Fast pyrolysis of biomass,

improving the oil quality.

PhD. Student: Stijn Oudenhoven

Thesis advisor: Prof. dr. S.R.A. Kersten

Supervisor: dr. ir. R.J.M. Westerhof

Research group: TNW/SPT

Supported by: CatchBio

Phone: +31 (0)53 4894418

E-mail: s.r.g.oudenhoven@utwente.nl

URL: www.utwente.nl/tnw/spt

Research school: OSPT

Period: feb 2012-jan 2016

Introduction: Fast pyrolysis of biomass is a

Objective: Stijn is working within the CatchBio

promising

project

technique

to

depolymerize

“Catalytic steps in the conversion of

lignocellulosic biomass, this is required to produce

lignocellulosic

fuels

During

precursors”. In this project his goal is to develop

elevated

methods to improve the oil quality already within

and

pyrolysis

chemicals

biomass

from

biomass.

decomposes

at

temperatures and in the absence of oxygen into

the

gasses, oil and char. The pyrolysis oil is a complex

processing.

mixture

of

water

and

a

large

variety

pyrolysis

biomass

via

process

pyrolysis

to

to

improve

fuel

further

of

oxygenated organic compounds. The composition

of the oil is determined by the biomass feedstock,

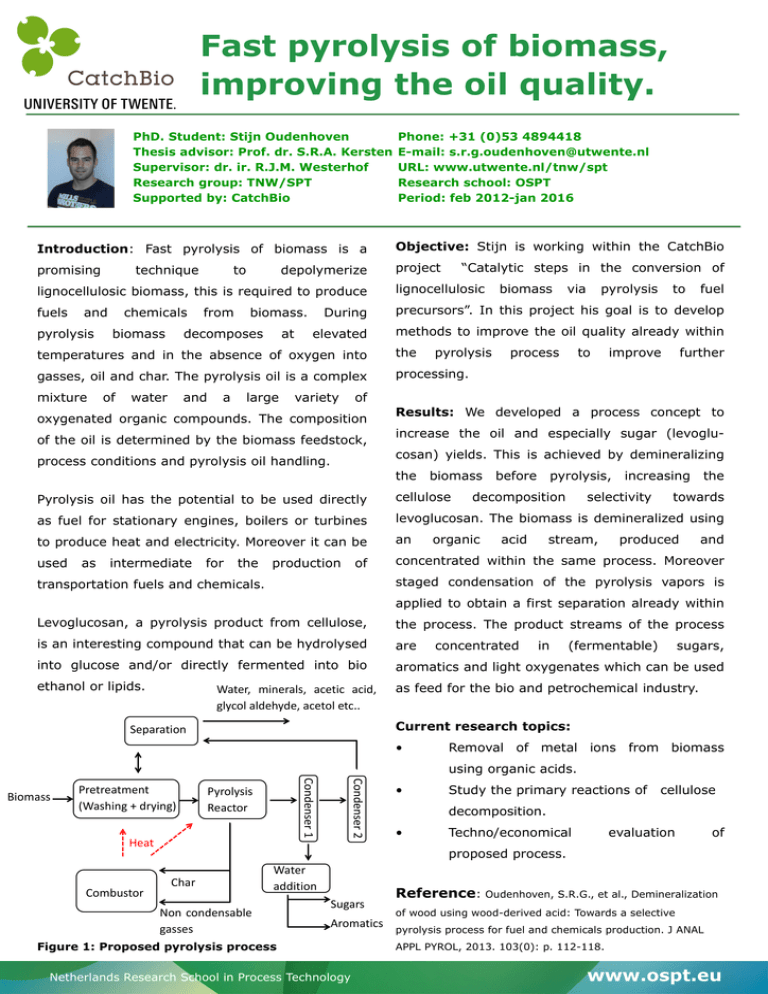

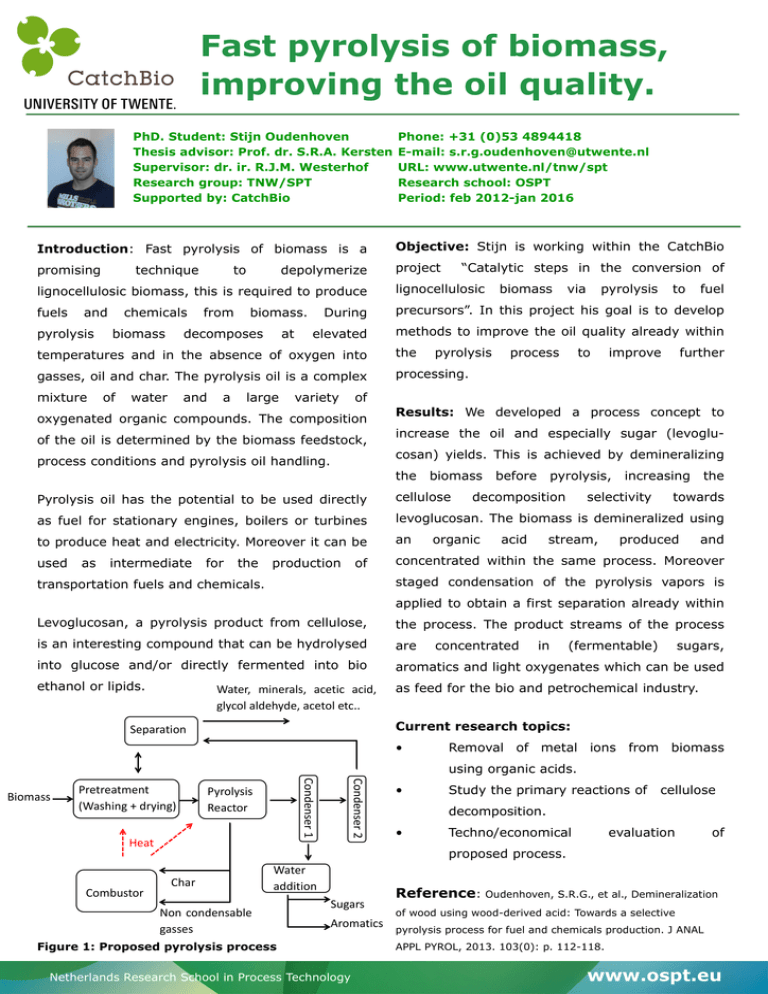

Results: We developed a process concept to

increase the oil and especially sugar (levoglucosan) yields. This is achieved by demineralizing

process conditions and pyrolysis oil handling.

the

biomass

before

pyrolysis,

cellulose

as fuel for stationary engines, boilers or turbines

levoglucosan. The biomass is demineralized using

