Lecture 4 Refrigerator

advertisement

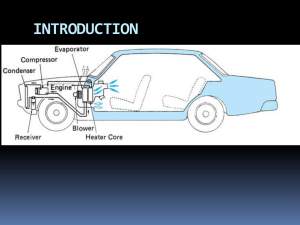

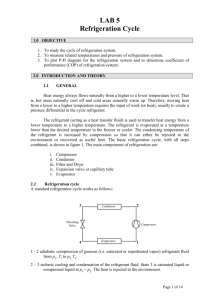

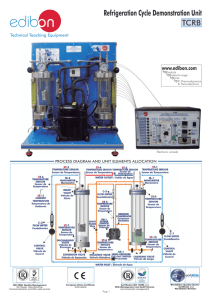

Refrigerators Topics Applications Principles of Operation Diagrams Safety Preventive Maintenance Common Failure Modes Basic Troubleshooting Applications In laboratory or medical setting, used to keep medicines and chemicals cool Principle of Operation Inputs Outputs AC Voltage Heat Absorbing Refrigerant Warm Substances Cooled Substances Principles of Operation Refrigerant cycles through a sealed system of high and low pressures, releasing and absorbing heat Refrigeration: Absorption of heat during the evaporation of a liquid refrigerant Four main components Compressor Condenser Expansion Valve/Metering Device Evaporator Principles of Operation High Temp High Pressure Vapor High Temp High Pressure Liquid Low Temp Low Pressure Vapor Low Temp Low Pressure Liquid Principles of Operation Compressor The refrigerant is compressed into a high pressure, high temperature vapor Condenser As refrigerant passes through the condensing coils heat moves from the refrigerant to the surrounding air causing it to condense. The refrigerant leaves the condenser as a high pressure, high temperature liquid. Principles of Operation Metering Device Regulates how much liquid refrigerant enters the evaporator Tries to maintain a preset temperature difference on either side of the evaporator opening Principles of Operation Evaporator Metering device allows small amount of refrigerant into evaporator Refrigerant rapidly expands, cools At beginning of the evaporator refrigerant is a low pressure, low temperature liquid As refrigerant passes through evaporator, it pulls heat out of refrigerator causing refrigerant to slowly evaporate back into a vapor The refrigerant returns to the compressor as low pressure, low temperature vapor Principles of Operation Electrical Components Compressor Thermostat Overload protector Principles of Operation Compressor Motor and compressor are in one unit and is known as a sealed unit Single phase induction motor Contains two windings Starter (S) Main (M) Principles of Operation Overload Protector A thermal device which opens the circuit of the motor when overloaded Prevents damage to the motor when PTC prevents starting, but current is sent to motor’s main winding Diagrams Expansion Valve Electrical Wire Housing Hot line (outlet) (compressor discharge line) Compressor Drying Assembly Liquid Line Cold Line Power Cord (inlet) (Suction line) Overload Protector Grounding Plate Safety Never puncture any line containing refrigerant Never use a sharp object to chip ice off of evaporator Allow ice to melt naturally or use a hair dryer Use PPE if refrigerator is used to store biological hazards Before using, read the owner's manual Operation Never connect a unit to an overloaded electrical outlet or one with voltage deficiencies Avoid the use of electrical extension cords The electrical outlet must not be more than 2 m from the unit Install the unit on a levelled surface Leave free space around unit to avoid over heating Do not install under direct sun light Preventive Maintenance If connected to good quality electrical circuits and good ventilation flows around the unit, refrigerators function for years without specialized technical maintenance Clean inside of refrigerator box Avoid using steel wool or other abrasive materials for cleaning the shelves and drawers Avoid using gasoline, naphtha or thinners, as these damage the plastic, the packing or the paint on the surfaces. Check door gasket fully seals door Common Failures Blown fuse Bad power connection Evaporator covered in ice Condenser is blocked or dirty Door does not close properly Failed overload protector User Error: improper setup/placement Faulty thermostat Basic Troubleshooting PROBLEM PROBABLE CAUSE The unit is not functioning • • • The freezer is functioning continuously but is not cooling. • The unit is showing fluctuations in temperature. • • • Blown fuse The equipment is disconnected There is no or low electricity in the feed circuit The thermostat is adjusted too high The unit contains excessive frost The temperature control is not calibrated The condenser is dirty PROBLEM PROBABLE CAUSE The unit shows a high temperature • The door is open • Poor door seal • There is a defect in the electrical feed • A warm load (liquids or solids) was placed inside the unit. • The compressor is not functioning • The compressor is functioning but there is no ice in the evaporator Basic Troubleshooting PROBLEM Upon operating the unit, noises similar to clicking sounds can be heard Noisy operation PROBABLE CAUSE • • The compressor’s thermal protector has been disconnected Floor not stable or cabinet not levelled • Drip tray vibrating • The cooling fan is hitting the cover or compressor is loose PROBLEM PROBABLE CAUSE The compressor runs continuously • Not enough air circulation around the unit • Faulty thermostat • Poor door seal • Room too warm • The door is being opened too often or is not closed • The light switch is defective