CE3503 Expectations – Wastewater Treatment

advertisement

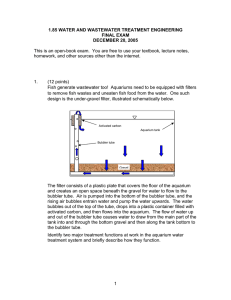

CE3503 Expectations – Wastewater Treatment Legislative Mandate - - Clean Water Act o Fishable-swimmable o Work toward zero discharge o Technology-based treatment standards National Pollutant Discharge Elimination System o Issues discharge permits o Water quality-based treatment standards Wastewater Sources for Publicly-Owned Treatment Works (POTWs) - wastewater from homes and commercial premises infiltration (know definition) inflow (know definition) problems caused by infiltration and inflow - industrial sources o priority pollutants o problems associated with industrial wastes pass-through pollutants harm to plant industrial waste options o treatment handled by industry o industry pre-treats and sends to POTW - Wastewater Collection Systems - connection to house, 6” collecting sewers, gather from houses, 8-12” interceptor or trunk sewers, to plant, 15-27” or larger - designed for gravity flow and to – o prevent in-line sedimentation o rapid transport, avoid anaerobic conditions o avoid scour to pipe Wastewater Characteristics - BOD and SS, 200 mg/L in, 30 mg/L out Ammonia, 25 mg/L in, 2 mg/L out Phosphorus, 10 mg/L in, <1 mg/L out Coliforms, 108 cells/100 mL in, 100 cells/100 mL out Daily variation in wastewater flow Preliminary Treatment - know purpose and method for each o screening (bar racks and screens) o comminutors o grit chambers [design problem, Stokes’ Law] o floatation o flow equalization Primary Treatment - objective and approach basis of method handling of floatables, sludge primary clarifier [design problem, SOR] Secondary Treatment - - microbiological components suspended growth, activated sludge o aeration tank o mixed liquor o mixed liquor suspended solids o secondary clarifier o return activated sludge o waste activated sludge o F/M ratio [design problem, F/M] growth phases settleability BOD removal o Sludge age or solids retention time [design problem, SRT] o Process variations high rate conventional extended aeration o Process modifications plug flow, tapered aeration plug flow, step aeration completely mixed, conventional completely mixed, contact stabilization fixed film o trickling filters [design problem, TF] o rotating biological contactors Tertiary Treatment - a.k.a. advanced waste treatment or AWT suspended solids, filtration dissolved BOD, adsorption phosphorus, precipitation with alum or ferric chloride nitrogen, nitrification to eliminate ammonia denitrification, to remove all nitrogen Disinfection - chlorination ozonation UV Sludge Treatment and Disposal - - - stabilization to reduce odor, putrescibility and pathogens dewatering to make sludge easier to handle in disposal aerobic digestion; long term endogenous phase aeration anaerobic digestion o acid formers o methane formers dewatering o sand drying beds (small plants) o belt filter o centrifuge disposal o landfill o land application o re-use (Millorganite) o incineration fluidized bed multiple hearth furnace co-generation Summary Be able to sketch out a schematic of a wastewater treatment plant. Design Problem 1. Grit Chamber. A wastewater treatment plant will receive a flow of 35000 m3·d-1 (~10 MGD). Calculate the surface area (m2), volume (m3), and detention time (s) of a 3m deep horizontal flow grit chamber which will remove grit with a specific gravity of >1.9 and a size >0.2 mm. Calculate the particle settling velocity (vs) using Stokes’ Law. vs g ( p w ) d 2 18 9.81 (19 . 