Nuts and Bolts of PI-II at WBH

advertisement

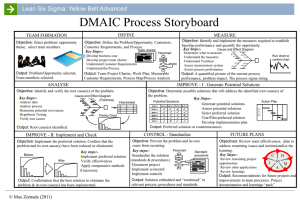

Nuts & Bolts of PI-II at WBH •Understanding Performance Improvement •Overview of Deployment Model Presented by Jayant Trewn Ph.D., Faculty and Master Black Belt Beaumont University 1 Components of a Culture Change Culture Change Criteria WBH Status Empower Staff to Enable Change Top Leadership Sponsorship Provide a support structure for projects and frontline staff Mentors and Experts - MBB, BBs and GBs on board Self Sustaining Structured Approach Method for spread Learn - Practice - Train environment for Ybs PI-II Structured Project Guide Snowball from grassroots campaign Provide Knowledge and training Beaumont University Motivation driven by rewards Linked to Pay for Performance 2 PI-II Environment Margins Green Belt Lean Expert Cost COST Process Capability Lean/Waste removal Facilitator – Black Belt 3 Performance Improvement Models Improvement Model Primary Theory Intended Effect Improve performance PDCA - Rapid through incremental Cycle Improvement process changes Achieve pre-defined measures of success Six Sigma Reduce process variation Reduce variation in complex processes Lean Thinking Remove waste Create value-added processes 4 PDCA Overview 5 Quality : the old view •Products and services that are exactly to specifications •In many cases even outside the specifications 6 The TQM view • Products and services that totally satisfy the customer’s needs and expectations in every respect on a continuous basis. In fact they do not just satisfy but delight the customer 7 Quality is customer delight 8 Q: What delights the customer? • product quality cost delivery service • All these constitute • • • Q 9 Total • T = Quality of all products – all services – all processes – – Team work - all employees - working together to achieve Q 10 Management • M = Management – integrated approach – proper problem solving methodology – continuous improvement 11 The TQM Model JIT : just when customer wants it exposes problems TQC : problem solving methods kills problems TEI : total employee involvement people are the key World World Class Class JIT TQC TEI ‘If you don’t improve you deteriorate’ Through Throughcontinuous continuous improvement improvement 12 Total Quality Control TQC - The heart of TQM 13 TQM vs. Problem Water high problems hidden Water lowered problems exposed Water reduced problems minimised problems 14 Quality target • Target is 100% not even 99.9% – 2-3 rail accidents every day – 25 bombs off target in Kosovo 15 100% inspection • “The necessity of training farm hands for the first class farms in the fatherly handling of farm livestock is foremost in the minds of farm owners. Since the forefathers of the farm owners trained the farm hands for the first class farms in the fatherly handling of farm livestock, the farm owners feel they should carry on with the family tradition of training farm hands of first class farms in the fatherly handling of farm live stock because they believe it is the basis of good fundamental farm management.” 16 How to kill problems - PDCA • Problem solving – seven steps – data - in god we trust, the rest of us bring data • fact finding • 7+ 7 QC tools • Continuous improvement - PDCA • Maintenance of improvement - process control average and variability • Systems and procedures - Standard Operating procedures • People and systems - who is the problem? 17 7 QC tools • • • • • • • stratify data Pareto diagram cause and effect diagram histogram scatter diagram check sheets control charts 18 7 new quality management tools • • • • • • Affinity diagram Interrelationship digraph Prioritization matrices Matrix diagrams Tree diagram (systematic diagram) Process Decision Program Chart (PDPC) • Activity Network Diagram 19 20 Six Sigma Problem Solving 21 What is Six Sigma? • A business philosophy and initiative that enables World Class quality and continuous improvement to achieve the highest level of Customer Satisfaction. 