Fact Sheet - Balen Overpelt - Jan2014.indd

advertisement

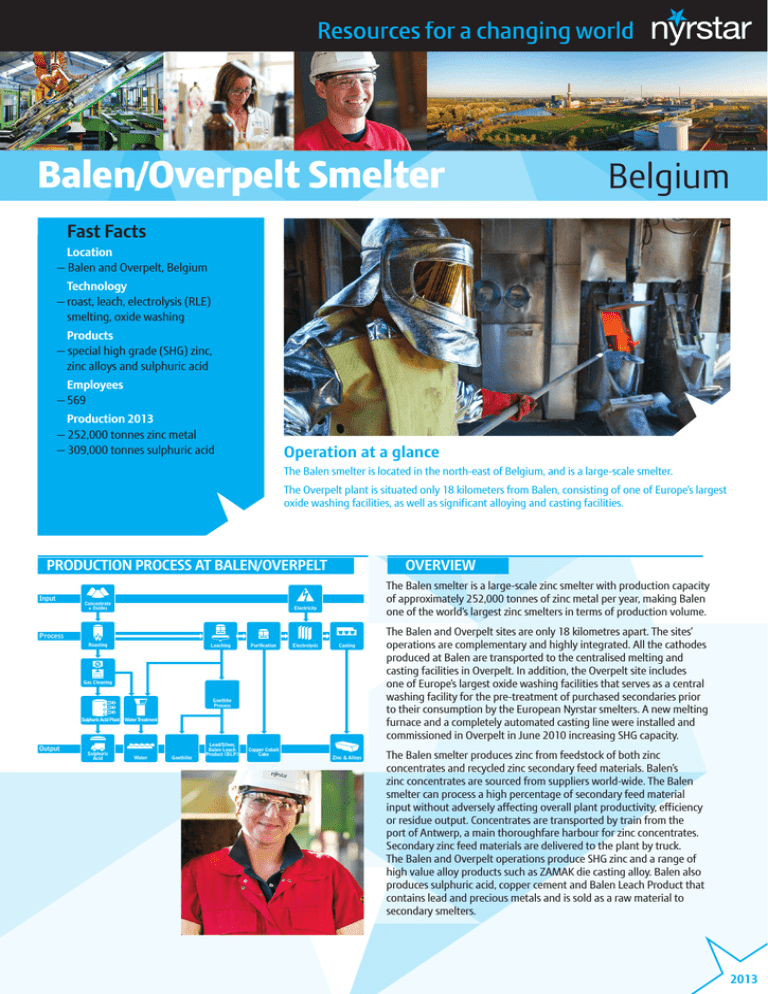

Balen/Overpelt Smelter Belgium Fast Facts Location — Balen and Overpelt, Belgium Technology — roast, leach, electrolysis (RLE) smelting, oxide washing Products — special high grade (SHG) zinc, zinc alloys and sulphuric acid Employees — 569 Production 2013 — 252,000 tonnes zinc metal — 309,000 tonnes sulphuric acid Operation at a glance The Balen smelter is located in the north-east of Belgium, and is a large-scale smelter. The Overpelt plant is situated only 18 kilometers from Balen, consisting of one of Europe’s largest oxide washing facilities, as well as significant alloying and casting facilities. PRODUCTION PROCESS AT LANGLOIS PRODUCTION PROCESS AT BALEN/OVERPELT Input Concentrate + Oxides OVERVIEW The Balen smelter is a large-scale zinc smelter with production capacity of approximately 252,000 tonnes of zinc metal per year, making Balen one of the world’s largest zinc smelters in terms of production volume. Electricity Process Roasting Leaching Purification Electrolysis Casting Gas Cleaning Goethite Process Sulphuric Acid Plant Water Treatment Output Sulphuric Acid Water Goethiite Lead/Silver, Balen Leach Product (BLP) Copper Cobalt Cake Zinc & Alloys The Balen and Overpelt sites are only 18 kilometres apart. The sites’ operations are complementary and highly integrated. All the cathodes produced at Balen are transported to the centralised melting and casting facilities in Overpelt. In addition, the Overpelt site includes one of Europe’s largest oxide washing facilities that serves as a central washing facility for the pre-treatment of purchased secondaries prior to their consumption by the European Nyrstar smelters. A new melting furnace and a completely automated casting line were installed and commissioned in Overpelt in June 2010 increasing SHG capacity. The Balen smelter produces zinc from feedstock of both zinc concentrates and recycled zinc secondary feed materials. Balen’s zinc concentrates are sourced from suppliers world-wide. The Balen smelter can process a high percentage of secondary feed material input without adversely affecting overall plant productivity, efficiency or residue output. Concentrates are transported by train from the port of Antwerp, a main thoroughfare harbour for zinc concentrates. Secondary zinc feed materials are delivered to the plant by truck. The Balen and Overpelt operations produce SHG zinc and a range of high value alloy products such as ZAMAK die casting alloy. Balen also produces sulphuric acid, copper cement and Balen Leach Product that contains lead and precious metals and is sold as a raw material to secondary smelters. 2013 Balen/Overpelt, and the world of Nyrstar Balen/Overpelt, Belgium AMSTERDAM THE NETHERLANDS Rotterdam Antwerp 12 Budel Balen/Overpelt BRUSSELS Lille Auby BELGIUM FRANCE Indicates neighbouring Nyrstar site THE WORLD OF NYRSTAR Nyrstar Balen/Overpelt is part of Nyrstar, an integrated mining and metals business with market leading positions in zinc and lead, and growing positions in other base and precious metals; Essential resources that are fuelling the rapid urbanisation and industrialisation of our changing world. Nyrstar has mining, smelting, and other operations located in Europe, the Americas, China and Australia and employs around 7,000 people. Nyrstar is incorporated in Belgium and has its corporate office in Switzerland. Nyrstar is listed on NYSE Euronext Brussels under the symbol NYR. Nyrstar is committed to providing a safe environment for our employees, minimising our smelters’ and mines’ impact on the environment and contributing to the communities in which we operate. HISTORY In 1888, the Balen site began production of calcine (roasted zinc ore) under the brand ‘Vieille Montagne’, followed by their first zinc production only two years later. In 1899, the roasting capacity doubled and a sulphuric acid plant was added. Between 1910 and 1976, the site operated as an integrated zinc-lead smelter organically growing to one of the largest roasting facilities in the world nine years later. For the last eight decades, the zinc smelter has used an electrolysis process to produce its zinc. The site chronologically operated under the name Vielle Montagne, Acec-Union Minière, Union Minière and Umicore - until Nyrstar was born in 2007. Since 1976, the main focus of the plant remains the production of zinc, zinc alloys and sulphuric acid. Contact Information Nyrstar Belgium Zinkstraat 1 2490 Balen Belgium T +32 14 44 95 00 F +32 14 81 73 12 www.nyrstarbalenoverpelt.be For more information please visit www.nyrstar.com or email communications@nyrstar.com. Learn about career opportunities at nyrstar.com/careers nyrstar.com © Nyrstar - January 2014