Catalytic de-oxygenation of woody biomass pyrolysis vapours over zeolite-bentonite catalysts

advertisement

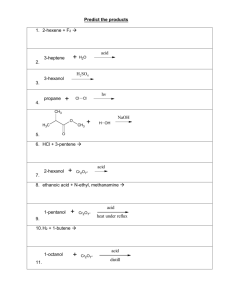

Catalytic de-oxygenation of woody biomass pyrolysis vapours over zeolite-bentonite catalysts Atte Aho, Narendra Kumar, Kari Eränen, Tapio Salmi, Dmitry Murzin, Mikko Hupa Objective Study the pyrolysis of pine wood biomass in a fluidized bed reactor for the production of valuable fuels and chemicals Upgrading of the pyrolysis vapours through catalytic de-oxygenation over zeolite-bentonite catalysts Pyrolysis of Biomass Gases Pine Biomass Pyrolysis without O2 400 °C Char Gases Condensation Bio Oil Catalytic de-oxygenation Conventional pyrolysis oil highly oxygenated Quality improved by removing oxygen from oil molecules Upgrading over zeolites Low temperatures, oxygen removed as water Higher temperature, CO2 and CO Reactor set-up 450 °C -20 °C 400 °C Experiments Pine as biomass raw material (355 – 500 µm) Quartz sand in the lower bed (100 – 150 µm) Five different runs Empty upper bed (non-catalytic) Bentonite/H-ZSM-5-23 (250 – 355 µm) Bentonite/H-Beta-25 H-ZSM-5-23 H-Beta-25 Acidic Zeolite Catalysts Beta 3-D, 12 ring 0.76 x 0.64 nm 0.76 x 0.64 nm 0.55 x 0.56 nm ZSM-5 3-D, straight 10 ring 0.52 x 0.57 nm Sinusoidal 0.53 x 0.56 nm Intersection cavity ( 0.9 nm) Surface area 450 – 500 m2/g (300 – 400) Temperature profile Bed Catalyst Furnace 500 Pyrolysis Reactions Temperature [°C] 400 300 N2 flow off 200 100 0 0 50 100 150 200 Time [min] 250 300 350 400 Reaction temperature Bed 480 Catalyst Beginning of experiment 460 20 °C 440 420 20 °C 400 380 205 210 215 220 225 Mass balances 37.6 37.2 38.1 36.3 39.1 Gas (by difference) 18.6 18.9 2.7 16.6 22.9 19.0 16.2 4.2 0.6 Organic phase 21.7 24.8 16.8 15.0 2.1 Aqueous phase Coke on catalyst 0.0 22.2 23.0 22.2 23.1 21.1 Hybrid ZSM-5 Hybrid Beta ZSM-5 Beta-25 non-catalyzed Char (biomass residue) Chemical composition Empty 1 2 3 4 5 Hybrid ZSM-5 6 7 8 9 Hybrid Beta 10 11 12 13 14 15 Products CH3 CH3 O OH O CH3 H3C O H3C OH acetic acid OH levoglucosan O O H3C OH 2-methoxy-4-methylphenol H2C O O CH3 O HO OH 2-methoxy-4-[(1E)-prop-1-en-1-yl]phenol 1-hydroxyacetone O HO CH3 H3C OH 1-(4-hydroxy-3-methoxyphenyl)ethanone O OH 2-methoxyphenol OH 2-methoxy-4-vinylphenol O O OH H3C 2-hydroxycyclopent-2-en-1-one O O O OH 4-hydroxy-3-methoxybenzaldehyde CH3 furan-2(5H)-one Conclusions De-oxygenation over catalysts changes the yield of the organic phase, aqueous phase and coke Chemical composition of the oil changes during upgrading Hybrid materials more active than pure zeolites Beta more active than ZSM-5 Thank you for your attention