TEM analysis on dustiness samples

advertisement

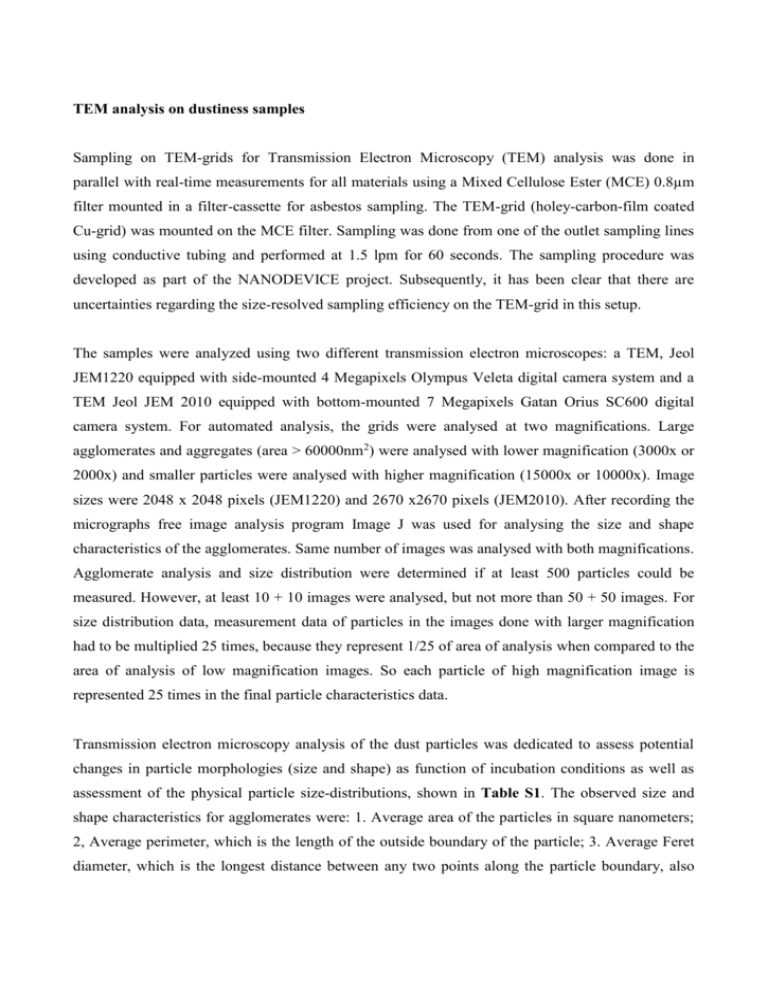

TEM analysis on dustiness samples Sampling on TEM-grids for Transmission Electron Microscopy (TEM) analysis was done in parallel with real-time measurements for all materials using a Mixed Cellulose Ester (MCE) 0.8µm filter mounted in a filter-cassette for asbestos sampling. The TEM-grid (holey-carbon-film coated Cu-grid) was mounted on the MCE filter. Sampling was done from one of the outlet sampling lines using conductive tubing and performed at 1.5 lpm for 60 seconds. The sampling procedure was developed as part of the NANODEVICE project. Subsequently, it has been clear that there are uncertainties regarding the size-resolved sampling efficiency on the TEM-grid in this setup. The samples were analyzed using two different transmission electron microscopes: a TEM, Jeol JEM1220 equipped with side-mounted 4 Megapixels Olympus Veleta digital camera system and a TEM Jeol JEM 2010 equipped with bottom-mounted 7 Megapixels Gatan Orius SC600 digital camera system. For automated analysis, the grids were analysed at two magnifications. Large agglomerates and aggregates (area > 60000nm2) were analysed with lower magnification (3000x or 2000x) and smaller particles were analysed with higher magnification (15000x or 10000x). Image sizes were 2048 x 2048 pixels (JEM1220) and 2670 x2670 pixels (JEM2010). After recording the micrographs free image analysis program Image J was used for analysing the size and shape characteristics of the agglomerates. Same number of images was analysed with both magnifications. Agglomerate analysis and size distribution were determined if at least 500 particles could be measured. However, at least 10 + 10 images were analysed, but not more than 50 + 50 images. For size distribution data, measurement data of particles in the images done with larger magnification had to be multiplied 25 times, because they represent 1/25 of area of analysis when compared to the area of analysis of low magnification images. So each particle of high magnification image is represented 25 times in the final particle characteristics data. Transmission electron microscopy analysis of the dust particles was dedicated to assess potential changes in particle morphologies (size and shape) as function of incubation conditions as well as assessment of the physical particle size-distributions, shown in Table S1. The observed size and shape characteristics for agglomerates were: 1. Average area of the particles in square nanometers; 2, Average perimeter, which is the length of the outside boundary of the particle; 3. Average Feret diameter, which is the longest distance between any two points along the particle boundary, also known as maximum caliper; 4. Feret min diameter is the minimum caliper diameter; 5. Circularity (4π × area/perimeter2) with a value of 1 indicating a perfect circle. When the value approaches 0, it indicates an increasingly elongated shape; 6. Aspect ratio of the particle’s fitted ellipse, i.e., major axis/minor axis and 7. Solidity, which is the area of particle /convex area of the particle. Convex area is determined as it replaces a freehand selection of particle with its convex hull. The convex hull is a curve tightly drawn around the points that define the particle. In addition particle size distributions (based on Average Feret diameters) were derived from the image analysis data of the measured dust samples, as shown in Figure S1. Conditions missing from Table S1 and Figure S1 are left out due to insufficient particle sampling for analysis. Even-though the statistics for the size distribution are weak, most samples have a dominating number of particles between 100 nm and 1µm. The exception to this is TiO2 in which the dominating size is between 1 and 10 µm. Even though none of the samples show a clear bi-modal distribution as in the instrument size distributions there are slight tendencies of this in several samples. Other samples such as TiO2 and CeO2 appear more unimodal though. Overall, the uncertainties in sampling efficiency and the low number of counts means that the instrument sizedistributions can neither be confirmed nor disconfirmed based on the microscopy. Table S1. Image analysis results on the size and shape characteristics of the agglomerates. Material Average area (median) nm2 Average perimeter (median) nm Average feret diameter (median) nm Feret min (median) nm Circularity (deviation) Aspect ratio (deviation) Solidity (deviation) ZnO #1 30% 707930 (11500) 1667 (613) 506 (201) 336 (106) 0,55 (0,13) 1,78 (0,38) 0,81 (0,07) ZnO #1 30% + P 276617 (11900) 1243 (551) 396 (193) 265 (128) 0,58 (0,12) 1,60 (0,33) 0,81 (0,06) ZnO #1 50% + P 572824 (17500) 1650 (681) 506 (212) 330 (134) 0,58 (0,17) 1,82 (0,55) 0,82 (0,06) ZnO #2 30% 1977002 (77000) 4029 (1240) 1076 (439) 731 (292) 0,53 (0,15) 1,67 (0,36) 0,79 (0,07) ZnO #2 30% + P 2759080 (83500) 5474 (1460) 1439 (462) 974 (292) 0,48 (0,14) 1,71 (0,44) 0,78 (0,06) ZnO #2 50% + P 710925 (41700) 2410 (1150) 683 (351) 466 (228) 0,58 (0,17) 1,66 (0,36) 0,80 (0,06) TiO2 30% 6500413 (3640000) 11071 (8770) 3395 (2850) 2201 (1885) 0,61 (0,13) 1,59 (0,33) 0,88 (0,05) TiO2 30% + P 8772114 (6280000) 13057 (11500) 4086 (3720) 2655 (2480) 0,58 (0,11) 1,60 (0,34) 0,88 (0,04) CeO2 30% 114952 (4880) 729 (333) 222 (115) 144 (74) 0,52 (0,16) 1,90 (0,55) 0,75 (0,08) CeO2 30% + P 51379 (3520) 536 (275) 171 (96) 115 (64) 0,63 (0,18) 1,67 (0,36) 0,79 (0,07) CeO2 50% + P 101813 (4950) 756 (347) 237 (116) 152 (74) 0,57 (0,16) 1,72 (0,39) 0,77 (0,07) Al2O3 30% 467899 (61000) 2429 (1230) 715 (417) 467 (274) 0,51 (0,15) 1,63 (0,35) 0,76 (0,07) Al2O3 30% + P 1158347 (37800) 3668 (1130) 980 (382) 631 (214) 0,49 (0,14) 1,80 (0,49) 0,77 (0,07) Al2O3 50% + P 967282 (41100) 2973 (1230) 792 (362) 511 (208) 0,47 (0,14) 1,68 (0,28) 0,78 (0,06) a) b) c) d) e) Figure S1a-e. Particle size distributions derived from the TEM image analysis data of dust samples. Environmental SEM water uptake Environmental Scanning Electron Microscopy (ESEM) experiments were conducted with a FEI ESEM Quanta 200 FEG (FEI, Eindhoven, the Netherlands) to investigate the short term water uptake of the materials at varying humidity. The instrument was operated at 10 kV and spot size 3, using a gaseous secondary electron detector (GSED, 500 µm) and a Peltier cooling stage. The relative humidity with respect to water was controlled via regulating the vapour pressure in the chamber between 0.3 and 16 mbar and the temperature at the Peltier stage between 3.5 and 15 degrees Celsius. Relative humidity between 5.8 and 100 % was probed. Protocols of temperature and humidity steps for each sample can be found in the supplementary information. Each step was allowed a conditioning time of 15 minutes. Samples were prepared on by dipping clumps of particles out of the bulk powder on to aluminium stubs and removing large particle by a gentle stream of air. Ensembles of single particles were chosen and observed at four different magnifications. It must be noted that all particles were in fact agglomerates of several µm extension in the projected area. In the short term ESEM measurement none of the powder showed recognizable water uptake below 93.5 % RH. Droplets appeared never below 98.4 % (4 degrees C, 8 mbar) for any material. For TiO2 and CeO2, droplet formation was observed on the aluminium stub when 98.4 % RH where reached. When the humidity was raised to 100 %, droplets started growing and removed particles from their actual positions by floating around on the substrate. Particles were thus aligned on the moving margins of growing droplets. Particles were not observed to change their morphology and microstructure. The conditions where maintained for observation up to 20 minutes. Within that time frame, the particles did not dissolve in water or migrate into the droplets. For ZnO #1, droplet formation was observed at 98.4 RH, as well on the stub as on particles. When the humidity was risen to 100 %, a morphological change of particles was observed. However, most particles were removed from their positions by floating droplets, as observed for TiO2 and CeO2. In the Al2O3 sample, the grain size of particles was significantly lower than in the other 4 samples. Droplet formation was first observed, when the humidity was above 100 %. Droplets grew rapidly and preferentially at positions with a high particle load. A large droplet formed on the surface of an area of smeared particles, without extending its margins. The investigations suggest that the powders have a very low probability for significant water uptake in the investigated humidity range and time frame. The structure of the material (e.g. original grain size and agglomeration, or baking together) might play a major role that leads to the observed behaviour. Size distributions Figure S2 presents the accumulated size distributions as measured with FMPS and APS of all five materials measured at 30, 50, 70% RH with and without physical loading. a) c) b) d) e) Figure S2 a-e. Accumulated size distributions measured during rotating drum tests. Vertical bars denoted one standard deviation.