PERT - Martsolf

advertisement

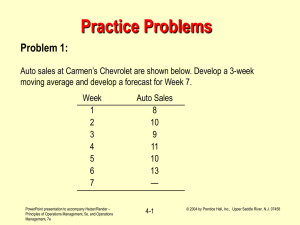

Chapter 13 Project Management To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-1 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Learning Objectives Students will be able to • Understand how to plan, monitor, and control projects with the use of PERT. • Determine earliest start, earliest finish, latest start, latest finish, and slack times for each activity along with the total project completion time. • Reduce total project time at the least total cost by crashing the network using manual or linear programming techniques. • Understand the important role of software in project management. To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-2 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Chapter Outline 13.1 Introduction 13.2 PERT 13.3 PERT/COST 13.4 Critical Path Method 13.5 Other Topics in Project Management To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-3 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Project Management Models • PERT • PERT/Cost • Critical Path Method To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-4 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Questions Addressed by PERT and CPM 1. When will the project be completed? 2. What are the critical activities or tasks in the project? 3. Which are the noncritical activities? 4. What is the probability that the project will be completed by a specific date? 5. Is the project on schedule, ahead of schedule, or behind schedule? 6. Is the project over or under the budgeted amount? To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-5 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Questions - continued 7. Are there enough resources available to finish the project on time? 8. If the project must be finished in less than the scheduled amount of time, what is the best way to accomplish this at least cost? To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-6 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Project Planning, Scheduling, and Controlling Project Planning 1. Setting goals 2. Defining the project 3. Tying needs into timed project activities 4. Organizing the team Project Scheduling 1. Tying resources to specific activities 2. Relating activities to each other 3. Updating and revising on regular basis Project Controlling 1. Monitoring resources, costs, Before Project During Project To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna quality and budgets 2. Revising and changing plans 3. Shifting resources to meet demands 13-7 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Six Steps Common to PERT and CPM 1. Define the project and all significant activities/tasks. 2. Develop relationships among the activities. Identify precedence relationships. 3. Draw the network. 4. Assign time and/or cost estimates to each activity. 5. Compute the longest time path (critical path) through the network. 6. Use the network to help plan, schedule, monitor, and control the project. To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-8 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Advantages of PERT/CPM • Useful at several stages of project management • Straightforward in concept, not mathematically complex • Uses graphical displays employing networks to help user perceive relationships among project activities • Critical path and slack time analyses help pinpoint activities that need to be closely watched To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-9 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Advantages - continued • Networks generated provide valuable project documentation and graphically point out who is responsible for various project activities • Applicable to a wide variety of projects and industries • Useful in monitoring not only schedules, but costs as well To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-10 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Limitations of PERT/CPM • Project activities must be clearly defined, independent, and stable in their relationships • Precedence relationships must be specified and networked together • Time activities in PERT are assumed to follow the beta probability distribution -must be verified • Time estimates tend to be subjective, and are subject to fudging by managers • There is inherent danger in too much emphasis being placed on the critical path To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-11 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry PERT Activity Description Immediate Predecessors A Build internal components B Modify roof and floor C Construct collection stack A D B F Pour concrete and install frame Build high-temperature burner Install control system G Install air pollution device D,E H Inspect and test F,G E To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-12 C C © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. PERT Network A 2 C Start 2 E B 3 D To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna F 4 4 13-13 3 H G 2 Finish 5 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Beta Probability Distribution with Three Time Estimates