Chillers

advertisement

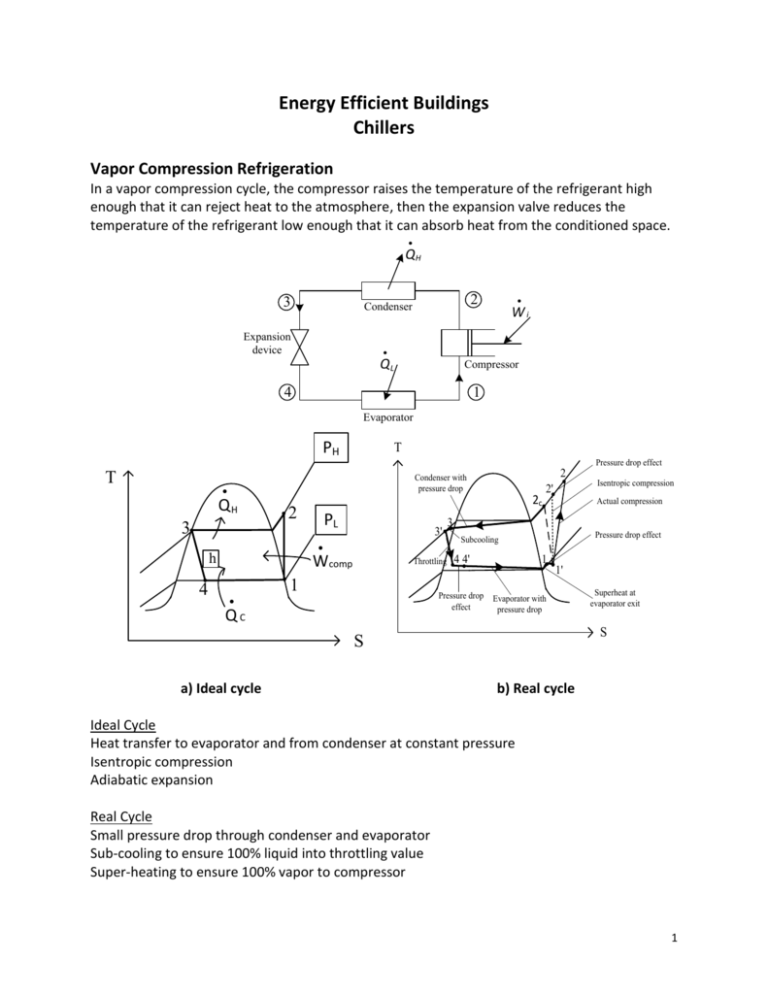

Energy Efficient Buildings Chillers Vapor Compression Refrigeration In a vapor compression cycle, the compressor raises the temperature of the refrigerant high enough that it can reject heat to the atmosphere, then the expansion valve reduces the temperature of the refrigerant low enough that it can absorb heat from the conditioned space. QH 3 2 Condenser Expansion device Wi QL Compressor 4 1 Evaporator PH T Pressure drop effect T QH 3 2c 2 PL 3' h 4 2 Condenser with pressure drop Wcomp Throttling 1 Actual compression 3 Pressure drop effect Subcooling 4 4' Pressure drop effect QC Isentropic compression 2' 1 1' Evaporator with pressure drop S S a) Ideal cycle Superheat at evaporator exit b) Real cycle Ideal Cycle Heat transfer to evaporator and from condenser at constant pressure Isentropic compression Adiabatic expansion Real Cycle Small pressure drop through condenser and evaporator Sub-cooling to ensure 100% liquid into throttling value Super-heating to ensure 100% vapor to compressor 1 Irreversibilities during compression increase entropy, but heat loss from compressor reduces entropy. Compressors Compressors are important since Win = Wcomp. Compressing vapor requires more work than compressing liquid since: dw = v dP and vliquid << vvapor Reciprocating Compressors Small (.1 to 50 tons) Noisy Turn on when compressing and completely off when idle Often multiple reciprocating compressors staged on/off to meet loads. Results in high part-load efficiency Screw Compressors Mid-sized (50-300 tons) Quiet Compress by squishing vapor between screws At part-load, vapor flow reduced, but screw keeps rotating. Thus, poor part-load efficiency unless motor slowed with VSD Centrifugal Compressors Large (300 tons +) Vapor compressed as spun to outside Like screw compressors, don’t stop impellor at part-load. Thus poor part-load efficiency unless motor slowed by VSD. Most centrifugal compressors are integrated into chiller with tube and shell heat exchangers for condenser and evaporator. Evaporators An evaporator is a heat exchanger that absorbs heat from the conditioned space. While absorbing heat, the refrigerant “evaporates” from liquid to vapor. An expansion value at exit of evaporator pushes vapor to super heat region prior to entrance into the compressor. The two primary types of evaporators are: Refrigerant–to–Air Finned tube HX, Fins on air side since hair<<href Used in small to medium chillers “Direct Expansion”, “DX” since refrigerant directly cools air as it expands 2 Refrigerant–to–Water Tube-in-shell HX Ref in shell, water in tubes Used in large centrifugal chillers “Chilled” water pumped from evap to air handling unit chilled water coils Condensers A condenser is a heat exchange that rejects heat from building and compressor to the environment. While rejecting heat, the refrigerant “condenses” from vapor to liquid. The total heat rejected by the condenser is the sum of the heat from the building and the work added to the compressor. Qcondenser = Qevaporator + Wcompressor The two types of condensers are: Refrigerant-to-Air Finned tube HX, with fins on air side Called “Air Cooled” Tcondenser = Tair Small to med chillers Refrigerant-to-Water Tube in shell with vapor on shell side Condenser water cooled in cooling tower Tcondenser water < Tair, due to evaporation Colder condenser temperature increases efficiency Increased efficiency is worth price of cooling towers in big chillers Efficiency and Temperature Chiller efficiency is a function of the temperatures that it absorbs heat from and rejects heat to. An energy balance on a chiller shows that compressor work is the difference between the heat rejected by the condenser and the heat absorbed by the evaporator. Wcomp = Qcond – Qevap Because dQ = T dS, on a TS diagram, the heat rejected by the condenser is the area under the condenser line. The heat absorbed by the evaporator, Qevap, is the area under the evaporator line. The compressor work, Wcomp, is the area below the condenser line and above the evaporator line. The efficiency is the ratio of energy absorbed by the evaporator to the work required by the compressor. 