirator protection is required in the absence of proper environmental controls. For emergencies, a self-contained breathing apparatus or a full face respirator is recommended.

Ventilation

Avoid breathing vapors. Ventilation must be sufficient to control vapors.

Other Protective Clothing or Equipment

Clean body covering clothing as well as apron footwear or other equipment should be used as deemed necessary to avoid contact with the material.

Wash Requirements

Observe general good hygienic practices.

SECTION 9 – PHYSICAL AND CHEMICAL PROPERTIES

Appearance and Odor:

Vapor Density:

Boiling Range:

Amber viscous paste with amine odor

Not applicable

560ºF

Evaporation Rate:

Specific Gravity:

Solubility in Water:

Not applicable

1.1

Negligible

SECTION 10 – STABILITY AND REACTIVITY

Chemical Stability

This product is stable under normal storage conditions.

Stability Conditions to Avoid

Avoid contact with open flames and all sources of ignitions and sparks.

Hazardous Decomposition Products

CO, CO2, NOX

Hazardous Polymerization

Will not occur

Incompatibilities

Avoid contact with strong oxidizing agents, mineral acids, and epoxy resins in uncontrolled amounts.

SECTION 11 – HMIS RATINGS

Health:

Flammability:

Reactivity:

2

1

0

SECTION 12 – ECOLOGICAL INFORMATION

Environmental Fate

No information found.

Environmental Toxicity

No information found.

SECTION 13 – DISPOSAL CONSIDERATIONS

Dispose of in accordance with appropriate federal, state, and local regulations.

SECTION 14 – TRANPORTATION INFORMATION

DOT Shipping Name:

DOT Hazard Class:

RQ (Reportable Quantity):

No information.

Not applicable.

Not applicable.

SECTION 16 – OTHER INFORMATION

The information accumulated herein is believed to be accurate but is not warranted to be whether originating with the company or not.

Recipients are advised to confirm in advance of need that the information is current, applicable, and suitable to their circumstances.