1 • Yields dramatic bottom line results by redesigning and monitoring activities to minimize cost and resources • Drives companies to reduce variation, increase quality, and generate increased customer responsiveness. 1Black Belt Memory Jogger, 2002 Goal/QPC and Six Sigma Academy 22 What is Six Sigma? • A comprehensive and flexible program for achieving, sustaining and maximizing business success that: – Is uniquely driven by a clear focus on the “Voice of the Customer” – Is founded in a rigorous use of facts, data and statistical analysis – Provides for diligent attention on managing, improving and reinventing business processes. – Is a management methodology with three perspectives: • A Measure of Quality • A Process for Continuous Improvement • An Enabler for Cultural Change 23 A Measure of Quality: • Six Sigma is a statistical measure that expresses how close a service process comes to its quality goal • Six Sigma refers to a process that produces only 3.4 defects per million opportunities Sigma DPMO Yield 2 308,537 69.1463% 3 66,807 93.3193% 4 6,210 99.3790% 5 233 99.9767% 6 3.4 99.9997% 24 Six Sigma Problem Solving • Variation Reduction • Project Management Tool – Structured Project Guide 25 Six Sigma Vision • Every project will contribute to profitability and meeting customer needs Six Sigma Strategy • Need to balance needs of customer and company so both are happy 26 What is Six Sigma? • Drives your company to work in a proactive mode and focus on prevention • Utilizes data and statistical tools to improve processes 27 Six Sigma Roles • • • • • • Black Belts Master Black Belts Green Belts Executive Sponsors Champions Process Owners 28 What is Variation? 29 Service Process Variation • Variations in inputs to process • Variations in process execution • Variation in outputs of process 30 Defining KPOV and KPIV 31 KPOV & KPIV Y = f (x) KPOV KPIV Key Process Output Variable Key Process Output Variable 32 Key Process Output Variable Customer Needs / Data Supplier Inputs Process Data Processes Outputs Customer Output Measures (KPOVs) Performance outcomes More direct and short term Easy to quantify & dashboard-able Process Measures (KPIVs) How effectively the process is working Possible to Quantify 33 KPOV Example Output(s) Key Process Output Variable Strength Aroma Coffee Quantity Taste ‘Hot-ness’ 34 KPIV Input(s) Ingredient list Milk Water Sugar Key Process Input Variable Completeness Fat Content Quantity Quantity Type - Ordinary (or) Mineral Quantity Type - Sacrine, Sugar grains, Sugar cubes Quantity Coffee Powder Chicory % Type - instant or filter 35 KPIV Classification Input Type Description Controllable KPIVs that can be changed to see the effect on KPOVs, also known as knob variables Critical Inputs whose variation will impact KPOVs Uncontrollable (difficult / unable to control) Input variables that impact the KPOV’s but are difficult to control. Example: Environmental variables such as humidity, temperature etc… Not controlled Inputs that are uncontrollable but chosen not to be controlled 36 Input 1 Input 2 Input 3 …….. Input n People Machines Output 1 Output 2 Output 3 …….. Output z Process Methods Materials Control KPIVs Monitor KPOVs Desired Outcomes Design Process Noise 1 Noise 2 ……. Noise m Controllable factors The Six Sigma Model Uncontrollable factors Absorb variation 37 Clean Set Complete Set Missing instrument list Timely set delivery Organized as set Replacement instruments Set tray CPD Techs ORAs Decon m/c Sterlizer Labeled Set No missing inst No dirty inst No broken inst Sterilized inst Set Processing Set Assy Procedure Kim guards Control KPIVs Damaged instrument Monitor KPOVs Desired Outcomes Process: Preparing Carts in CPD for OR cases Sub Process: Process Sets - Assembly Broken Instrument Controllable factors