Acton Wastewater Treatment Plant Expansion Design Presentation

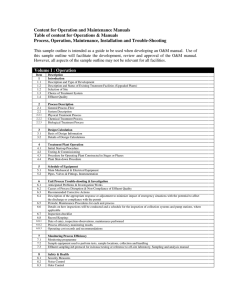

advertisement

WEF SDC 2011 Expansion of Acton WWTP University of Guelph Team: Alexandra Chan Adam Erb Cynthia Mason Julia Veerman October 16, 2011 Outline Introduction Population Analysis Process Selection Phase 1 Design Modeling Noise & Odour Control Construction Phase 2 Design Economic Evaluation Conclusions and Recommendations Review of Existing Facility Problem Statement Current WWTP operating near peak capacity Need to increase capacity to accommodate projected growth in two phases Meet projected effluent criteria Design Basis Parameter Average Daily Flow (dry weather) Maximum Daily Flow (dry weather) Instantaneous Peak Flow (wet weather) Current (m3/day) 4610 Phase 1 Given (m3/day) 5600 Phase 2 Given (m3/day) 7000 6160 9690 14307 15980 14955 21452 Parameter Existing Effluent Objective/Limit Proposed Effluent Objective/Limit BOD5 (mg/L) 2/5 2/5 TSS (mg/L) 3/5 3/5 0.2/0.3 0.1/0.2 1.0/2.0 1.0/4.0 -/0.1 1.0/2.0 1.0/4.0 -/0.016 -/0.08 100/150 100/150 Total Phosphorus (mg/L) (Ammonia + Ammonium) Nitrogen (mg/L) Non-freezing period (May 1 to Nov 31) Freezing period (Dec 1 to April 30) Unionized Ammonia (monthly average) (mg/L) Unionized Ammonia (any single sample) (mg/L) Escherichia Coli (monthly geometric mean density) (#of organisms/100mL) Population Analysis Predicted linear growth Assumed water saving devices at 10% Infiltration/Inflow at 204 L/c/d Parameter Current Phase 1 Given Phase 1 Calculated Phase 2 Phase 2 Given Calculated ADF 4610 5600 7628 7000 8574 MDF 6160 9690 10193 14307 11456 Peak 15980 14955 26442 21452 29721 Process Selection Constraints Accommodate design flows Meet effluent discharge limits Use available land Be compatible with existing facility Criteria Cost effectiveness Integration with existing facility Environmental impact and footprint minimization Phase 1 Design Process Flow Primary Clarifier Primary Clarifier Add two rectangular clarifiers New volume 256 m3 ADF SOR of 27.5 m3/m2/day Maximum day flow 62.5% TSS removal 40.3% BOD removal Chain & scraper sludge collector and scum removal system Secondary Treatment Aeration System Two conventional plug flow activated‐sludge system with nitrification Accommodate 1275 m3/d required Target MLSS = 4000 mg/L SRT = 12 days Fine bubble aeration Positive displacement blower Designed for max day flow + additional feedback flow Secondary Clarifier Two additional secondary clarifiers Limiting solid flux concept MLSS = 6620 mg/L Overflow = 31 m3/m2d Chain & scraper sludge collector and scum removal system Max day flow design Tertiary Treatment Chemical Addition 85 mg/L liquid alum with 45% purity – 824 kg/d Addition point in activated sludge tank Plant B Alum Dose Determination 1,000 Alum Dose (mg/L) At 95%, alum dose = 85 mg/L 100 10 1 10 Percent of values equal to or less than indicated value 100 Filtration Dual media deep bed filtration Existing filters work well to meet limits Widely accepted in WWT Easily retrofit Leopold™ Type S™ Underdrain Air scour + surface wash backwash Max day flow design with one filter out of commission SLR of 7.2 m3/m2/h http://www.wateronline.com/product.mvc/Universal-Type-S-Underdrain-0002 UV Disinfection UV selected as best disinfection method Trojan UV3000Plus™ system LP/HI lamp Automatic and continuous dose pacing Automated mechanical/chemical cleaning Automatic level controller Sized for peak flow Solids Handling Bio-Solids Digester Sequential dual-stage digester series Add new series in parallel Methane gas collected for heating Thermophillic Stage 1 SRT 2 days Recirculation pump mixing Mesophillic Stage 2 SRT 8 days Sludge Drying Belt press drying after digester Polymer addition Increases solids concentration from ~3% to ~25% Cost-effective in disposal Reduces footprint Mass Balance System Controls and Instrumentation Control strategy Increased control and monitoring Small relative capital cost Significant efficiency improvements Biological treatment Aeration accounts for up to 50% energy consumption Matched oxygen demand profile Intelligent feedback control for aeration, RAS, WAS System Controls and Instrumentation Clarifiers Monitoring Sludge pumping control mechanisms Digesters Control for feeding rates, recirculation, heating, withdrawal Tertiary Treatment Flow splitting SCADA Interfacing with SCADA for remote monitoring Hydraulic Profile Phase 1 – Model Inputs Projected peak influent concentrations and flows Proposed plant sizing Clarifier modeling based on Lessard and Beck dynamic model Activated sludge modeling completed using the IAWQ1 model Phase 1 – Model Results BOD and NH3 water quality requirements met Model Shortcomings: Chemical phosphorous treatment or tertiary filtration not accounted for Odour and Noise Control Currently no odour or noise issues Reduce odour and noise Buffer zone Housing potential equipment Construction Completion in 24 months Best management practices: Construct in phases Protect waterways Provide training Conduct inspections Phase 2 Conceptual Design Phase 2 Conceptual Design Modify Plant B aeration basin configuration to plug flow + BNR Investigate: Membrane technology Phosphorus extraction Phase 1 – Capital Cost Total Capital Cost Estimate = $24M Phase 1 – O&M Cost Annual O&M Cost Estimate = $1.2M Phase 2 – Capital Cost Total Capital Cost Estimate = $12M Conclusions Expansion design to increase the Acton WWTP capacity Preliminary Phase 1 design Additional clarifier, disinfection, and anaerobic digestion trains CAS + nitrification Deep bed dual media filter Belt press Conceptual Phase 2 design Recommendations Implement sewer system improvement plan Conduct more simulations Obtain more cost-specific information from manufacturers Conduct pilot tests Acknowledgements Dr. Hongde Zhou, P.Eng., University of Guelph – Faculty Advisor David Arsenault, P.Eng., CH2M Hill – Consulting Advisor Rafiq Qutub, P.Eng., WEAO – SDC SubCommittee Chair Lauren Zuravnsky, P.E., WEF – Design Competition Sub-Committee Chair