File

advertisement

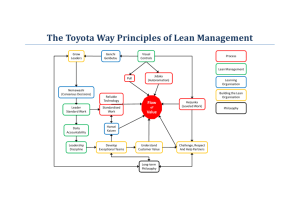

Lean Production Chapter 38 Definition Lean production is a collection of methods that attempt to reduce waste in the production process Benefits to lean production Reduced stock Improved quality Lower costs Reduced space requirements Shorter lead time Increased productivity Disadvantages Requires all staff to be in favour – staff find it hard to sustain the constant demand to improve and develop May not be able to meet customers demand – the need to reduce waste and minimise stock levels can leave to the reduction in ability to cope with customers demands Relies on a good supply chain Jaguar • At the Jaguar car production plant near Birmingham the production line has been designed using the principles of lean production. • Before, Jaguar use to use much more factory space because a lot of stocks and supplies were kept on the factory floor. • Now, all stocks are kept in a separate storage area where they are delivered just in time to feed the production process. • This increases efficiency for Jaguar and reduces cost and waste. So increasing profit for Jaguar. Toyota “lean manufacturing” A production system which is steeped in the philosophy of "the complete elimination of all waste" imbuing all aspects of production in pursuit of the most efficient methods. Toyota Motor Corporation's vehicle production system is a way of "making things" that is sometimes referred to as a "lean manufacturing system" or a "Just-inTime (JIT) system," and has come to be well known and studied worldwide.