Example of The Six Sigma Model KPOV/KPIV Absorb variation Uncontrollable factors 38 DMAIC Methodology: 39 PDCA – Six Sigma MAP 1. Define Problem 2. Identify Customer 3. Identify CTQ 4. Map Process 5. Refine Project Scope 6. Update Project Charter 1. Conduct ErrorProofing 2. Develop Long Term Measurement Plan 3. Implement Control Charts 4. Develop SOP and Training Plan 1. Identify Metrics 2. Determine Data 3. Develop Data Collection Plan 4. Collect Data 1. Select Analysis Tools 2. Graphically Represent Results 3. Identify Sources of Variation 1. Generate Improvement Opportunities 2. Select Best Alternative 3. Map New/Improved Process 4. Conduct FMEA 5. Pilot Solution 6. Validate Improvement 40 Structured Project Guide • What is a Structured Project Guide? – Structured approach – ensures success • Objectives of guide – Plan – Guide – Track progress – Review – Evaluate – Document 41 Structured Project Guide Framework • Tollgate Model – 8 Tollgates – Travel to a Tollgate – Pay Toll – Start journey to next Tollgate • Structured progress • Progress tracking – Tollgate reviews 42 Approach Guide Tollgates • DEFINE • Tollgate 1 • Tollgate 2 • MEASURE • Tollgate 3 • ANALYZE • Tollgate 4 • Tollgate 5 • IMPROVE • Tollgate 6 • Tollgate 7 • CONTROL • Tollgate 8 43 Lean in Healthcare 44 Lean Thinking 45 A. A. Milne Winnie-the-Pooh Here is Edward Bear, coming downstairs now, bump bump bump on the back of his head, behind Christopher Robin. It is, as far as he knows, the only way of coming down stairs, but sometimes he feels that there really is another way, if only he could stop bumping for a moment and think of it. 46 The Concept Behind Lean Thoughtware... Significant Sustainable Competitive Advantage Lean Behavior Lean Thoughtware 47 Lean Thoughtware 1. Value can only be defined from the end user customers perspective (Value) 2. To deliver customer value, the “waste” must be removed from the customer delivery process. (Value Stream) 3. Once the waste is removed, the value must be linked together in a continuous flow (Flow) 4. The flow must deliver to the exact customer requirements (pull) 5. Additional waste is eligible to be removed (continuous improvement) 48 A Customer Perspective …is a Lean Perspective To be customer focused..an organization must be process and lean focused “Our processes, more than our products or services tell us where and how we are best prepared to compete" 49 What is Lean? Lean is a Disciplined, Process Focused “Production” System* whose objective is to minimize the consumption of resources that add no value to a product or service…meaning: Lean is the identification and elimination of “muda” or “waste”. 50 About Lean • The disciplined process focused production system known a Lean production was born out of the Toyota Production System “ The Toyota production System, however is not just a production system. I am confident it will reveal its strengths as a management system…” Source:T.Ohno, Toyota Production System (1988) 51 5 Critical Concepts of Lean 1. 2. 3. 4. 5. Lean Thoughtware and Application are based on 5 Critical Concepts: Specify Value Identify the Value Stream Make the Value “Flow” “Pull” to Customer Demand Pursue Perfection 52 Not Just a Manufacturing thing Analysis of Cycle times and Value Adding Activities in White Collar Processes Source: Blackburn, Time Based Competition) Industry Process Average Cycle time Value Adding Time % Value Added Life Insurance New Policy Application 72 hours 7 min 0.16% Consumer Packaging New Graphic Design 18 days 2 hours 0.14% Footwear Prototype Development 25 weeks 2 days 2.60% Commercial Bank Consumer Load 24 hours 34 min 2.36% Hospital Patient Billing 10 days 3 hrs 3.75% Motor Vehicle Equipment Financial Endof Month Closing 11 days 5 hrs 5.60% Airframe MFR. Engineering 21 days 1.75 days Source:Blackburn, Time Based Change Orders Competition. 