to produce heat and electricity. Moreover it can be

an

used

concentrated within the same process. Moreover

intermediate

for

the

production

of

organic

acid

selectivity

the

Pyrolysis oil has the potential to be used directly

as

decomposition

increasing

stream,

towards

produced

and

staged condensation of the pyrolysis vapors is

transportation fuels and chemicals.

applied to obtain a first separation already within

Levoglucosan, a pyrolysis product from cellulose,

the process. The product streams of the process

is an interesting compound that can be hydrolysed

are

into glucose and/or directly fermented into bio

aromatics and light oxygenates which can be used

ethanol or lipids.

as feed for the bio and petrochemical industry.

Water, minerals, acetic acid,

glycol aldehyde, acetol etc..

concentrated

in

(fermentable)

sugars,

Current research topics:

Separation

•

Removal of metal ions from biomass

using organic acids.

Pyrolysis

Reactor

Heat

Combustor

Condenser 2

Condenser 1

Biomass

Pretreatment

(Washing + drying)

•

Study the primary reactions of

cellulose

decomposition.

•

Techno/economical

evaluation

of

proposed process.

Char

Water

addition

Non condensable

gasses

Sugars

Aromatics

Figure 1: Proposed pyrolysis process

Netherlands Research School in Process Technology

Reference: Oudenhoven, S.R.G., et al., Demineralization

of wood using wood-derived acid: Towards a selective

pyrolysis process for fuel and chemicals production. J ANAL

APPL PYROL, 2013. 103(0): p. 112-118.

www.ospt.eu