3 PH T PH T PL PH PL PL S a) base case T S b) lower evap temperature S c)higher cond temperature To remove heat from cold reservoirs, the evaporator temperature must be less than the reservoir temperature. Thus, removing heat from cold reservoirs requires a lower evaporator temperature. As the evaporator temperature declines, the cooling capacity (Qevap) declines and the compressor work increases. Thus, the efficiency of a chiller declines when it must absorb heat from a lower temperature reservoir. To reject heat to the environment, the condenser temperature must be higher than the environment. Thus, rejecting heat to a warmer environment requires a higher condenser temperature. As the condenser temperature increases, the compressor work increases. Thus, the efficiency of a chiller declines when it rejects heat to a higher temperature reservoir. These concepts can be quantified by considering the following system. Heat naturally flows from high to low temperature reservoirs. Chillers move heat from a low temperature reservoir to a high temperature reservoir, requiring external work. Efficiency is the ratio of useful output to required input. TENV Q cond Wcomp Q evap TROOM Actual Efficiency Efficiency = Qevap / Wcomp Efficiency = Qevap / (Qcond – Qevap) Efficiency ~ 3.0 4 Ideal (Carnot) Efficiency Efficiency = Qevap / Wcomp From an energy balance: Wcomp = Qcond - Qevap Thus, Efficiency = Qevap / (Qcond – Qevap) dQ = T dS Thus, Efficiency = (T dS)evap / ((T dS)cond – (T dS)evap) In an ideal cycle, no turbulence or friction occurs during expansion and compression. Thus, no entropy is produced and (dS)evap = (dS)cond Heat transfer from the condenser to the environment takes place at an infinitely small temperature difference over a very long period of time. Thus Tenv = Tcond and Troom = Tevap And the ideal (Carnot) efficiency is: Ideal Efficiency = Troom / (Tenv – Troom). Example Consider a chiller extracting heat from a room at 70 F and rejecting it to ambient at 90 F. Compare the actual efficiency of a typical chiller of 3.0 to the ideal efficiency. The ideal efficiency is: Ideal Efficiency = (70 + 460)room / ((90+460)env – (70+460)room) = 26 The discrepancy between real and ideal efficiencies indicates lots of irreversibilities and room for improvement. Irreversibilities include: Fast compression Fast expansion Friction (pressure drops) Heat transfer Reducing these irreversibilities are the key design issues for improving chiller performance. 5 Air-Cooled Chillers Air cooled chillers reject heat to the atmosphere by blowing air over a fin-tube heat exchanger through which flows the refrigerant. Air condensers are less expensive and easier to maintain than the cooling towers required by water-cooled chillers. However, the evaporative effect of cooling towers enables water cooled chillers to operate at lower condenser temperatures and pressures, which increases chiller efficiency. Thus, air-cooled chillers are recommended for applications in which low first cost and maintenance costs outweighs the reduced efficiency compared to water cooled chillers. The energy efficiency of air-cooled chillers is rated in terms of Energy Efficiency Ratio (EER). EER is a dimensional measure of efficiency. It is the ratio of the