8.5o% 53 Nationally Known Healthcare Systems using Six Sigma • BJC Healthcare • Catholic Healthcare West • Good Samaritan Health System • Johns Hopkins • Mayo Clinic • New England Medical Center in Boston • NewYork-Presbyterian Hospital • North Shore Long Island Jewish Health System • St. John Health (SJH) • St. Jude Medical • Stanford University Medical CenterDepartment of Radiology • Trinity Health • University of Virginia (UVA) Medical Center • M. D. Anderson Cancer Center • Yale-New Haven Hospital 54 Organizations that admit to using Lean Techniques • • • • • • • Toyota • General Motors • Dell • Oracle • Southwest Airlines • Mayo Clinic • University of Michigan Health System DaimlerChrysler (LaSorda) Ford Motor Company Boeing McKinsey & Company U.S. Army Lockheed Martin 55 Organizations that are teaching Lean Techniques • • • • • • • • Harvard MIT JCAHO Purdue University of Michigan Oakland University Oakland Community College Institute for Healthcare Improvement • AICPA • GE Healthcare • Agency for Healthcare Research and Quality • Michigan Center for Nursing • American College of Healthcare Executives • American Society for Healthcare Engineering 56 57 What is Lean in Health Care? “The endless transformation of waste into value from the customer’s perspective”. Womack and Jones, Lean Thinking 58 Lean in Health Care? • Can healthcare use - the Toyota Production System: - product development - production - supplier management - customer support - planning - to transform waste into value? • Can a health system use: - fewer inputs (time, human effort, materials) - than traditional care process - to produce a wide variety of “products” - with fewer “defects” more quickly with less stress? • Lean is not about working harder or faster, it is about finding waste and transforming it into value our customers want. 59 The 5 Steps of Lean Can Work in Healthcare • Specify value from customer’s perspective • Identify the value stream for each product, and remove the waste • Make value flow without interruptions from beginning to end • Let the customer pull value from our process • Pursue perfection – continuous improvement – Do this every day in all our activities Source: Womack & Jones: Lean Thinking 60 The clinic appointment • You call the clinic, go through 3 voice prompts, are put on hold, and leave a message • The clerk calls you back and sets a date in 3 weeks • You arrive for the visit, check in, sit in waiting room • You are called into the exam room, wait for doctor • The doctor sees you, saying she’s been waiting for you to arrive; diagnoses a URI, and BP is worse • The doctor prints an antibiotic prescription, goes to the staffroom to get it. You are allergic to that drug. • You wait to pick up the prescriptions. • The doctor says she wants to see you back in a week, no appointment is available. • The MA does an EKG. 61 The clinic appointment • You call the clinic, go through 3 voice prompts, are put on hold, and leave a message • The clerk calls you back and sets a date next week • You arrive for the visit, check in, sit in waiting room • You are called into the exam room, wait for doctor • The doctor sees you, saying she’s been waiting for you to arrive; diagnoses a URI • The doctor prints an antibiotic prescription, goes to the staffroom to get it. You are allergic to that drug. • The MA does an EKG. • At check out you ask the cost – clerk says they’ll bill you 62 The 5 Principles of Lean Work • Specify value from customer’s perspective – A quick clinic visit • Identify the value stream for each product, and remove the waste – Time on hold, callbacks, walking • Make value flow without interruptions from beginning to end – No waiting • Let the customer pull value from the process – Pull the appointment when you want it • Pursue perfection – continuous improvement – Every clerk, doctor and nurse works to redesign for better value to the customer 