To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-14 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. Time Estimates Activity a m b 2 E(t) 2 A 1 2 3 2 B 2 3 4 3 C 1 2 3 2 D 2 4 6 4 E 1 4 7 4 F 1 2 9 3 G 3 4 11 5 H 1 2 3 2 1 3 1 6 9 2 1 4 1 4 6 2 1 3 1 6 9 2 4 6 2 9 6 2 9 7 1 6 9 2 16 9 1 9 6 2 25 11 1 6 92 1 3 1 6 9 Total: 25 weeks To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-15 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. PERT Network - with E(t) A 2 C 2 E 4 F 3 H 2 Start Finish B 3 D 3 G 5 ES LF LS LF To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-16 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. PERT Network ES/EF, LS/LF A 2 C 2 F 3 0 2 2 4 4 7 E 4 H 2 4 8 13 15 Start B 3 D 3 G 5 0 3 3 7 8 13 Finish ES LF LS LF To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-17 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. PERT Network ES/EF, LS/LF A 2 C 2 F 3 0 2 2 4 4 7 0 2 2 4 10 13 Start E 4 H 2 4 8 13 15 4 8 13 15 Finish B 3 D 3 G 5 0 3 3 7 8 13 ES LF 1 4 4 8 8 13 LS LF To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-18 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. Critical Path A 2 C 2 F 3 0 2 2 4 4 7 0 2 2 4 10 13 Start Total Time = 15 E 4 H 2 4 8 13 15 4 8 13 15 Finish B 3 D 3 G 5 0 3 3 7 8 13 ES LF 1 4 4 8 8 13 LS LF To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-19 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry Schedule & Slacks LF LS-ES On Critical Path? ES EF LS A 0 2 0 2 0 Yes B 0 3 1 4 1 No C 2 4 2 4 0 Yes D 3 7 4 8 1 No E 4 8 4 8 0 Yes G 4 7 10 13 6 No G 8 13 8 13 0 Yes H 13 15 13 15 0 Yes To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-20 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry Meeting a Deadline Standard z deviation, Due date - Expected project va riance completion date 16 - 15 0.57 1.76 0.57 Standard Deviations P(t 16 weeks) 71.6% 15 16 To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-21 Time - weeks © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 PERT Provided • Project expected completion date: 15 weeks • Probability of finishing in 16 or fewer days: 71.6% • Identity of activities on critical path: A, C, E, G, and H • Identity of activities with slack: B, D, and F • Detailed schedule of start/finish dates To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-22 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 PERT - Sensitivity Analysis Impact of Increase (Decrease) in Critical Path Activity time Activity Successor Parallel Time Activity Increase ES EF (decrease) Increase (decrease) Activity Predecessor Activity No change No change No change No change Increase LS Increase No change (Decrease) (decrease) Increase LF Increase No change (Decrease) (decrease) No Slack change To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna Increase No change (Decrease) 13-23 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Gantt Chart for General Foundry Activity 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 012 34 5 A B C D E F G H To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-24 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry, Inc. PERT & Budgeting ES LS) E(t) Total Budgeted Budgeted Cost per Cost Week A 0 0 2 $22,000 $11,000 B 0 1 3 $30,000 $10,000 C 2 2 2 $26,000 $13,000 D 3 4 4 $48,000 $12,000 E 4 4 4 $56,000 $14,000 F 4 10 3 $30,000 $10,000 G 8 8 5 $80,000 $16,000 H 13 13 2 $16,000 $ 8,000 Activity Total To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-25 $308,000 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry Budget Ranges To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-26 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 General Foundry Monitoring & Controlling To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-27 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Critical Path Method Steps in Project Crashing 1. Find normal critical path and identify critical activities. 2. Compute crash cost per week for all activities. 3. Select critical activity with smallest crash cost per week. Crash this activity 4. Check to make sure critical path is still critical. If not, find the new one. Return to step 3. To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-28 © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Normal Cost A 2 1 22,000 23,000 1,000 Yes B 3 1 30,000 34,000 2,000 No C 2 1 26,000 27,000 1,000 Yes D 4 3 48,000 49,000 1,000 No E 4 2 56,000 58,000 1,000 Yes G 3 2 30,000 30,500 500 No G 5 2 80,000 86,000 2,000 Yes H 2 1 16,000 19,000 3,000 Yes Normal Time Normal Cost General Foundry Normal/Crash Costs & Times To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 13-29 On the Critical Path? © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458 Crash & Normal Times and Costs Crash Cost Crash Activity Cost Cost Per Normal Week Crash Crash Cost - Normal 34000 Time Crash Time - 30000 3 -1 $34,000 $33,000 4000 2000 per week 2000 $32,000 Normal $31,000 $30,000 Normal Cost 1 Crash Time To accompany Quantitative Analysis for Management, 8e by Render/Stair/Hanna 2 3 Time (Weeks) Normal Time 13-30 Cost © 2003 by Prentice Hall, Inc. Upper Saddle River, NJ 07458