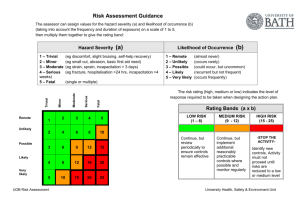

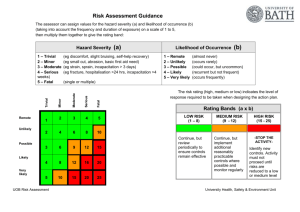

Risk Assessment Guidance

advertisement

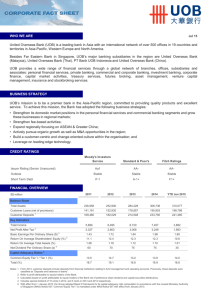

Risk Assessment Guidance The assessor can assign values for the hazard severity (a) and likelihood of occurrence (b) (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Hazard Severity Remote 1 (eg discomfort, slight bruising, self-help recovery) (eg small cut, abrasion, basic first aid need) (eg strain, sprain, incapacitation > 3 days) (eg fracture, hospitalisation >24 hrs, incapacitation >4 Likelihood of Occurrence 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (b) (almost never) (occurs rarely) (could occur, but uncommon) (recurrent but not frequent) (occurs frequently) (single or multiple) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Fatal Serious Moderate Minor Trivial 1 – Trivial 2 – Minor 3 – Moderate 4 – Serious weeks) 5 – Fatal (a) Rating Bands (a x b) 2 3 4 5 4 6 8 10 LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but implement additional reasonably practicable controls where possible and monitor regularly -STOP THE ACTIVITY- Unlikely 2 Possible 3 6 9 12 15 4 8 12 16 20 5 10 15 20 25 Likely Very likely UOB Risk Assessment Continue, but review periodically to ensure controls remain effective Identify new controls. Activity must not proceed until risks are reduced to a low or medium level University Health, Safety & Environment Unit Risk Assessment Record Risk Assessment of: 6E1.2 Materials lab Assessor(s): David Williams Overview of activity / location / equipment / conditions being assessed: 6 East 1.2 is a small clean laboratory housing a selection of analytical equipment. Its use involves the use of a number of hazardous chemicals, compressed gases and liquid nitrogen. Generic or specific assessment? Generic risk assessment Context of assessment (delete as appropriate): planning stage / ‘desk-top’ exercise / site visit / in consultation with # Hazard(s) identified Persons affected employees / in consultation with managers / other (please describe) Existing controls & measures 1 Injury from being in the labs Al users/visitors Technicians, staff, postgraduates, undergraduates, visitors 2 Trip/slip hazards UOB Risk Assessment Date: 12-08-2015 No unauthorised personnel are allowed in the room Visitors must be supervised at all times and follow instructions given by host and lab staff. Anyone working in the labs must wear relevant PPE as appropriate. All lab users/visitors should be mindful of activities taking place in the labs and be prepared to adapt their work if necessary. Floors to be kept clean and clear from liquid contamination and obstructions at all times to reduce trip hazards. Spillages should be cleared up immediately. A B A x B 3 2 6 2 2 4 Additional controls required University Health, Safety & Environment Unit # 3 Hazard(s) identified Asphyxiation from oxygen depletion Persons affected Existing controls & measures All personnel 4 Cold burns from contact with liquid nitrogen Technicians, staff, postgraduates, undergraduates 5 Poisoning from use of mercury Technicians, staff, postgraduates, undergraduates UOB Risk Assessment There is a risk of low oxygen levels due to the gases stored in the room Stored compressed gases should be checked for leaks on installation Gases only to be installed by trained & competent personnel Regulators on gas cylinders should be checked annually for signs of wear/damage and replaced regardless after 5 years The room is fitted with an oxygen depletion monitor to warn of low levels (see instructions on door) – if the alarm triggers, no-one is to enter the room, and it must be vacated. An extraction fan to assist ventilation can be operated by the switch outside the room. Liquid nitrogen should only be handled by those trained and competent. Correct PPE to be worn when working with liquid nitrogen (full face visor, lab coat and gloves). Dewars are to be kept out of the way when not in use to prevent contact with cold parts of the equipment. Liquid nitrogen is only to be stored in suitable containers. Any user must have carried out a COSHH assessment prior to the commencement of work Any use of exposed mercury must be carried out inside the fume cupboard (switched on). The front of the fume cupboard must be fully down when in use. Fume cupboard will be serviced annually by competent professionals The lids of all containers for mercury must be checked for tightness Mercury not in use will be kept in a locked chemicals cupboard to prevent unauthorised access. A mercury spill kit is kept readily available next to the area of use. A B A x B 4 1 4 5 1 5 3 1 3 Additional controls required University Health, Safety & Environment Unit # Hazard(s) identified Persons affected A B A x B 3 2 6 Before commencing any work with hazardous substances, users must familiarise themselves with the individual hazards associated with these by reading the MSDS. Any user must have carried out a COSHH assessment prior to the commencement of work Appropriate PPE must be worn All users of equipment must have received training prior to equipment use 3 2 6 Existing controls & measures 6 7 Use of hazardous substances Technicians, staff, postgraduates, undergraduates Technicians, staff, postgraduates, undergraduates Assessor signature: Use of equipment UOB Risk Assessment Additional controls required Print name: Review date: David Williams July 2015 University Health, Safety & Environment Unit Risk Assessment Action Plan Action Plan in respect of: Ref no. Prepared by: Action to be taken, incl. Cost Responsible manager’s signature: Print name: UOB Risk Assessment By whom Target date Review date Outcome at review date Responsible manager’s signature: Date: Print name: Date University Health, Safety & Environment Unit