63 Diversity in Healthcare as a Challenge to Lean • Large number of “product lines” – – – – – Adult vs. Peds Specialty vs. Primary Care Inpatient vs. Outpatient Surgical vs. Non-surgical Chronic vs. Acute Care • “Each patient is unique” – – – – – – More like a custom repair (job shop) than an auto manufacturer Almost infinite variability in mix of diseases and symptoms Variable: age, family, gender, race, social, insurances factors Variable: health habits, tobacco/alcohol/drugs, compliance Mental health as a primary or complicating problem Patient preferences must be respected 64 Use Lean tools to transform waste into value from the customer’s perspective. Is There Waste (Muda) in Healthcare? • Defects in products • Unnecessary transport of goods • Overproduction of goods • Waiting • Inventories of goods (for process equipment to awaiting future finish or on an upstream processing or activity) consumption • Unnecessary movement • Design of goods and services which do not of workers meet users’ needs • Overprocessing 65 Do the Eight Forms of Waste Make Sense at Beaumont? Overproduction/Production of Unwanted Products: Material Movement and Worker Motion: Waiting: Over-processing: Inventory: First Time Quality Problems: Defects requiring correction: Wasted Creativity of Employees: 66 Decon Performance Improvement Project Project Start 6/22/05 Project End 10/30/05 67 Problem Statement • Workflow in CPD Decon does not capture priority sets to be cleaned. • Missing instruments from sets in Decon have never been tracked and reported back to OR Surgical Services. • No consistent policy for how things should be done in the Decon area. 68 Project Goals • To optimize work flow in the Decon area. • Create a system to prioritize sets for cleaning as they enter the Decon area. • Create a system to track and report missing instruments from sets and reduce instrument loss. • Create a clear policy and procedure book for the Decon area to promote consistency. 69 Processes and Tools Used • Data Collection • Voice of Customer • Pareto Charting • Flowcharting • QFD Function Matrix • Lean/Six Sigma Tools 70 Value Chain Concept Supplier OR Customer Supplier DECONTAMINATION Customer 1. Complete Sets- Include Pans 2. Send Carts ASAP 3. Enzymatic Spray - Rinse Instruments 4. Organize Sets 5. All Sharps Removed 6. Return Paperwork 7. Feedback on Priority sets 8. Feedback on Missing Instruments Customer PROCESSING Supplier 1. 2. 3. 4. 5. 6. Complete Sets Clean Sets Organized Sets Paper pulled out of sets Sets received in timely manner Indicate missing instruments from sets. 7. Priority Set Marker 8. What time set needed for next case 9. Remove extra instruments Instrument Flow 71 Cycle Time Analysis Decon Process VA/NVA 9 9 9 9 9 9 9 Wait times between Value Added Steps Total Non Value Added 33:40 min. Non Value Added Time Value Added 1 2 3 4 5 6 7 Total Value Added 21:00 min. 8 1. Cart arrives in Decon 2. Cart & Set Scanned “Decon Received” 3. Wheel Cart to work Station 4. Sets scanned “Set for Decon” 5. Load Sets onto workstation 6. Separate out hand wash 7. Count instruments & string and clean 8. Cart goes to washer 9. Waiting, Idle Time 72 Discussion • Lean in your department – relate lean to one process of your department and discuss opportunities 73 PI-II Implementation Management of Change 74 The path of the calf • Once upon a time there was a calf. One evening he walked home through a thick jungle. The distance to his home was only one kilometer but he walked three kilometers since, like all calves, he wandered here and there, left and right, up and down. • The next morning a shepherd’s dog passed that way and saw the calf’s hoof marks, and followed the path of this calf through the woods. Shortly after, the first sheep of a flock followed the path and behind him all other sheep. Thus a path was made through the wood. • Men began to use that