10 . ) 998 (0.2 x103 ) 2 vs 18 1002 . x103 vs 0.02 m s1 or 1728 m d 1 The design particle (and all larger, denser particles) will be removed if the horizontal velocity within the tank is less than the settling velocity (vh < vs). Calculate the required surface area of the tank. vh A Q or A A Q vh 35000 20.25 m2 1728 Calculate the tank volume. V A H 20.25 3 60.75 m3 Calculate the detention time. V 60.75 0.0017 d 2.5 min Q 35000 Design Problem 2. Primary Clarifier. A wastewater treatment plant will receive a flow of 35000 m3·d-1 (~10 MGD). Calculate the surface area (m2), diameter (m), volume (m3), and retention time of a 3m deep, circular, primary clarifier which would achieve 50% suspended solids removal. What BOD removal efficiency would be expected? Calculate the required surface area. Q 35000 m3 d 1 A 3 2 1 583 m2 SOR 60 m m d Calculate the tank diameter. A r2; r A 583 13.6 m ; D 2r 27.2 m Calculate the tank volume. V A H 583 3 1749 m3 Calculate the retention time. V 1749 0.05 d 12 . h Q 35000 From the design plot, a BOD removal efficiency of ~25% could be expected. Design Problem 3. Activated Sludge - F/M Ratio. A wastewater treatment plant will receive a flow of 35000 m3·d-1 (~10 MGD) with a raw wastewater CBOD5 of 250 mg·L-1. Primary treatment removes ~25% of the BOD. Calculate the volume (m3) and approximate retention time (d) of the activated sludge aeration basin required to run the plant as a “high rate” facility (F/M = 2 d -1). The aeration basin MLSS concentration will be maintained at 2000 mgMLSS·L-1. Calculate the CBOD5 feed to the aeration tank. So 250 mg L1 250 g m3 0.75103 kg g 1 01875 . kg m3 Calculate the MLSS concentration of the aeration tank. X 2000 mg L1 2000 g m3 103 kg g 1 2 kg m3 Use the definition of F/M and the data above to calculate V. F Qo So 35000 m3 d 1 01875 . kg m3 2.0 d 1 3 M VX V 2 kg m V 1640 m3 Calculate the retention time. V 1640 0.047 d 11 . h Q 35000 This retention time is approximate, because the flow estimate does not include return activated sludge. Design Problem 4. Activated Sludge - SRT. A wastewater treatment plant will receive a flow of 35000 m3·d-1 (~10 MGD). Calculate the mass of sludge wasted each day (Qw·Xw, kg·d-1) for an activated sludge system operated at a solids retention time (SRT or c) of 5 days. Assume an aeration tank volume of 1640 m3 and a MLSS concentration of 2000 mg·L-1. What fraction of the solids leaving the aeration tank is this? Set up the SRT design equation. c XV Xw Qw Rearrange and solve for Qw·Xw. Qw Xw X V 1640 2000 656,000 g d 1 656 kg d 1 c 5 Calculate the % of the solids leaving the aeration tank. Waste sludge 656 1% 35000 2 Design Problem 5. Trickling Filter. A wastewater treatment plant will receive a flow of 35000 m3·d-1 (~10 MGD) with a raw wastewater CBOD5 of 250 mg·L-1. Primary treatment removes ~25% of the BOD. Calculate the diameter (m) of the 3m deep trickling filter(s) which would accommodate a hydraulic loading of 5 m3·m-2·d-1 and an organic loading of 250 gCBOD·m-2·d-1. Calculate the CBOD5 load to the filter. CBOD Load 250 mg L1 0.75 35000 m3 d 1 6562500 g d 1 Calculate the required filter area based on CBOD loading. CBOD Load 6562500 g d 1 2 A 2 1 26250 m Design Organic Load 250 g m d Calculate the diameter. A A r2; r 26250 91 m ; D 2r 182 m Thus, ~9 filters with an area of 2831 m2 (60m diameter) would be required. Calculate the required filter area based on the hydraulic loading. Hydraulic Load 35000 m3 d 1 2 A 3 2 1 7000 m Design Hydraulic Load 5 m m d Calculate the diameter. A r2; r A 7000 47 m ; D 2r 94 m Thus, ~3 filters with an area of 2831 m2 (60m diameter) would be required. The design must be made to accommodate both the BOD and hydraulic loads, therefore the BOD design criterion governs here.