rate of cooling to electrical power consumption by the evaporator and the condenser fans. EER (Btu/Wh) = Qevap (Btu/hr) / (Wcomp + W condfans) (W) @ ARI Std 590-92 conditions The performance of a typical air cooled chiller is shown below. As predicted by a Carnot analysis, efficiency improves when the temperature of air entering the condenser declines or the leaving water temperature increases. Air-Cooled Chiller Evaporator and Condenser Temperature Performance Map LWT °F 20 25 30 35 40 45 50 55 60 Percent Glycol 28 24 19 14 0 0 0 0 0 Tons 11.4 12.9 14.5 16.1 17.9 19.5 21.3 23.1 24.9 75.0 Capacity System KW 15.7 16.1 16.6 17.0 17.5 17.9 18.4 18.9 19.4 EER 8.7 9.6 10.5 11.4 12.3 13.1 13.9 14.7 15.4 Entering Condenser Air Temperature (°F) 95.0 115.0 Capacity System Capacity System Tons KW EER Tons KW 10.2 19.2 6.4 8.8 23.8 11.5 19.7 7.0 10.0 24.4 13.0 20.2 7.7 11.3 24.9 14.5 20.7 8.4 12.6 25.5 16.1 21.2 9.1 14.1 26.1 17.6 21.7 9.7 15.5 26.7 19.2 22.3 10.3 16.9 27.2 20.8 22.8 11.0 18.4 27.9 22.5 23.4 11.6 19.9 28.5 EER 4.4 4.9 5.4 5.9 6.5 7.0 7.5 7.9 8.4 Using the data in the preceding table, the following relation gives chiller EER as a function of leaving water temperature when the condenser air temperature is 75 F. The R2 of the regression is 0.9998. EER = 4.688564 + 0.20999 * LWT -.000518143 * LWT ^ 2 The performance of another air cooled chiller, as functions of outdoor air temperature and part-load ratio is shown below. 6 Chiller Efficiency (kW/ton) 3 2 Outdoor Temperature 35°C 25°C 15°C 1 0 0.2 0.4 0.6 0.8 1 Chiller Part-Load Ratio Air-Cooled Chiller Part-Load and Condenser Temperature Performance Map. Source of data: Chan, K. and Yu, F., 2004, “How Chillers React to Building Loads”, ASHRAE Journal, August, pp 52-58. Water–cooled Chillers The energy efficiency of water-cooled chillers is typically described in terms of specific power: kW/ton = Wcomp / Qevap The nominal kW/ton rating of a chiller is reported at 100% load and ARI standard conditions of 44°F leaving chilled water and 85°F inlet condenser water. Typical nominal kW/ton ratings are shown below. Chiller Reciprocating Screw Centrifugal High Moderate New (kW/ton) .78 to .85 .62 to .75 .50 to .62 .63 to .70 Older (kW/ton) .90-1.2 .75-.85 .70-.80 Chiller efficiency is dependent on the temperature of chilled water leaving the chiller and the temperature of condenser water entering the chiller. For example, chiller efficiency improves 7 by about 1.5%, for every degree F increase in leaving chilled water temperature. This means increasing chilled water supply temperature from 44°F to 54°F can cut chiller power use by about 15%. Similarly, chiller efficiency improves by about 1.5%, for every degree F decrease in entering condenser water. This means decreasing the temperature of entering condenser water from the cooling tower by 10 F, can cut chiller power use by about 15%. In addition, chillers seldom operate at full load since design conditions rarely occur. A performance map for a standard-efficiency constant-speed chiller as a function of entering condenser water temperature and part load is shown below. Standard-Efficiency Water-Cooled Chiller Performance Map A relation for the specific power of this standard-efficiency chiller, KWPT kW/ton, as a function of part load, PL, and condensing water temperature CDWT can be derived from regressing data from the curves shown above. The relation and regression coefficients are shown below. The R2 for this relation is 0.98. KWPT = a + b PL + c PL2 + d CDWT + e CDWT2 + f (CDWT) (PL) a b c d e f 0.57341 -1.2023 0.79481 0.0051964 2.2926 E-05 -0.000805732 A performance map for high-efficiency chillers showing constant speed (red) and variable speed (blue) chiller performance