path, cursing its twists and turns as they did, but doing nothing about it. • The path gradually became a lane, the lane became a road and horses and bullock carts followed it - followed the steps of the wandering calf. • A century later the road became a street, and then a city’s crowded thoroughfare, with thousands following in the footsteps of the wobbly calf. • Three centuries later the road became a street, and then the main street of a very large city, Buses, lorries, trams and cars followed the zigzag path of the calf. 75 Integrated approach to TQM is most necessary – Two levels of implementation • Everyone involved - continuous improvement - small improvement/GHK programme - mass movement • Big problems - cross functional groups – data based – seven steps – group leadership and facilitation 76 PI-II Program Model • • • • • Knowledge Ref: Page 2 of PI-II concept document – BU sponsored and managed curriculum – Progression driven course delivery – Management Development and Leadership Development courses to supplement PI curriculum Tools and Aids – PI-II structured project guide – Progression path YB -> GB -> BB -> MBB – Support structure for learners • GB supported by BB and BB supported by MBB People Ref: Page 3 of PI-II concept document – Empower employees to participate in change – YBs – Empower Supervisors to drive change linked to champion goals – GB – Empower experts to facilitate change – BB – Empower leaders to align goals and objectives to organization strategic plans – Champions Motivation – Tied to Pay for Performance Rewards – Six Sigma and Lean methodology as enablers (means to achieve) of Pay for Performance objectives 77 PI-II Model launch Time Frame Projects 2nd Half 2007 2008 2009 2010 4-6 15-20 60 2/quarter /dept Phase Early Grassroots Rolling Snowballing On-Going Staff Engagement Current Yellow Green Black Current Engage Belts Belts Belts ment Pool Existing 40-60 New 30 Existing 48 New 40 Existing 100 Existing Existing 812 30 New 200 New 60 New 20 Existing 200 Existing 100 Existing 30 New 400 New 60 New 20 Existing 600 Existing 160 Existing 50 New 600 New 60 New 20 YB 90 GB 12 BB 21 GB 12 BB 10 Ref: Page 3 of PI-II concept document 78 Current GB Projects 1 Reduction in biling concern/call routing (Service Excellence - Corporate) Green Belts: Marie Baloga & Julie Morse Black Belts: Wendy Dingwall and Kristen Cavender 2 Reducing/eliminating duplicate chart requests (PT/OT - Troy) Green Belts: Elizabeth Van Hoek & Karol Clason Black Belts: Jayant Trewn 3 Reducing wasted bone products ordered for surgery from the Blood Bank (Blood Bank - RO) Green Belts: Randy Sprouse & Anne Sepienza Black Belts: Judy Easter & Brian Vargo 4 Reducing Critical Call turn-around time for critical lab values (Lab - RO) Green Belts: Bob Church/Terre St. Peter/Connie Diggs Black Belts: Grace Bostic & Salil Balar 5 Entering accurate and complete data into HR database (HR - Corporate) Green Belts: Jean Ann Larson/Carol Holth/Ludmilla Tscherniwetz Black Belts: Eric Ellerholz/Ron Grant 6 Eliminating missed tests/orders (BRL - RO) Green Belts: Bonnie Fegley/Sherri D'Anna Black Belts: Pam Meyer 79 PI-II Delivery Structure Ref: Page 2 of PI-II concept document Champions & Sponsors Yellow Belts Green Belts or Lean Expert Black Belts Role Empower department leaders and frontline staff to improve department performance Participate in PI projects Lead PI projects Facilitate PI projects Motivation Vehicle to set departmental goals and objectives tied to organization strategy Feel empowered to make a change/improve performance Tool to achieve pay for performance objectives Tie practice to pay for performance objectives Reward Achieve pay for Link manager pay for Celebrate project performance performance objectives to objectives success champion objectives various Achieve pay for performance objective - 2 successful projects per year 80 PI-II