as a function of entering condenser water temperature and is shown 8 below. At equal condenser water temperature, the constant speed chiller uses less kW/ton at full load than the variable speed chiller. However, variable-speed chiller performance improves significantly at part load, and approaches 0.15 kW/ton at some operating conditions. The declining specific power at low loads indicates excellent control efficiency. High-Efficiency Water-Cooled Constant-Speed And Variable-Speed Chiller Performance Map. Source: http://ateam.lbl.gov/cleanroom/doc/Applied_Final.pdf. Lawrence Berkeley National Laboratory, Applications Team. A relation for the specific power, KWPT kW/ton, as a function of part load, PL, and condensing water temperature CDWT for the VSD chiller can be derived from regressing data from the curves shown above. The relation and regression coefficients are shown below. The R2 for this relation is 0.98. KWPT = a + b PL + c PL2 + d PL3 + e CDWT + f CDWT2 a b c d e f -0.18972 -1.4381 2.5595 -1.2500 0.010935 -2.1739 E-05 9 Thermal Storage For most large buildings, the total charge for electricity includes a charge for both the total energy used over a month (kWh) and the peak electrical power during the month (kW). Depending on the particular rate structure, the peak electrical demand charge can be larger than the total energy charge. Thus, electricity costs can be reduced by reducing peak power use (kW) even if total energy use (kWh) remains the same or increases. Moreover, in many large buildings the electrical power use during business hours is much greater than during nighttime and weekend hours. Thus, operating the chiller only during nights and weekends could shift chiller power from peak to off-peak periods and reduce electricity costs. One strategy for shifting chiller use to off-peak periods is to over-cool the building at night and use the buildings thermal mass to offset cooling loads during the day. This strategy requires occupants to accept a temperature rise throughout the day as the building slowly warms up. A second strategy is to use the chillers to create ice during off-peak periods and then use the ice to cool the building during on peak periods. Source: http://energy.gov Absorption Chillers Absorption chillers use heat instead of electricity to produce cooling. The cycle is similar to vapor compression, except that the mechanical compressor is replaced by a generator and absorber. The generator uses heat to raise the pressure and temperature of the refrigerant before rejecting heat in the condenser. 10 Qout Condenser Generator Expansion Valve Thermal Compressor Qin Win Pump Absorber Qout Evaporator Qin The cycle works by using two fluids, a refrigerant and an absorbate. Most cycles use water as the refrigerant and lithium bromite as the absorbate. After leaving the evaporator, the refrigerant vapor is absorbed into the liquid absorbate. The pump raises the pressure of the combined refrigerant/absorbate liquid. The pump uses significantly less energy than a compressor since the pump is raising the pressure of a liquid with small specific volue, while a compressor is raising the pressure of a vapor with large specific volume. w = v dP Heat is added to the generator to evaporate the high pressure refrigerant out of the absorbate. The high pressure refrigerant vapor flows through the condenser to reject heat, and the liquid absorbate is returned to the absorber through a pressure reduction valve. Absorption chillers can have one or two stages of generators and absorbers. The COP of double effect absorption chillers is about 1.0. Absorption chillers may be especially appropriate in applications with available heat or high electrical demand costs. 11