Progression Matrix Expert Progression Matrix Expert Expectation Recomme- Commitnded ment per Project 1 project activity YB GB or Lean Expert BB MBB PI - 100 PI 200 PI 300 YB Cert Participate in atleast 1 project per year YB + 2 projects as team member OR Supr/Mgr/Dir AND GB class + Cert 2 hours/week + assigned project work 2 hours/week Lead 1 project per + assigned trimester project work + project mgt GB + 2 projects as leader and BB class + Cert Facilitate 1 project per trimester 2.5 hrs per week 0.5 hour per Appointed by Guide 10 projects project per leadership per trimester week Notes: 1 Expected effort for teams with novice GB and or BB, will be less for mature teams Ref: Page 3 of PI-II concept document 81 PI-II Team Composition Six Sigma Project Team Facilitator – 1 Black Belt 1 Green Belt 8-10 Yellow Belts Coach – Master Black Belt Ref: Page 2 of PI-II concept document 82 Typical PI-II Project Lifecycle • • • • • Define Measure Analyze Improve Control 2 sessions 1 session 2 sessions 2 sessions 1 session • Documentation 1 Month 2 weeks 1 Month 1 Month 2 weeks 1 week Anticipated timelines – some projects may take longer or shorter dependent on the maturity of the process (defined process, available data, etc.) and maturity of team members 83 PI-II Project Implementation Tool Structured Project Guide (SPG) • What – Structured project PLAN – Embedded TEMPLATES/TOOLS • Method When – TIMELINE driven How – TEMPLATES and What TASKLIST Who RESPONSIBLE Person • Use – Champion and MBB Project Tracker – BB Project Facilitation tool – GB Project guide and documentation tool – YB Tools and templates 84 PI-II Project Support Structure Support list with contact info on BU • Master Black Belt support – E-Mail/phone/consult support for Black Belts – Guides – weekly ½ hr project reviews with Black Belts/GBs – Monthly 2 hour open house – Q&A for Black Belts • Black Belt Support for Green Belts – E-Mail/phone/consult support for Green Belts – Project facilitation – facilitate 6s projects – 2 hrs per week • Green Belt Collaboration – HPIC/HCBC monthly lunch & learn meetings – share experiences – Quarterly GB colloquiums – Q&A with BBs and MBB – Annual 6s symposium – hear and learn Ref: Page 5 of PI-II concept document 85 PI-II Curriculum BU Course # Course Name Course available PI II Track Pilot course available Course Length Prerequisite Course needs to be rebuilt Nursing Contact Hrs Offering Class Comments size Course Status No course material available Yellow Belt Curriculum PI 100 Performance Improvement 100 Yellow 3.5 hours None Yes PI 200 Performance Improvement 200 Yellow 4 hours PI 100 Yes PI 300 Statistics and Control Charts Yellow 3 hours Excel course or quiz Yes PI 5000 Root cause Analysis Elective 2.5 hours None PI 350 Leader Curriculum Intro to Six Sigma for Project Sponsors and Champions Lean Curriculum Sponsor 4 hours None PI 400 Lean Tool Kit Lean 16 hours PI 100 -300 Elective 4 hours PI 100 - 300 PI 100 - 300 PI 500 Voice of Customer / Quality Function Deployment Green Belt Curriculum PI 600 Green Belt Green 6 weeks/24 hours PI 650 Internal SSGB Exam Green 4 hours Elective 2 hours 3 each trimester, 9/yr 3 each trimester, 9/yr 3 each trimester, 9/yr 1 each trimester, 3/yr 1 each trimester, 1/yr 1 each trimester, 1/yr 1 each trimester, 1/yr 1 each trimester, 1/yr 1 each trimester, 1/yr 35 Implemented 35 Implemented 15 Revised May 07 20 Implemented 35 To be developed/ Target rollout Sept 07 35 35 25 25 Pilot in progress/ Target rollout Oct 07 Pilot revision/ Target rollout Oct 07 Pilot revision/ Target rollout Oct 07 May be substituted with ASQ To be developed/ SSGB Certification Rollout Oct 07 Black Belt Curriculum PI 700 FMEA PI 800 Black Belt Black PI 900 SSBB Project Completion Black PI 1000 Internal SSBB Exam Black None 8 weeks/32 PI 100 – 300, hours 600, 650 Yes 1 each trimester, 1/yr 35 Implemented 2/yr 20 To be developed/ Rollout Jan 08 2 completed projects as GB 4 hours SPG Pilot 2/yr 20 TBD May be substituted with ASQ To be developed/ SSBB Certification Rollout Jan 08 Master Black Belt Curriculum PI 1100 Six Sigma Project Completion Master TBD PI 1200 Six Sigma Project Completion Master TBD PI 1300 Mentor Black Belt Project Master TBD To be developed/ Rollout Sept 08 To be developed/ TBD Investigate internal vs external Rollout Sept 08 curriculum To be developed/ TBD Rollout Sept 08 Ref: Page 4 of PI-II concept document 86 Certification Proposal • YB – Certified on completion of PI 100 + 200 + 300 & on-line test • GB (Progression certification) – Class + on-line test - multiple choice (certificate applicant) – Lead 1 successful Project (certificate candidate)/mentored – Internal Test (Certified – problem solving scenario test for GB) • BB (Progression certification) – Class (certificate applicant) – Facilitate 1 Project (certificate candidate)/mentor – Internal Test – written 4 hour with problems (Certified) • Lean (Application certification) – Class (certificate applicant) – Lead 1 successful Project (certificate candidate) – Internal Test – written 4 hour with a practical test/lean case (Certified) 87 PI-II Course Work Scheduling 2007-2008 BU Course # Course Name Plan Faculty Date Time Max Location Classroom Backup Faculty PI 100 Performance Improvement 100 Sep-07 Grace Bostic 9/21/07 AM 35 Royal Oak ro_abwest_ll_Clsrm3_Seats35 Lynn Farr PI 100 Performance Improvement 100 Sep-07 Kristen Cavender 9/10/07 AM 25 Troy Troy_Hosp_LL_Clrm3_Seats25 Kim Lemieux PI 100 Performance Improvement 100 Oct-07 Grace Bostic 10/29/07 AM 35 Royal Oak ro_abwest_ll_Clsrm3_Seats35 Kristen Cavender PI 100 Performance Improvement 100 Nov-07 Grace Bostic 11/13/07 AM 35 Barnum BARNUM_Mezz2_ClsrmCD_Seats35 Lynn Farr PI 100 Performance Improvement 100 Nov-07 Kim Lemieux 11/9/07 AM 25 Troy Troy_Hosp_LL_Clrm1_Seats25 Kristen Cavender PI 200 Performance Improvement 200 Sep-07 Randy Sprouse 9/21/07 PM 35 Royal Oak ro_abwest_ll_Clsrm3_Seats35 Lynn Farr PI 200 Performance Improvement 200 Sep-07 Kristen Cavender 9/10/07 PM 25 Troy Troy_Hosp_LL_Clrm3_Seats25 Kim Lemieux PI 200 Performance Improvement 200 Oct-07 Kristen Cavender 10/29/07 PM 35 Royal Oak ro_abwest_ll_Clsrm3_Seats35 Kim Lemieux PI 200 Performance Improvement 200 Nov-07 Randy Sprouse 11/13/07 PM 35 Barnum BARNUM_Mezz2_ClsrmCD_Seats35 Jayant Trewn PI 200 Performance Improvement 200 Nov-07 Kim Lemieux 11/9/07 PM 25 Troy Troy_Hosp_LL_Clrm1_Seats25 Kristen Cavender PI 300 Statistics and Control Charts Jul-07 Charles Phillips 7/10/07 AM 16 Troy Troy Computer Classroom PI 300 Statistics and Control Charts Jul-07 Jayant Trewn 7/17/07 AM 16 Barnum Computer Trg Room #2 PI 300 Statistics and Control Charts Jul-07 Jayant Trewn 7/24/07 AM 16 Barnum Computer Trg Room #2 PI 300 Statistics and Control Charts Sep-07 Wendy Dingwall 9/27/07 AM 25 Barnum Computer Trg Room #2 Jayant Trewn PI 300 Statistics and Control Charts Nov-07 Mike Meitzner 11/2/07 AM 16 Troy Troy Computer Classroom Jayant Trewn PI 300 Statistics and Control Charts Nov-07 Wendy Dingwall 11/14/07 AM 25 Barnum Barnum Computer Classroom 2 Jayant Trewn PI 310 Basic SPSS 7/19/08 AM 10 Barnum Computer Trg Room #2 PI 5000 Root Cause Analysis Sep-07 Lisa Wiethorn 9/19/07 9-11:30 am 25 Troy Troy_Hosp_LL_Clrm2_Seats25 PI 5000 Root Cause Analysis Nov-07 Lisa Wiethorn 11/16/07 1-3:30 pm 25 Troy Troy_Hosp_LL_Clrm1_Seats25 PI700 FMEA Jun-07 M. Getzinger/L.Wiethorn 25 Troy Troy_Hosp_LL_Clrm2_Seats25 Jayant Trewn PI 700 FMEA Sep-07 M. Getzinger/L.Wiethorn 9/7/07 9-11:00 am 25 Troy Troy_Hosp_LL_Clrm2_Seats25 Jayant Trewn PI 700 FMEA Nov-07 Randy Sprouse/Jayant Trewn 11/30/07 9-11:00 am 25 Royal Oak RO_ABWest_LL_Clsrm3_Seats35 Monique Getzinger PI600 Six Sigma Green Belt Sep-07 Jayant Trewn 25 Barnum Barnum_Classroom_C/D_Seats25 Jul-08 Jayant Trewn 6/22/07 9/10/07 AM AM 88 Q&A 89